Typical installations, Troubleshooting, Exhaust fan with osha wire guard & shutter – COOK Propeller Wall Fans User Manual

Page 7: Problem and potential cause

7

• Incorrect direction of rotation. Make sure the fan

rotates in same direction as the arrows on the motor

or belt drive assembly.

• Cooling air diverted or blocked.

• Improper inlet clearance.

• Incorrect fan RPMs.

• Incorrect voltage.

• Overheated Bearings

• Improper bearing lubrication

• Excessive belt tension.

Typical Installations

(Dimensions are in inches)

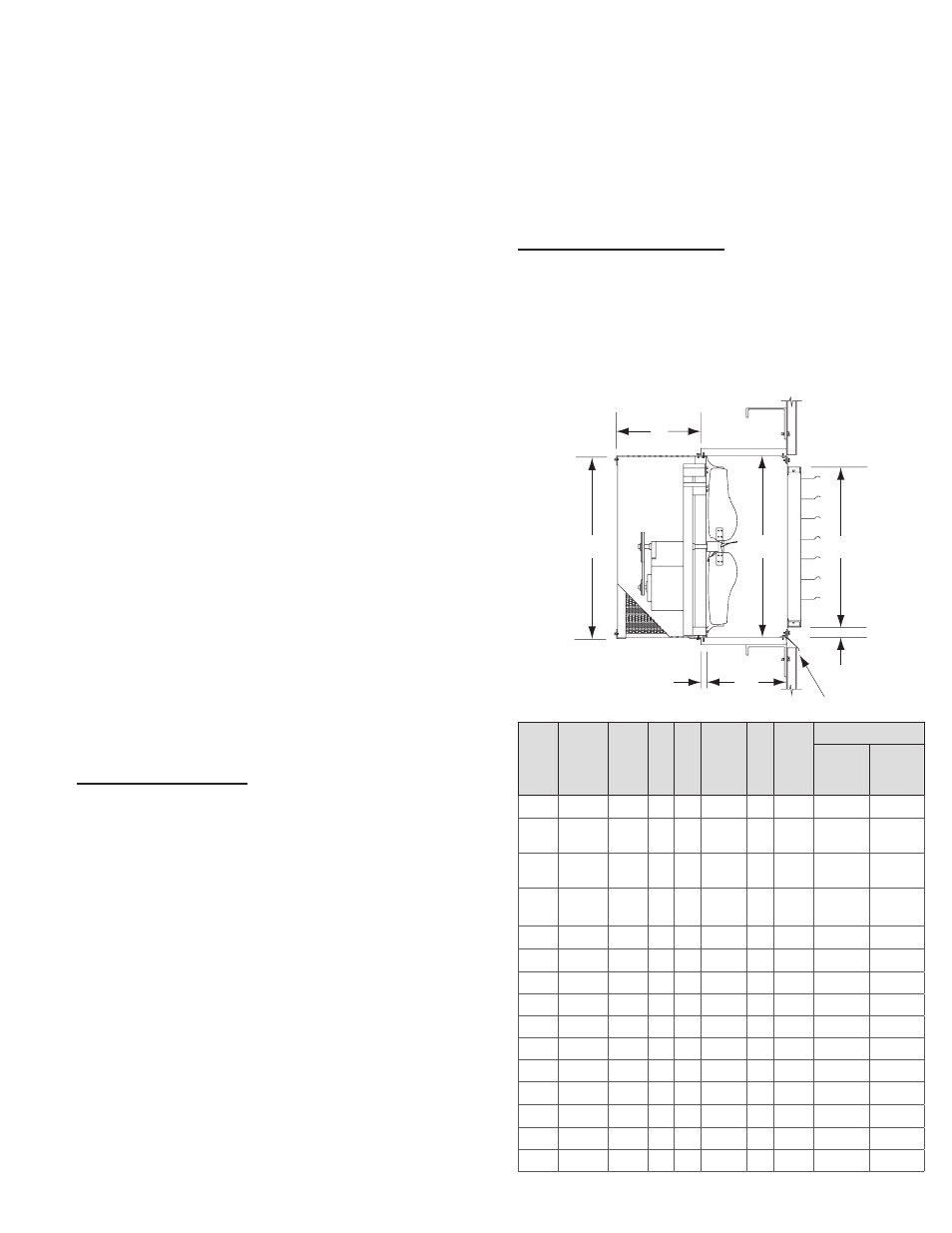

Exhaust fan with OSHA wire guard & shutter

Illustrated is the typical installation of an exhaust wall fan

with an OSHA wire guard and shutter in a steel structure

with corrugated siding. The installer will provide a sleeve

of suitable material to support the fan at a correct distance

from the shutter (minimum distance is the “A” dimension).

