3 check valves, 1 general description, Check valves – Pulsafeeder Pulsa GLM DM1-6 User Manual

Page 15

11

4.3

Check Valves

4.3.1

General Description

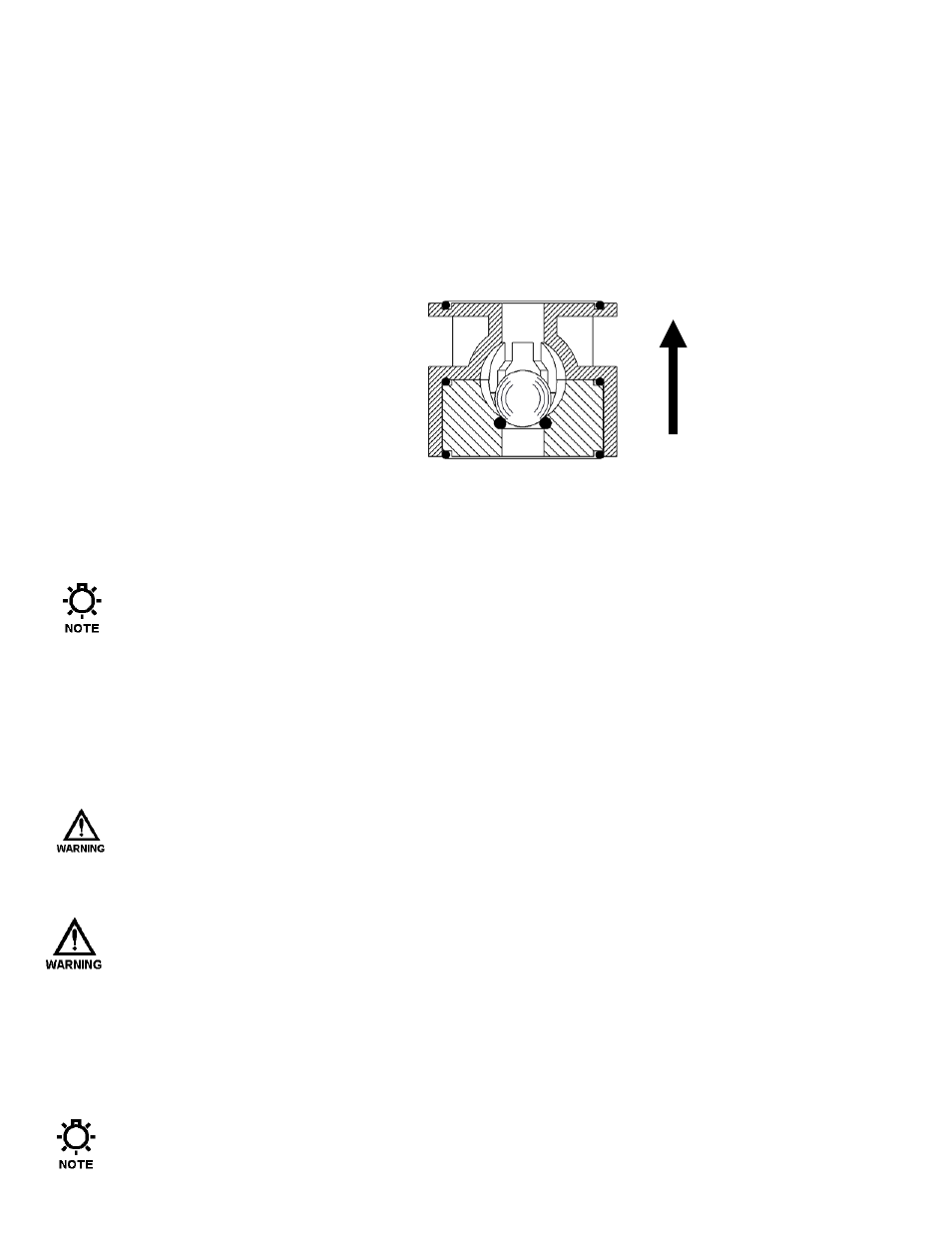

The valve incorporates a ball, guide, and seat. Flow in the unchecked direction lifts the ball off the

seat, allowing liquid to pass through the guide. Reverse flow forces the ball down, sealing it against

the bevel edge of the seat and o-ring. The guide permits the ball to rotate but restricts vertical and

lateral movement in order to minimize “slip” or reverse flow. Ball rotation prolongs life by distributing

wear over the entire surface of the ball. Since ball return is by gravity, the valve must be in the vertical

position in order to function properly. Parts are sealed by o-rings.

Figure 13: Cartridge Check Valve

4.3.2

Check Valve Removal & Reinstallation, Cartridge type

Valving that is of the cartridge design is intended to be replaced as an assembly.

1. Disconnect and Lockout the power supply to the drive motor.

2. Relieve all pressure from the piping system.

3. Take all precautions necessary to prevent contamination to the environment and personnel exposure

to hazardous materials.

4. Close the inlet and outlet shutoff valves.

5. Disconnect the suction piping at the suction shut-off valve union by releasing the union retaining nut.

Caution – Process fluid may drain from the Piping. Take necessary precautions.

6. Disconnect the discharge piping at the discharge shut-off valve union by releasing the union retaining

nut.

Caution – Process fluid may drain from the piping. Take necessary precautions.

7. Loosen and remove the suction valve cartridge retaining nut and drain any liquid from the reagent

head.

8. Disconnect the discharge piping at the installed union near the discharge port.

9. Loosen and remove the discharge valve cartridge slowly to drain any trapped liquid.

10. Reinstall both new valve assemblies. For both the suction and discharge the valve orientation should

be as shown in Figure 13.

Take care to assure o-rings are fully seated in groves and are not displaced during assembly. A pinched

o-ring can cause the assembly to leak. If necessary use a compatible o-ring retaining compound.

Direction of

Flow (UP)