Pulsafeeder Pulsa GLM DM1-6 User Manual

Page 16

12

4.3.3

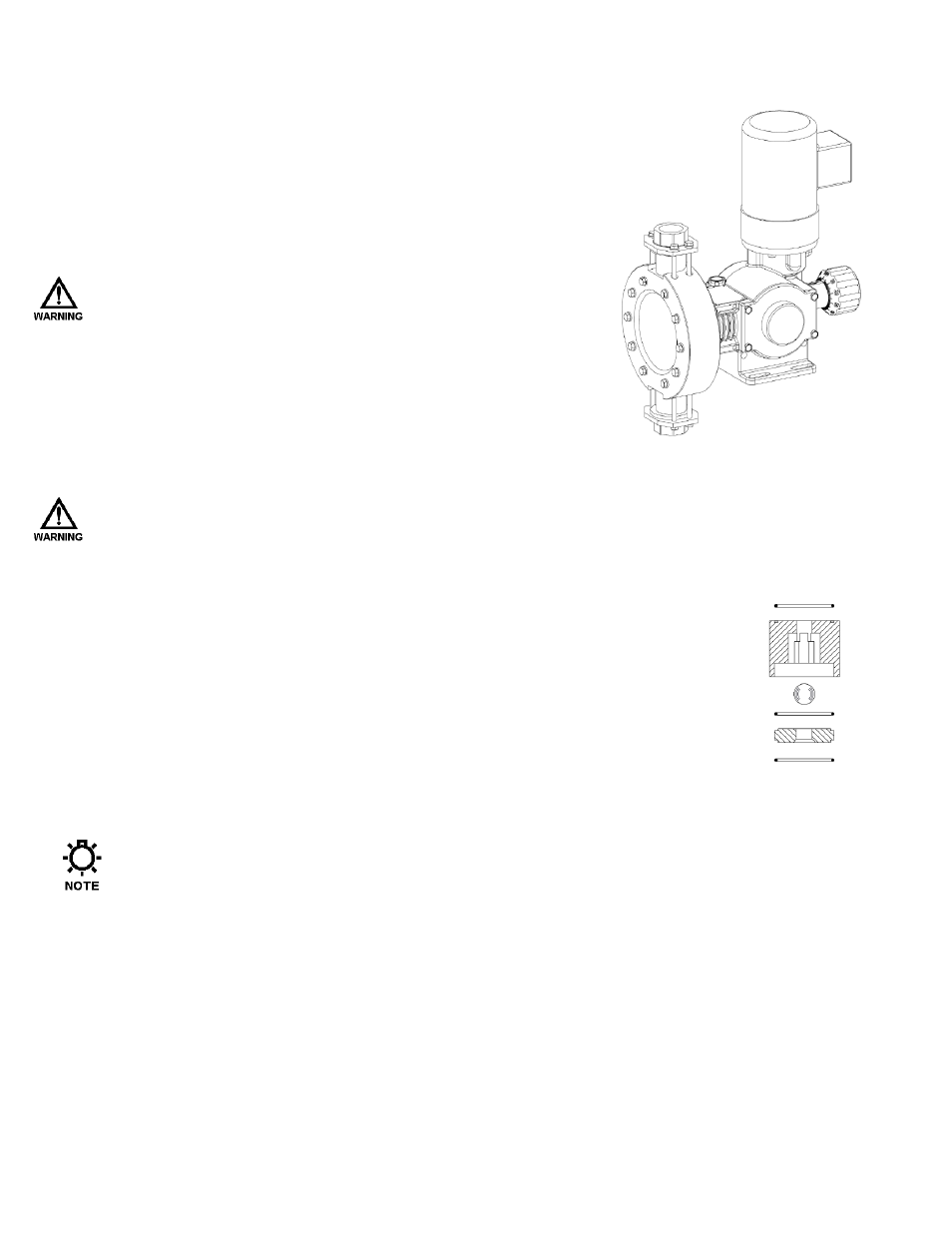

Check Valve Removal & Reinstallation, Tie-bar type

1. Disconnect and Lockout the power supply to the drive motor.

2. Relieve all pressure from the piping system.

3. Take all precautions necessary to prevent contamination to the

environment and personnel exposure to hazardous materials.

4. Close the inlet and outlet shutoff valves.

5. Loosen the suction valve tie-bar bolts (4) and spring the suction

piping slightly away from the head, allowing liquid to drain. It

may be necessary to loosen a union or flange.

Caution – Process fluid may drain from the Piping. Take

necessary precautions.

6. Remove the suction check valve assembly by sliding it towards

you, holding it together as a unit. Note carefully the position of

the component parts, to assist in re-assembly.

7. Loosen the discharge valve tie-bar bolts (4) and spring the

discharge piping slightly away from the head, allowing liquid to

drain. It may be necessary to loosen a union or flange.

Caution – Process fluid may drain from the Piping. Take necessary precautions.

8. Remove the discharge check valve assembly by sliding it towards you, holding it

together as a unit. Note carefully the position of the component parts, to assist in

re-assembly.

9. Disassemble both valves and check components for wear or damage. The seats

should have a sharp edge and be free from dents or nicks. Hold a ball firmly

against the seat in front of a bright light and inspect for fit. Observation of light

between the ball and seat is cause for replacement.

10. Reassemble both valves using new parts as required. Sealing o-rings should

always be replaced.

11. Replace both valve assemblies onto the pump, taking care to ensure they are

oriented correctly, with the balls above the seats, and the seats oriented with the sharp edge up and

the chamfered edge down.

Inserting the check valve assmbly into the pump in the wrong

directiom, or having the check seat upside down, will prevent proper

seals at the o-rings, decrease pump performance, and can cause

damage to the diaphragm.

12. Carefully make sure that the check assemblies are in proper position, and tighten the four tie-bar bolts,

using a star pattern, to a torque of 6 Ft-lbs (8 N-m).

13. Retighten any unions, flanges, or other process connections that may have been loosened previously.

Figure 14: Tie Bar Style Metal

Valves

Figure 15: Metal

Valve