Pulley and belt replacement, Bearing replacement – COOK Propeller Wall Fans User Manual

Page 6

6

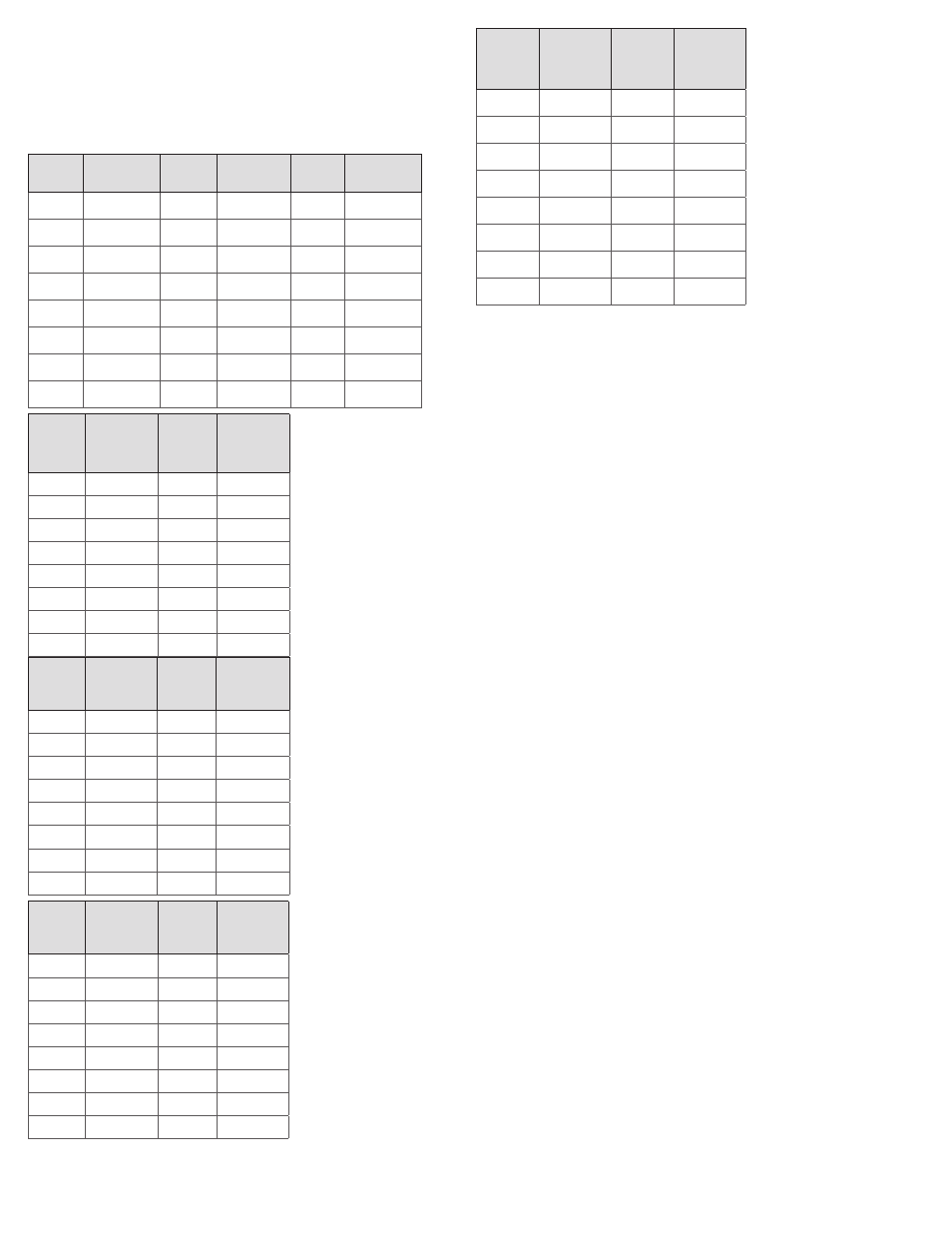

XMW/

XMWHS

Size

Maximum

RPM

XMWH/

XMWHS

Size

Maximum

RPM

20

1462

-

-

24

1272

24

1385

30

860

30

1175

36

672

36

948

42

498

42

829

48

416

48

726

54

350

54

522

60

320

60

530

Pulley and Belt Replacement

1. Clean the motor and fan shafts.

2. Loosen the motor plate mounting bolts to relieve

the belt tension. Remove the belt.

3. Loosen the pulley setscrews and remove the

pulleys from the shaft.

NOTICE! If excessive force

is required to remove the pulleys, a three-

jaw puller can be used. This tool, however,

can easily warp a pulley. If the puller is used,

inspect the trueness of the pulley after it is

removed from the shaft. The pulley will need

replacement if it is more than 0.020 inch out of

true.

4. Clean the bores of the pulleys and place a light

coat of oil on the bores.

5. Remove grease, rust and burrs from the shaft.

6. Place fan pulley on the fan shaft and the motor

pulley on the motor shaft. Damage to the pulleys

can occur when excessive force is used in placing

the pulleys on their respective shafts.

7. After the pulleys have been correctly placed back

onto their shafts, tighten the pulley setscrews.

8. Install the belts on the pulleys. Align and adjust the

belts to the proper tension as described in Belt and

Pulley Installation, page 2

Bearing Replacement

The fan bearings are pillow block ball bearings.

1. Mark the position of the shaft in reference to both

the bearing races and the propeller and pulley.

Make a note of the clearance between the propeller

and the frame.

2. Remove the pulley.

3. Remove the propeller from the shaft. A two-jaw

puller may be needed to remove the propeller from

the shaft.

4. Remove the bearing hold-down bolts. Remove the

shaft and the bearings as one unit.

5. Remove the anti-corrosion coating from the shaft

with a suitable degreaser.

6. Remove the bearing from the shaft using a bearing

puller. If a bearing puller is not available, remove

the bearing by using a wood block and hammer.

An emery cloth or file may be needed to remove

imperfections in the shaft left by the setscrews.

7. Clean the shaft and bearing bore thoroughly.

8. Place the bearings into position ensuring they are

not on a worn section of the shaft. Tapping the

Speed Increase

Close the pulley in order that the belt rides higher in the

groove (larger pitch diameter). Ensure that the RPM limits

of the fan and the horsepower limits of the motor are

maintained.

Maximum RPM

EWB

Size

Maximum

RPM

AWB

Size

Maximum

RPM

APB

Size

Maximum

RPM

24

1675

24

1510

24

1005

30

1370

30

1145

30

800

36

1310

36

990

36

645

42

1175

42

905

42

660

48

1215

48

900

48

605

54

960

-

-

-

-

60

890

-

-

-

-

72

700

-

-

-

-

XLP/

XLPS

Size

Maximum

RPM

XLPH/

XLPHS

Size

Maximum

RPM

20

1280

-

-

24

1012

24

1100

30

666

30

1074

36

566

36

895

42

424

42

870

48

356

48

761

54

316

54

472

60

260

60

446

XMP/

XMPS

Size

Maximum

RPM

XMPH/

XMPHS

Size

Maximum

RPM

20

1280

-

-

24

1276

24

1385

30

830

30

1175

36

680

36

948

42

498

42

829

48

414

48

726

54

346

54

522

60

318

60

530

XLW/

XLWS

Size

Maximum

RPM

XLWH/

XLWHS

Size

Maximum

RPM

20

1276

-

-

24

1018

24

1126

30

674

30

1074

36

570

36

895

42

422

42

870

48

356

48

761

54

320

54

478

60

256

60

438