Replacement, Pulley and belt replacement, Bearing replacement – COOK SQN User Manual

Page 7: Wheel replacement, Maximum rpm

7

Pulley and Belt Replacement

a. Remove pulleys from their respective shafts.

b. Clean the motor and fan shafts.

c. Clean bores of pulleys and coat the bores with heavy

oil.

d. Remove grease, rust, or burrs from the pulleys and

shafts.

e. Remove burrs from shaft by sanding.

f. Place fan pulley on fan shaft and motor pulley on its

shaft.

NOTICE! Do not hammer the pulleys onto the shafts

because this may damage the bearings.

g. Tighten in place.

h. Install belts on pulleys and align as described in the

Belt and Pulley Installation section.

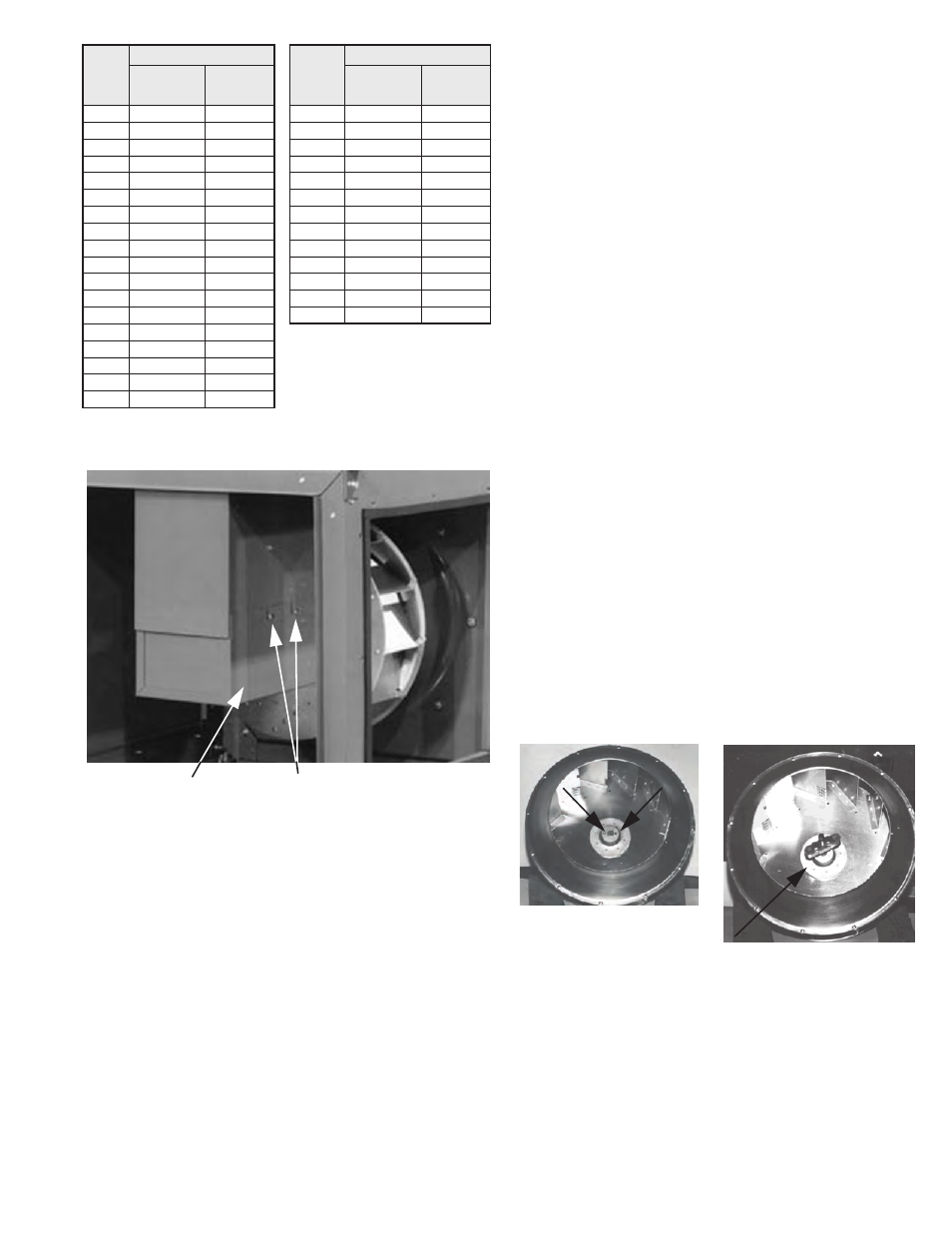

Bearing Cover Screws (Several screws on

opposite side not shown in photograph.)

Bearing Cover

Maximum RPM

SQN-B

Size

Maximum RPM

SQN-HP

Size

Maximum RPM

Non

Reinforced

Wheel

Reinforced

Wheel

Non

Reinforced

Wheel

Reinforced

Wheel

60

3795

-

135

2622

-

70

4006

-

150

2929

-

80

3409

-

165

2635

-

100

3243

-

180

2169

-

120

2867

-

195

1955

-

135

2332

-

210

1781

-

150

2099

-

225

1500

1861

165

1833

2107

245

1185

1773

180

1610

1786

270

1025

1563

195

1429

1593

300

980

1204

210

1277

1399

330

830

1178

225

1152

1459

365

735

1038

245

1015

1434

402

630

970

270

876

1226

300

837

1024

330

716

962

365

624

786

402

539

683

Bearing Replacement

The fan bearings are pillow block ball bearings.

a. Loosen screws on bearing cover.

b. Push bearing cover toward the wheel. As the bearing

cover moves toward the wheel it will slide down to

reveal the bearings and shaft. Refer to Figure 6.

c. Remove the old bearing.

d. Remove any burrs from the shaft by sanding.

e. Slide new bearings onto the shaft to the desired loca-

tion and loosely mount bearings onto the bearing

support. Bearing bolts and setscrews should be loose

enough to allow shaft positioning.

f. Correctly position the wheel and tighten the bearing

bolts securely to the bearing support.

g. Align setscrews bearing to bearing and secure tightly

to the shaft.

NOTICE! Never tighten both pairs of setscrews

before securing bearing mounting bolts. This may

damage the shaft.

h. Inspect the wheel position again. If necessary, read-

just by loosening the bearing bolts and setscrews and

repeat from step e.

Wheel Replacement

a. Drill two 1/4” diameter holes, 180° apart centered

approximately between the shaft and the outside

diameter of the hub, 3/8” to 1/2” in depth.

b. Tap 1/4” holes to 5/16” thread with a 5/16” hole tap.

Do not drill or tap greater than recommended.

c. Screw the puller arms to the full depth of the threads

into the tapped holes. Align center of the puller with

the center of the shaft. Ensure all setscrews in the

hub, normally two, are fully removed.

d. Slowly remove wheel from the shaft.

Recommended Puller

Lisle No. 45000 Sterling Wheel Puller. This puller is avail-

able at most automotive parts retail outlets.

Wheel Replacement Components

Above - Drilled hole placement.

Right - Wheel puller.