Side discharge, Operation, Maintenance – COOK SQN User Manual

Page 4: Start up, Inspection

4

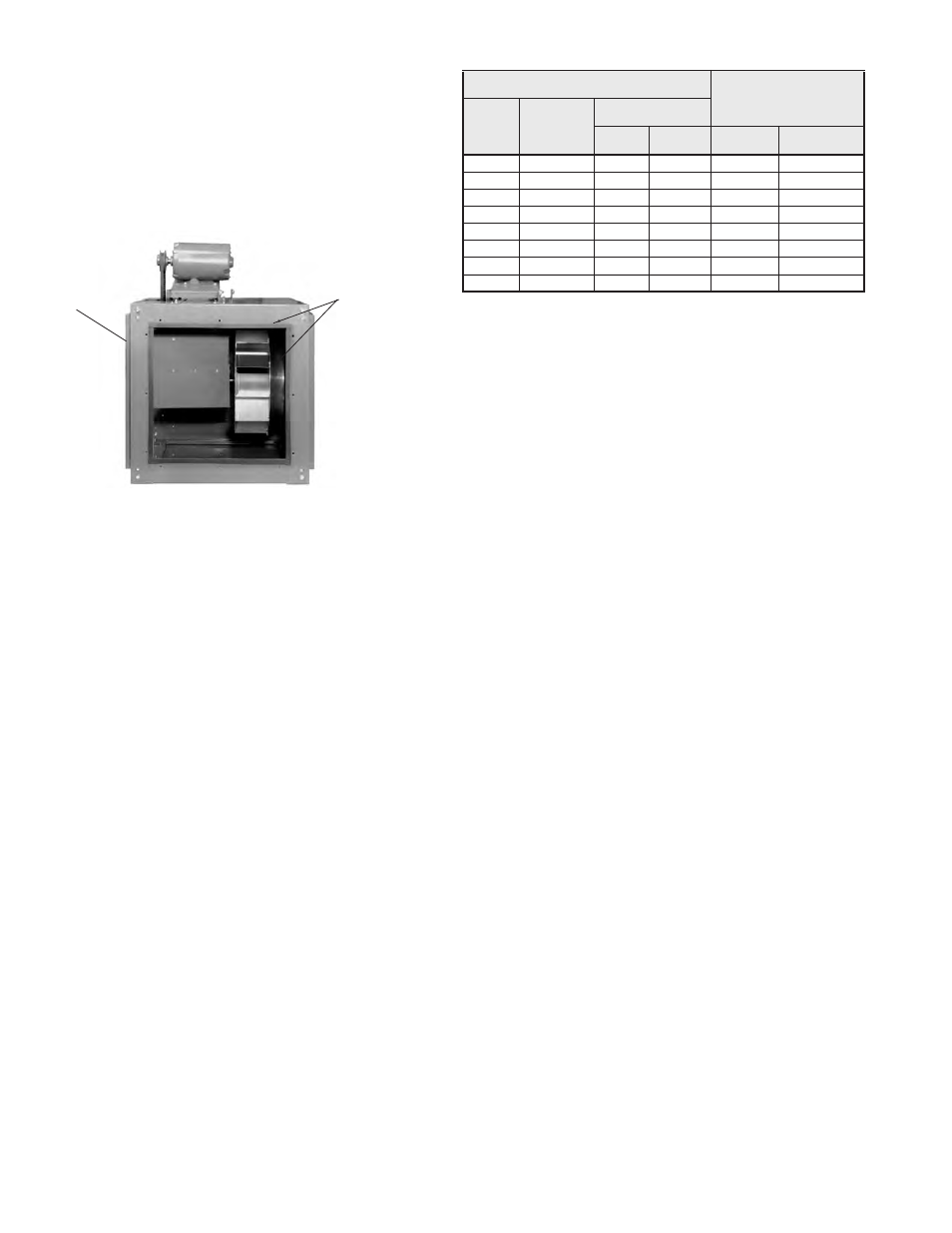

SQN Optional Side Discharge Installation

Upon receiving a SQN for a side discharge installation,

please note that the rear discharge block-off panel is

installed on the unit and that the correct number of side dis-

charge duct connection collars are provided (4 steel

flanges for a single side discharge and 8 for dual).

To install the side discharge duct connection collar,

remove the appropriate access door. Install the side dis-

charge duct connection collar using the bolts that were

removed with the access door. Then connect the duct work.

See page 5 for examples.

NOTICE! Original Loren Cook Company labels must

remain with the unit. This may require swapping

access doors from one side to the other.

Final Installation Steps

a. Ensure that all accessories are installed.

b. Ensure that the blower is secured to ductwork.

c. Inspect wheel-to-inlet clearance. Ensure wheel does

not rub against the inlet.

d. Test the fan to ensure the rotation of the wheel is the

same as indicated by the rotation label.

e. Inspect for correct amperage with an ammeter and

correct voltage with a voltmeter.

NOTICE! Do not allow the fan to run in the wrong

direction. This will overheat the motor and cause seri-

ous damage. For 3-phase motors, if the fan is running

in the wrong direction, check the control switch. It is

possible to interchange two leads at this location so

that the fan is operating in the correct direction.

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power

sources.

b. Inspect and tighten fasteners and setscrews, particu-

larly fan mounting and bearing fasteners. Refer to

Torque chart.

c. Inspect belt tension and pulley alignment.

d. Inspect motor wiring.

e. Ensure fan and ductwork are clean and free of

debris.

f. Close and secure all access doors.

g. Restore power to the fan.

Side Discharge

Duct Connection

Collar

Rear Discharge

Block-off Panel

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed and inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Bearing noise.

• Improper belt alignment or tension (listen for squeal-

ing).

• Improper motor amperage or voltage.

NOTICE! If a problem is discovered, immediately shut

the fan off. Lock out all electrical power and check for

the cause of the trouble. See Troubleshooting on page

7.

Inspection

Inspection of the fan should be conducted at the first 30

minute, 8 hour and 24 hour intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as per

the chart below.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension. Adjust and tighten as necessary.

Maintenance

Establish a schedule for inspecting all parts of the fan.

The frequency of inspection depends on the operating con-

ditions and location of the fan.

Inspect fans exhausting corrosive or contaminated air

within the first month of operation. Fans exhausting con-

taminated air (airborne abrasives) should be inspected

every three months.

Yearly inspections are recommended for fans exhausting

non-contaminated air.

It is recommended the following inspections be con-

ducted twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary. Refer to Torque chart.

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. Refer

to Belt and Pulley Installation.

• Bearings should be inspected as recommended in the

Conditions Chart.

Recommended Torque for Setscrews/Bolts (IN/LB.)

Setscrews

Hold Down Bolts

Size

Key Hex

Across

Flats

Recommended

Torque

Min.

Max.

Size

Wrench

Torque

No.10

3/32”

28

33

3/8”-16

240

1/4”

1/8”

66

80

1/2”-13

600

5/16”

5/32”

126

156

5/8”-11

1200

3/8”

3/16”

228

275

3/4”-10

2100

7/16”

7/32”

348

384

7/8”-9

2040

1/2”

1/4”

504

600

1”-8

3000

5/8”

5/16”

1104

1200

1-1/8”-7

4200

3/4”

3/8”

1440

1800

1-1/4”-7

6000