Installation, Wiring diagrams – COOK SQN User Manual

Page 2

2

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection

Motor

1

2

3

4

5

6

Together

High Speed

Line

L1

L2

L3

1

2

3

4

5

6

Open

Low Speed

Line

L1

L2

L3

Motor

Fan

Motor

Damper

Motor*

Second

Damper

Motor

Transformer**

Transformer**

L3

L2

L1

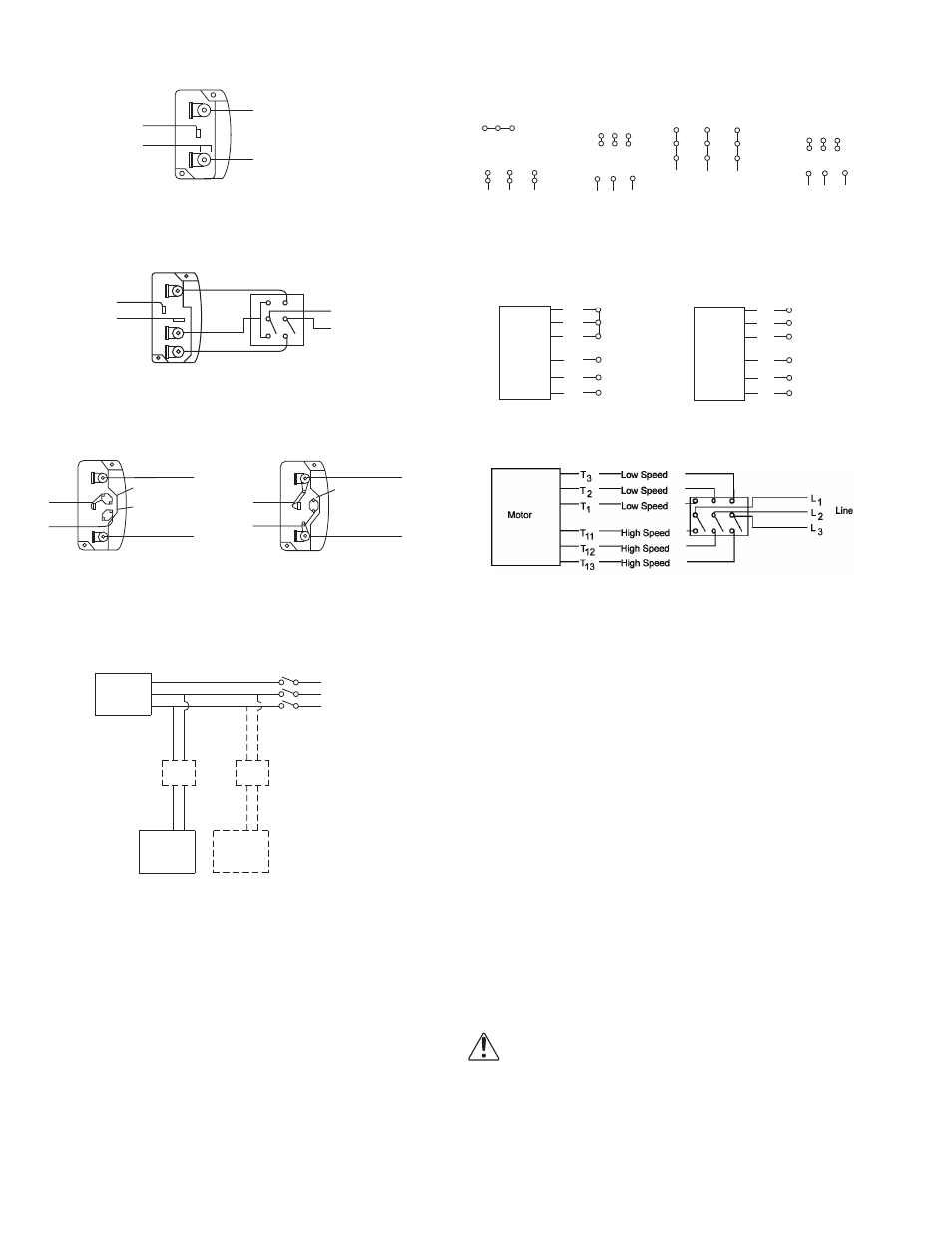

Wiring Diagrams

Wiring Diagrams

When ground is required, attach to ground A or B with no. 6 thread forming

screw. To reverse, interchange T-1 and T-4.

Single Speed, Single Phase Motor

To reverse, interchange any 2 line leads.

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4 leads.

2 Speed, 2 Winding, Single Phase Motor

2 Speed, 1 Winding, 3 Phase Motor

To reverse, interchange any 2 line leads. Motors require magnetic control.

Single Speed, Single Phase, Dual Voltage

2 Speed, 2 Winding, 3 Phase

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-5 and J-10 leads.

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2

line leads.

Typical Damper Motor Schematic

For 3 phase, damper motor voltage should be the same between L

1

and

L

2

. For single phase application, disregard L

3

. *Damper motors may be

available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. **A transformer may be pro-

vided in some installations to correct the damper motor voltage to the

specified voltage.

Installation

Motor Installation

To prevent damage to the fan during shipping, motors 5 HP

and larger, and extremely heavy motors (cast iron or

severe duty) are shipped loose and must be field mounted.

Wiring Installation

All wiring should be in accordance with local ordinances

and the National Electrical Code, NFPA 70. Ensure the

power supply (voltage, frequency, and current carrying

capacity of wires) is in accordance with the motor name-

plate. Refer to the Wiring Diagrams.

Direct drive - Wire the electrical box on the blower hous-

ing.

Leave enough slack in the wiring to allow for motor

movement when adjusting belt tension. Some fractional

motors have to be removed in order to make the connec-

tion with the terminal box at the end of the motor. To

remove motor, remove bolts securing motor base to power

assembly. Do not remove motor mounting bolts.

Follow the wiring diagram in the disconnect

switch and the wiring diagram provided with

the motor. Correctly label the circuit on the

main power box and always identify a closed

switch to promote safety (i.e., red tape over a

closed switch).

Ground A

Ground B

T-1

T-4

Low Speed

High Speed

L1

L2

Line

Ground B

J-10

T-5

Ground A

Link A

Link B

Low Voltage

Line

L 2

L 1

Ground A

Link A & B

L1

L 2

Line

Ground B

T-5

J-10

T-1

T-4

Ground B

L2

L1

Ground A

Line