4 calibration, Maintenance, Calibration – Pulsafeeder Pulsa GLM DM1-6 User Manual

Page 11: Aintenance

7

3.4

Calibration

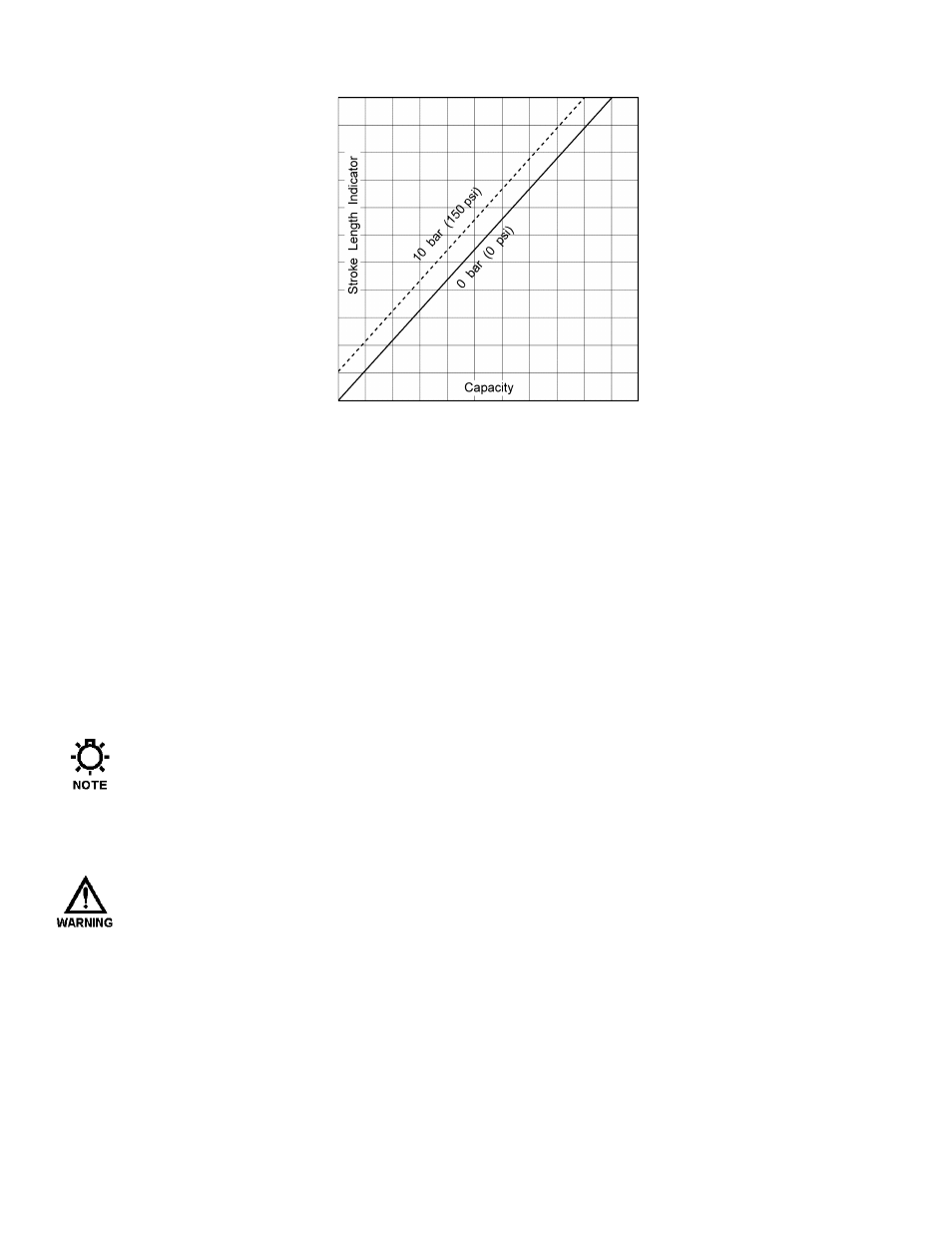

Figure 8: Sample Flow Calibration Curve

All metering pumps must be calibrated to accurately correlate stroke length settings to measured flow

rates.

A typical calibration chart is shown above. Although output is linear with respect to the stroke length

setting, an increase in discharge pressure decreases output uniformly, describing a series of parallel

lines, one for each pressure (only two are shown).

The theoretical output flow rate at atmospheric discharge pressure is based on the displacement of the

diaphragm, stroke length and the stroking rate of the pump. With increasing discharge pressure there is

a corresponding decrease in output flow. Pumps are rated for a certain flow at a rated pressure (check

nameplate). Whenever possible, calibration should be performed under actual process conditions (i.e.,

the same or a similar process liquid at system operating pressure).

To construct a calibration chart, measure the flow rate several times at three or more stroke settings

(e.g., 25, 50, 75, and 100), plot these values on linear graph paper, and draw a best-fit line through the

points. For stable conditions, this line should predict settings to attain required outputs.

Note - All users are encouraged to test the flow rate of their pump once installed in their system,

to ensure best accuracy and reliable operation.

4. Maintenance

B

EFORE PERFORMING ANY MAINTENANCE REQUIRING REAGENT HEAD OR VALVE

(

WET END

)

DISASSEMBLY

,

BE SURE TO RELIEVE PRESSURE FROM THE PIPING SYSTEM AND

,

WHERE HAZARDOUS

PROCESS MATERIALS ARE INVOLVED

,

RENDER THE PUMP SAFE TO PERSONNEL AND THE ENVIRONMENT

BY CLEANING AND CHEMICALLY NEUTRALIZING AS APPROPRIATE

.

W

EAR PROTECTIVE CLOTHING AND

EQUIPMENT AS APPROPRIATE

.

Accurate records from the early stages of pump operation will indicate the type and levels of required

maintenance. A preventative maintenance program based on such records will minimize operational

problems. It is not possible to forecast the lives of wetted parts such as diaphragms and check valves.

Since corrosion rates and operational conditions affect functional material life, each metering pump must

be considered according to its particular service conditions.

The PULSA GLM

®

KOPkit will contain all replacement parts normally used in a preventative maintenance

program. It is recommended that KOPkits and PULSAlube 9M be kept available at all times.