Caution – Goulds Pumps 3408 - IOM User Manual

Page 42

38

3408 IOM 03/99

4.

Tap the stuff ing boxes with a soft-headed ham mer

to break the seal be tween the stuff ing box and lower

cas ing half, and lift the ro tat ing el e ment out of the

lower cas ing. Ro tating el e ment may now be moved

to a suit able work ing lo ca tion. (See Fig. 19)

NOTE: A spare rotating element can be

installed at this point.

5.

Re move four cap screws (3-904-9) from each

bear ing hous ing (3-025-3 and -4) and re move the

bear ing hous ings from the shaft (3-007-0).

6.

Bend back lockwasher tab and re move locknut

(3-516-4) and lockwasher (3-517-4) from the

out board end of the shaft and, us ing a puller,

re move the outboard bear ing (3-026-4) from the

shaft. Re move the in board end bear ing (3-026-3)

in the same man ner.

NOTE: Locknut and lockwasher are not used

on inboard end bearing.

▲

!

CAUTION

Do not reuse the ball bearings.

7.

Slide both stuff ing boxes (3-073-9) off of the shaft,

work ing de flec tor rings (3-136-9) off the shaft at

the same time. (See Fig. 20.)

8.

Re move lip seals (3-177-9) from the stuff ing

boxes.

9.

Re move the two gland bolts (1-904-9), gland

halves (1-014-9), pack ing (1-924-9) and, if

sup plied, seal cage (1-013-9) from each stuff ing

box. Re move the O-rings (3-914-1) from the

stuff ing boxes.

10. Re move the two cas ing rings (3-003-9) from the

im pel ler (4-002-0) and re move O-rings (3-914-2)

from each cas ing ring.

NOTE: Each casing ring on 8 x 10-20 and

10 x 12-18 has 2 O-rings. (See Fig. 21B, page 39)

11. Loosen set screw (3-902-3) in shaft nuts (3-015-9)

and then re move shaft nuts us ing pin span ner

wrench. Re move O-rings (3-914-9) from

counterbore in shaft sleeves.

NOTE: Both shaft nuts have right handed

threads.

12. To remove the sleeve, hold the shaft vertically

and tap it on a block of wood. The impeller weight

should force both the impeller and sleeve from the

shaft.

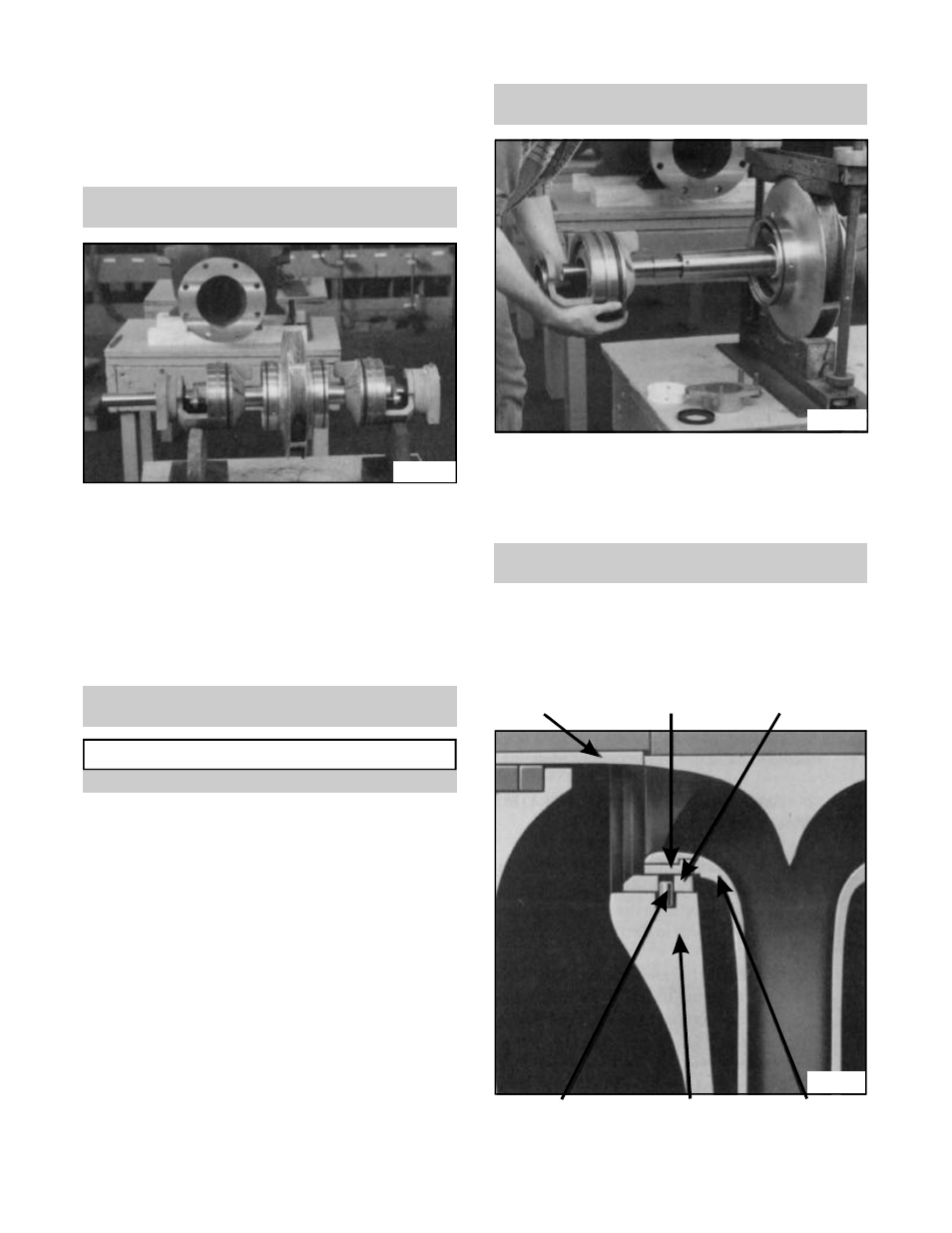

Fig. 20

(3-009-9)

SLEEVE

(0-004-0)

IMPELLER RING

(3-003-9)

CASING RING

LOCKING PIN

(3-943-9)

CASING

(2-001-0)

IMPELLER

(4-002-0)

Fig. 21A

Fig. 19