Goulds Pumps 3408 - IOM User Manual

Page 60

54

3408 IOM 03/99

Rotating Element Removal

12. For these procedures it will be necessary to remove

the line shafting or motor. Then remove the pump half

coupling.

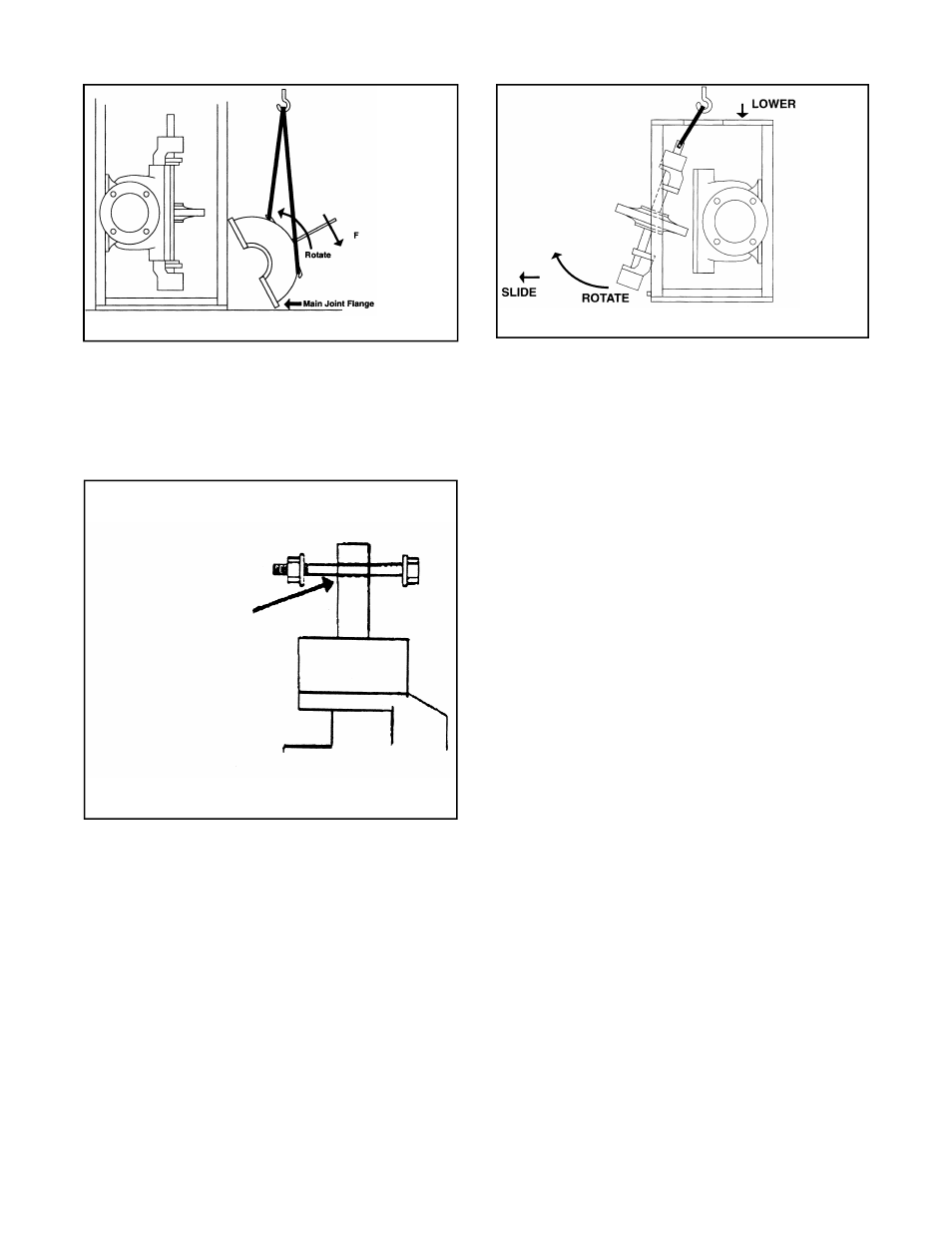

13. Thread a long bolt, washer and nut through the hole

at the end of the shaft. (See Fig. 56)

14. Sling around eye bolt, putting slight amount of

tension on sling.

15. Remove restraining straps if rotating element is not

securely fastened to casing lower half.

16. Lightly tapping on inboard and outboard bearing

housings, slide rotating element away from lower half.

17. Lower rotating element to ground by sliding outboard

bearing housing away from pedestal enabling element

to be set on floor with shaft in an horizontal position.

(See Fig. 57)

18. Rotating element can now be serviced following

disassembly procedure given previously in this

manual.

Reassembly of Rotating Element

19. Inspect main joint gasket and replace if

necessary. (Follow replacement instructions in

disassembly procedures section.)

20. Sling around the bolt in end of pump shaft.

21. On full pedestals, the lifting sling must come

through hole in top plate of pedestal.

(See Fig. 57)

22. When rotating element is off the ground and in

the vertical position, align any anti-rotation pins in

the casing rings and stuffing boxes for proper

orientation in the slots in the casing lower half.

23. Moving element towards casing lower half,

engage the stuffing box tongue first.

24. As the stuffing box tongue begins to go into the

respective casing fit, raise the inboard bearing

housing into its respective fit.

25. When the stuffing box tongues are firmly seated

in their respective fits and all the anti-rotation pins

are seated in their slots, restrain the rotating

element to the lower half.

Replacing Upper Casing Half

26. Sling around lifting ears and with stabilizer bar

installed, pick casing upper half off the ground

and rotate top half so that main joint flange is

vertical. (Reference Fig. 55 with rotation in

opposite direction shown.)

27. Move upper half towards lower half.

28. Prior to complete engagement of upper half onto

lower half, use dowel pins to guide the upper half

into its final exact position.

Fig. 55

Fig. 57

Fig. 56

COUPLING END OF

S H A F T D R I L L E D

THRU FOR A LONG

BOLT WITH NUT &

WASHER