D

A

1-1/2

1-1/2

WO

C

B

Fan support and flashing by others.

AWB

AWD

SWD

XLW

XLWH

XMW

XMWH

EWB

EWD

A

B

C

D

E

WO

Std.

Fan

Wire

Guard.

8

-

-

11

13

12-3/4

10

1

12-1/2

13-1/4

10-

12

-

-

12

13

16-3/4

14

1

16-7/16

17-1/4

14-

16

-

-

12

13

20-3/4

18

1

20-7/16

21-1/4

18-

20

-

-

13

12

24-3/4

22

1

24-7/16

25-1/4

-

20

-

13

21

24-3/4

22

1

24-7/16

25-1/4

24

-

-

15

21

30-3/4

27

1-1/2

30-7/16

31-1/4

-

24

-

15

13

30-3/4

27

1-1/2

30-7/16

31-1/4

30

30

24

16

21

36-3/4

33

1-1/2

36-7/16

37-1/4

36

36

30

16

21

42-3/4

39

1-1/2

42-7/16

43-1/4

42

42

36

17

26

48-7/8

45

1-1/2

48-7/16

49-1/4

48

48

42

17

26

54-7/8

51

1-1/2

54-7/16

55-5/16

-

54

48

17

28

60-7/8

57

1-1/2

60-7/16

61-5/16

-

60

54

17

28

66-7/8

63

1-1/2

66-7/16

67-1/2

-

-

60

17

28

72-7/8

69

1-1/2

72-7/16

73-1/2

-

-

72

17

31

84-7/8

81

1-1/2

84-7/16

85-1/2

inner ring face with a soft driver may be required. Do

not hammer on the housing.

9. The outer ring of the bearing is spherical and

swivels in the housing to compensate for

misalignment. Slightly tighten the hold down bolts.

10. Align the setscrews on the bearings and tighten one

setscrew on each bearing.

11. Rotate the shaft to allow the bearing outer rings to

find the center of free movement.

12. Install the propeller on the shaft and adjust the

bearing position to center the propeller in the

opening.

13. Tighten the hold-down bolts to the proper torque.

Refer to the Torque Chart, page 4.

14. Turn the shaft by hand. Resistance should be the

same as it was before the hold-down bolts were fully

tightened.

15. Tighten the bearing setscrews to the specified

torque.

16. Install the pulley and adjust the belt tension.

17. After 24 hours of continuous operation, tighten the

setscrews to the appropriate torque. This assures

the full locking of the inner race to the shaft. Ensure

the socket key or driver is in good condition with no

rounded corners. The key should be fully engaged

in the setscrew and held squarely to prevent the

rounding out of the setscrew socket when applying

maximum torque.

18. Tighten the bearing setscrews to the specified

torque.

19. Install the pulley and adjust the belt tension.

20. After 24 hours of continuous operation, tighten the

setscrews to the appropriate torque. This assures

the full locking of the inner race to the shaft. Ensure

the socket key or driver is in good condition with no

rounded corners. The key should be fully engaged

in the setscrew and held squarely to prevent the

rounding out of the setscrew socket when applying

maximum torque.

Troubleshooting

Problem and Potential Cause

Low Capacity or Pressure

• Incorrect direction of rotation. Make sure the fan

rotates in same direction as the arrows on the motor

or belt drive assembly.

• Poor fan inlet conditions. There should be a straight

clear duct at the inlet.

• Improper propeller alignment.

Excessive Vibration and Noise

• Damaged or unbalanced propeller.

• Belts too loose; worn or oily belts.

• Speed too high.

• Incorrect direction of rotation. Make sure the fan

rotates in same direction as the arrows on the motor or

belt drive assembly.

• Bearings need lubrication or replacement.

• Fan surge.

Overheated Motor

• Motor improperly wired.