Location, Foundation, Setting the baseplate – Goulds Pumps 3408 - IOM User Manual

Page 14

14

3408 IOM 03/99

LOCATION

The pump should be installed as near the suction

supply as possible, with the shortest and most direct

suction pipe practical. The total dynamic suction lift

(static lift plus friction losses in suction line) should not

exceed the limits for which the pump was sold.

The pump must be primed before starting. Whenever

possible, the pump should be located below the fluid

level to facilitate priming and assure a steady flow of

liquid. This condition provides a positive suction head

on the pump. It is also possible to prime the pump by

pressurizing the suction vessel.

When installing the pump, consider its location in

relation to the system to assure that sufficient Net

Positive Suction Head (NPSHA) is available at the

pump inlet connection. Available NPSH must always

equal or exceed the required NPSH (NPSHR) of the

pump.

The pump should be installed with sufficient accessibility

for inspection and maintenance. A clear space with ample

head room should be allowed for the use of an overhead

crane or hoist sufficiently strong to lift the unit.

NOTE: Allow sufficient space to be able to

dismantle pump without disturbing the pump inlet

and discharge piping.

Select a dry place above the floor level wherever

possible. Take care to prevent pump from freezing during

cold weather when not in operation. Should the possibility

of freezing exist during a shut-down period, the pump

should be completely drained, and all passages and

pockets where liquid might collect should be blown out

with compressed air.

Make sure there is a suitable power source available for

the pump driver. If motor driven, the electrical

characteristics of the power source should be identical to

those shown on motor data plate.

FOUNDATION

The foundation must be substantial enough to absorb

vibration. (Hydraulic Institute Standards recommends

the foundation weigh at least five (5) times the weight of

the pump unit.) It must form a permanent and rigid

support for the baseplate. This is important in

maintaining the alignment of a flexibly coupled unit.

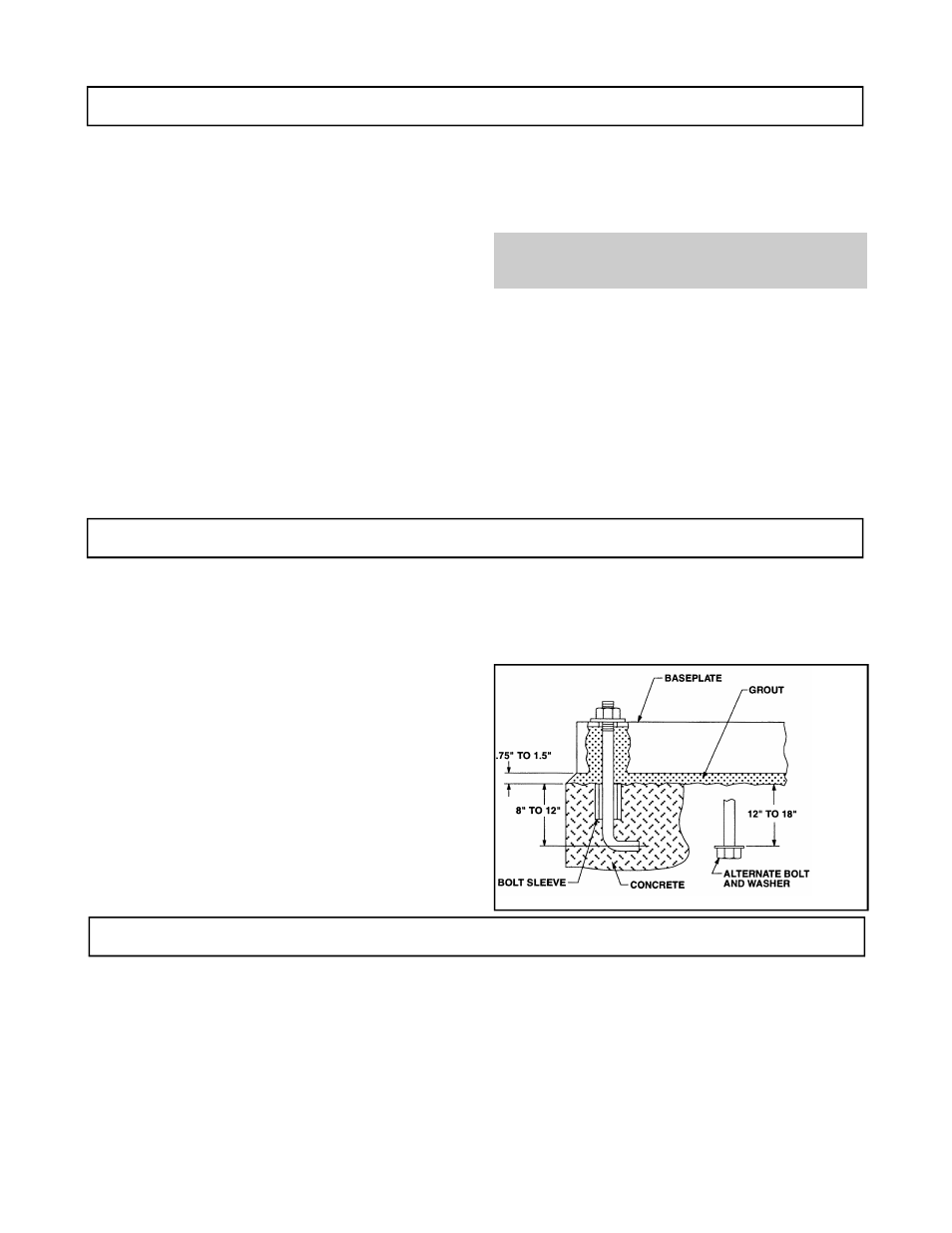

Foundation bolts of the proper size should be embedded

in the concrete to a depth of eight (8) to twelve (12)

inches and locked with either a hook around a

reinforcing bar or alternatively, a nut and washer at the

bottom. The bolts should have a sleeve around them at

least six (6) times the bolt diameter in length and at least

two (2) bolt sizes larger in I.D. If a nut and washer are

used for locking, the washer should have an O.D. two

(2) sizes larger than the sleeve. Foundation bolts should

be sized .125" less than the anchor bolt holes in the

base.

The foundation should be poured to within .75" - 1.5"

of the finished height. (See Fig. 8) Freshly poured

foundations should be allowed to cure for several

days before the unit is set in place and grouted.

SETTING THE BASEPLATE

Pump units are checked at the factory for align ability to

required tolerances.

Due to flexibility of an ungrouted base and handling in

shipment, it should not be assumed that the unit is in

alignment when it is placed on the rough foundation.

If these directions are followed, the required alignment

should be readily achieved.

Initial or rough alignment must be done prior to grouting of

baseplate. Rough alignment is designated as .020" TIR

(Total Indicator Reading) parallel alignment and .009" TIR

per inch of radius angular alignment (See ALIGNMENT

PROCEDURE). Use blocks at anchor bolts and midway

between to position bottom of base at finished height

(See Fig. 9) with foundation bolts extending through holes

in the baseplate. Metal wedges with a small taper may be

used in lieu of blocks and shims.

Fig. 8