2 wet end removal, inspection, & reinstallation, Wet end removal, inspection, & reinstallation – Pulsafeeder Pulsa GLM DM1-6 User Manual

Page 13

9

4.2

Wet End Removal, Inspection, & Reinstallation

I

F THE DIAPHRAGM HAS FAILED

,

PROCESS FLUID MAY HAVE CONTAMINATED OTHER PARTS OF THE PUMP

INCLUDING THE DRIVE COMPONENTS

(

ALTHOUGH NORMALLY

,

ANY PROCESS FLUID BEHIND A FAILED

DIAPHRAGM WOULD PASS THROUGH THE BOTTOM DRAIN HOLE

).

H

ANDLE WITH APPROPRIATE CARE

.

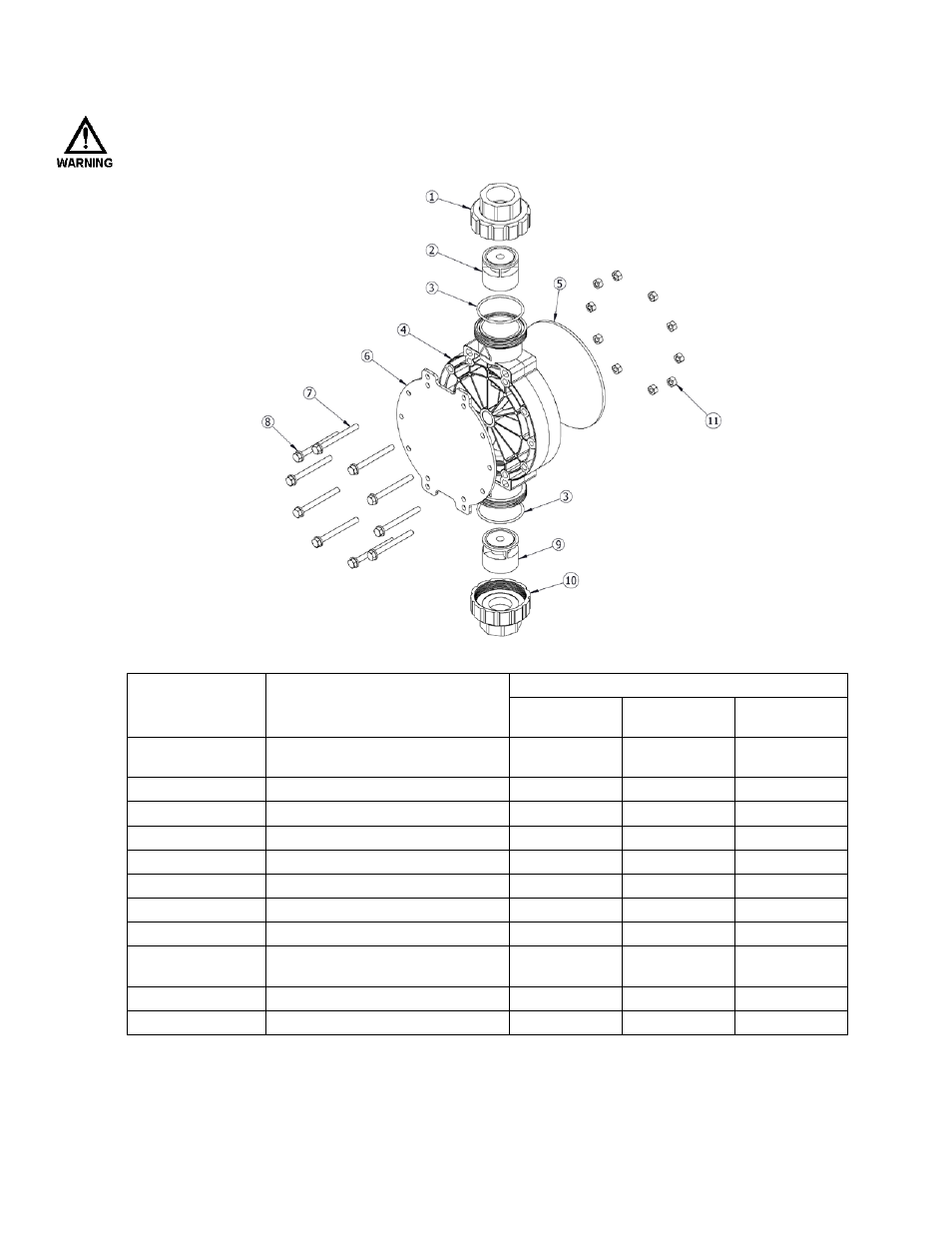

Figure 11: Wet End Components

Item

Description

Qty.

DM1 and

DM2

DM3 and

DM4

DM5 and

DM6

1

Discharge Connection

Assembly

1

1

1

2

Discharge Valve Assembly

1

1

1

3

O-ring

2

2

2

4

Reagent Head

1

1

1

5

Diaphragm

1

1

1

6

Front Cover Plate

1

1

1

7

Hex Head Bolt

8

10

12

8

Flat Washer

8

10

12

9

Suction Check Valve

Assembly

1

1

1

10

Suction Connection Assembly

1

1

1

11

Hex Nuts

8

10

n/a

PULSA GLM

®

diaphragms do not have a specific cycle life; however, the accumulation of foreign

material or debris sufficient to deform the diaphragm can eventually cause failure. Failure can also

occur as a result of system over pressure or chemical attack. Periodic diaphragm inspection and

replacement are recommended. Each user should perform regular inspections to determine the

replacement interval that is appropriate to their system conditions.