Caution – Goulds Pumps 3408 - IOM User Manual

Page 50

46

3408 IOM 03/99

14. Install lockwasher (3-517-4) and locknut(3-516-4)

on the outboard end of the shaft. Make certain

locknut is secured and then bend over tabs on

lockwasher.

15. Allow the bearing to cool to room temperature. On

grease lubricated bearings only, coat the exposed

sides with two or three ounces of recommended

grease.

16. On grease lubricated bearings, coat the inside of the

bearing housing (3-025-4) with grease and slide into

place over bearing. Attaching the bearing housing to

the stuffing box with four cap screws (3-904-9).

17. Repeat steps 9 through 13, 15 and 16 for the

inboard end.

NOTE: A locknut and lockwasher are not installed

on the inboard end of the shaft.

18. Clean the gasket surfaces of the casing. Apply

Scotch 3M-77 spray adhesive or equivalent to the

lower half of the casing.

19. Within one minute of spraying, set the untrimmed

gaskets (2-123-5 and -6) in place on the lower half

casing, align the holes in the gaskets with the holes in

the casing and press the gaskets firmly against the

lower half casing face in the area coated by the

adhesive.

20. Trim the gaskets flush with the lower casing bores, if

this has not been done as yet.

▲

!

CAUTION

Machined casing bores must remain sharp at the

casing parting line. Gaskets must be flush with

bore in order to contact O-rings. Leakage can

result around stuff box O-ring if this step is not

properly followed.

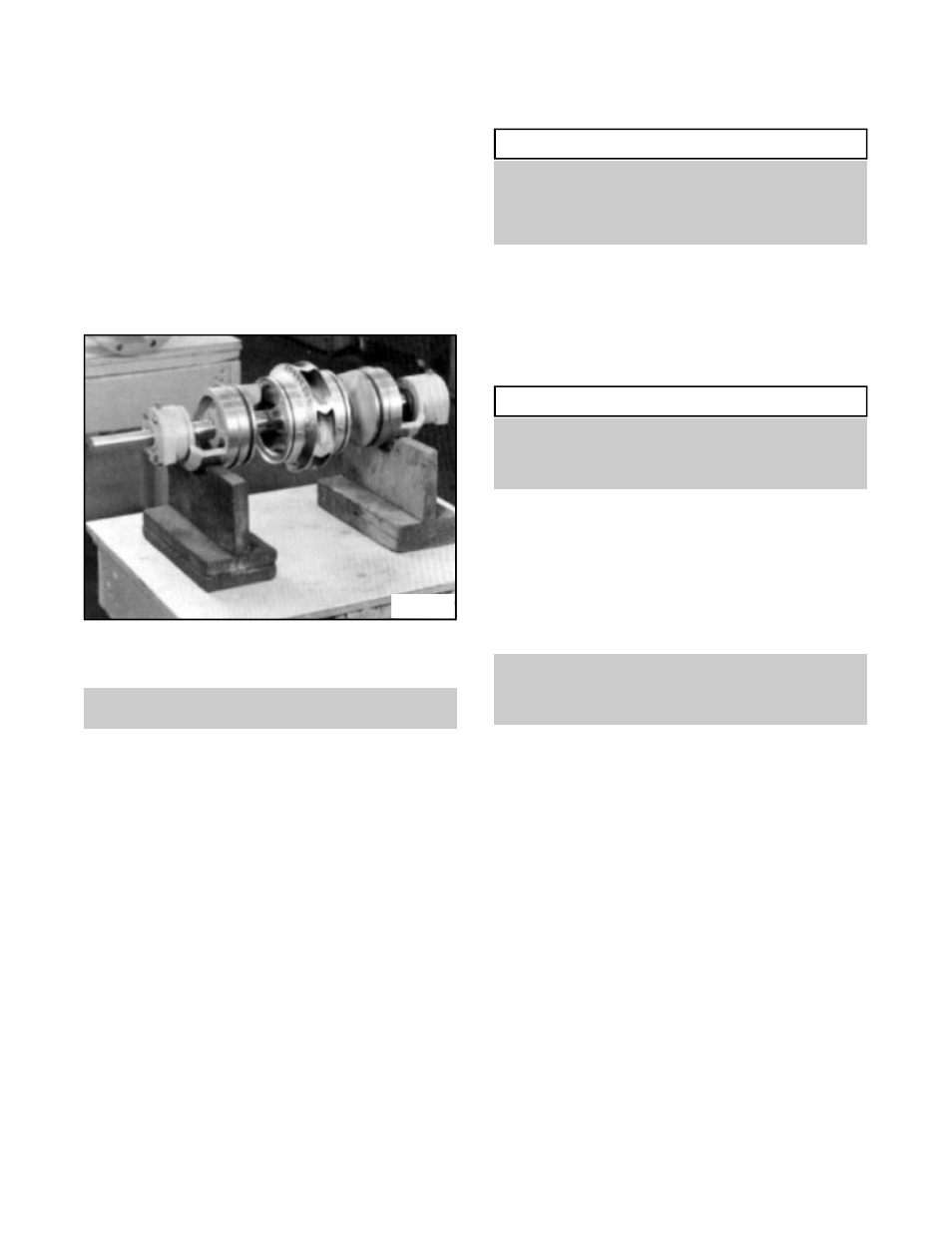

21. Set the rotating element (Fig. 38) in the pump

casing (2-001-0), assuring correct rotation. Locate

both stuffing box tongues in their respective

casing grooves. Locate pins (3-943-9) in the

stuffing box and the casing wear rings in their

respective slots at the casing parting surface.

Correct any O-ring bulging.

▲

!

CAUTION

Do not cut or damage O-rings when lowering the

rotating element into position. When all four

anti-rotation pins (3-943-9) are correctly located,

there will be some casing ring looseness.

22. Lower the upper half casing (2-001-0) into place

using the tapered dowel pins (2-916-1) and install

casing main joint bolts (2-904-1). The casing joint

bolts should be tightened to the following torques:

140 ft-lb minimum for 5/8"-11 hex head cap screws

(Grade 5); 350 ft-lb minimum for 7/8"-9 Ferry Cap

Countr-bor screws (Grade 8). bolt torquing pattern is

shown in Fig. 58, page 55.

NOTE: Torquing bolts to proper values in

proper sequence is essential in obtaining

proper gasket compression so no leakage can

occur at main joint.

23. Rotate the shaft by hand to assure that it turns

smoothly and is free from rubbing or binding.

24. Install seal water piping (0-952-0).

Fig. 38