Shaft replacement guidelines – Goulds Pumps 7200CB - IOM User Manual

Page 86

Maintenance

In order to repair worn seats, skin cut them in a lathe while you maintain dimensional

relationships with other surfaces.

• Replace parts if the seats are defective.

Additional parts

Inspect and either repair or replace all other parts, if inspection indicates continued use would

be harmful to satisfactory and safe pump operation.

Inspection must include these items:

• Bearing end covers (109A and 119A)

• Labyrinth seals (332A and 333A)

• Bearing locknut (136)

• Impeller key (178) and coupling key (400)

• Bearing lockwasher (382)

• All nuts, bolts, and screws

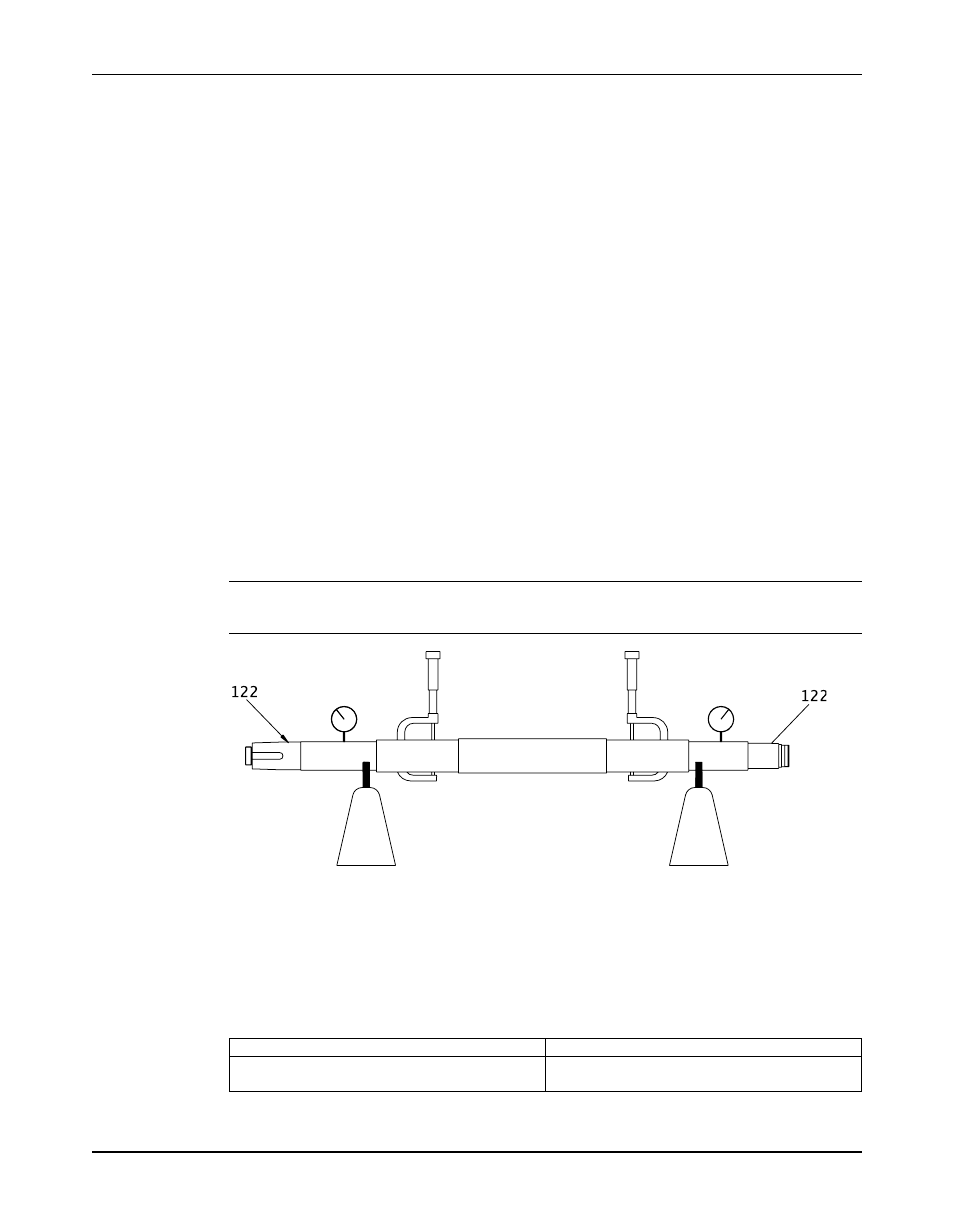

Shaft replacement guidelines

Shaft measurement check

Check the bearing fits of the shaft. If any are outside the tolerances shown in the Bearing fits

and tolerances table, then replace the shaft.

Shaft straightness check

Check the shaft straightness. Use "V" blocks or balance rollers to support the shaft on the

bearing fit areas. Replace the shaft if runout exceeds the values in the Shaft and rotor runout

requirements table.

NOTICE:Do not use shaft centers for the runout check as they may have been damaged during

the removal of the bearings or impeller.

Shaft surface check

Check the shaft surface for damage. Replace the shaft if it is damaged beyond reasonable

repair.

Rotor

Allowable runouts of the fully assembled rotor are listed in the Shaft and rotor runout

requirements table.

Table 3: Shaft and rotor runout requirements

Characteristic

Requirement

Flexibility factor, L

4

/D

2

>1.9x10

9

mm

(3.0x10

6

in.)

84

Model 7200CB, API Type BB5 Barrel Multistage / ISO 13709 2nd Edition / API 610 11th Edition Installation, Operation, and

Maintenance Manual