Suction and discharge piping, Doweling – Goulds Pumps 3408 - IOM User Manual

Page 17

3408 IOM 03/99

17

3

SUCTION AND DISCHARGE PIPING

The introduction of pumpage into a piping system which is

not well designed or adjusted may cause strain on the

pump, leading to misalignment or even impeller rubbing.

Since slight strain may go unnoticed, final alignment should

be done with the system full and up to final temperature.

Pipe flanges should not impose any strain on the pump.

This can be checked by a dial indicator. Any strain must be

corrected by adjustments in the piping system.

When installing the pump piping, be sure to observe the

following precautions:

Piping should always be run to the pump.

Do not move the pump to pipe. This could make final

alignment impossible.

Both the suction and discharge piping should be

independently anchored near the pump and properly

aligned so that no strain is transmitted to the pump when

the flange bolts are tightened. Use pipe hangers or other

supports at necessary intervals to provide support. When

expansion joints are used in the piping system they must be

installed beyond the piping supports closest to the pump.

Tie bolts and spacer sleeves should be used with

expansion joints to prevent pipe strain. Do not install

expansion joints next to the pump or in any way that would

cause a strain on the pump resulting from system pressure

changes. When using rubber expansion joints, follow the

recommendations of the Technical Handbook on Rubber

Expansion Joints and Flexible Pipe Connectors. It is usually

advisable to increase the size of both suction and discharge

pipes at the pump connections to decrease the loss of head

from friction.

Install piping as straight as possible, avoiding unnecessary

bends. Where necessary, use 45° or long radius 90° fittings

to decrease friction losses.

Make sure that all piping joints are air-tight.

Where flanged joints are used, assure that inside diameters

match properly.

Remove burrs and sharp edges when making up joints.

Do not “spring” piping when making any connections.

Provide for pipe expansion when hot fluids are to be

pumped.

DOWELING

Pump units may, if desired, (or required in

specification) be doweled on diagonally opposite feet.

This should not be done until the unit has been run for

a sufficient length of time and alignment is within the

above alignment tolerance.

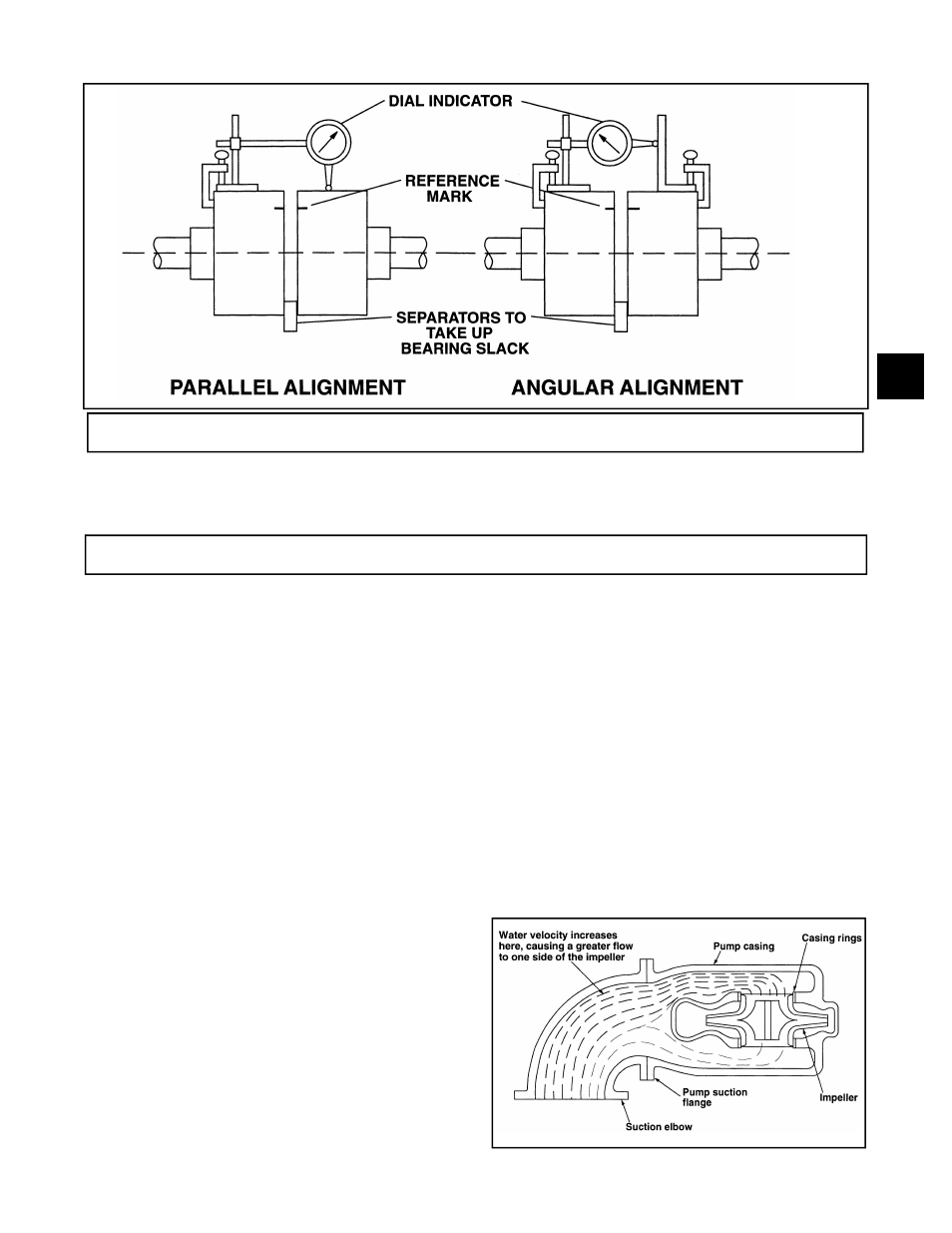

Fig. 11

Fig. 12