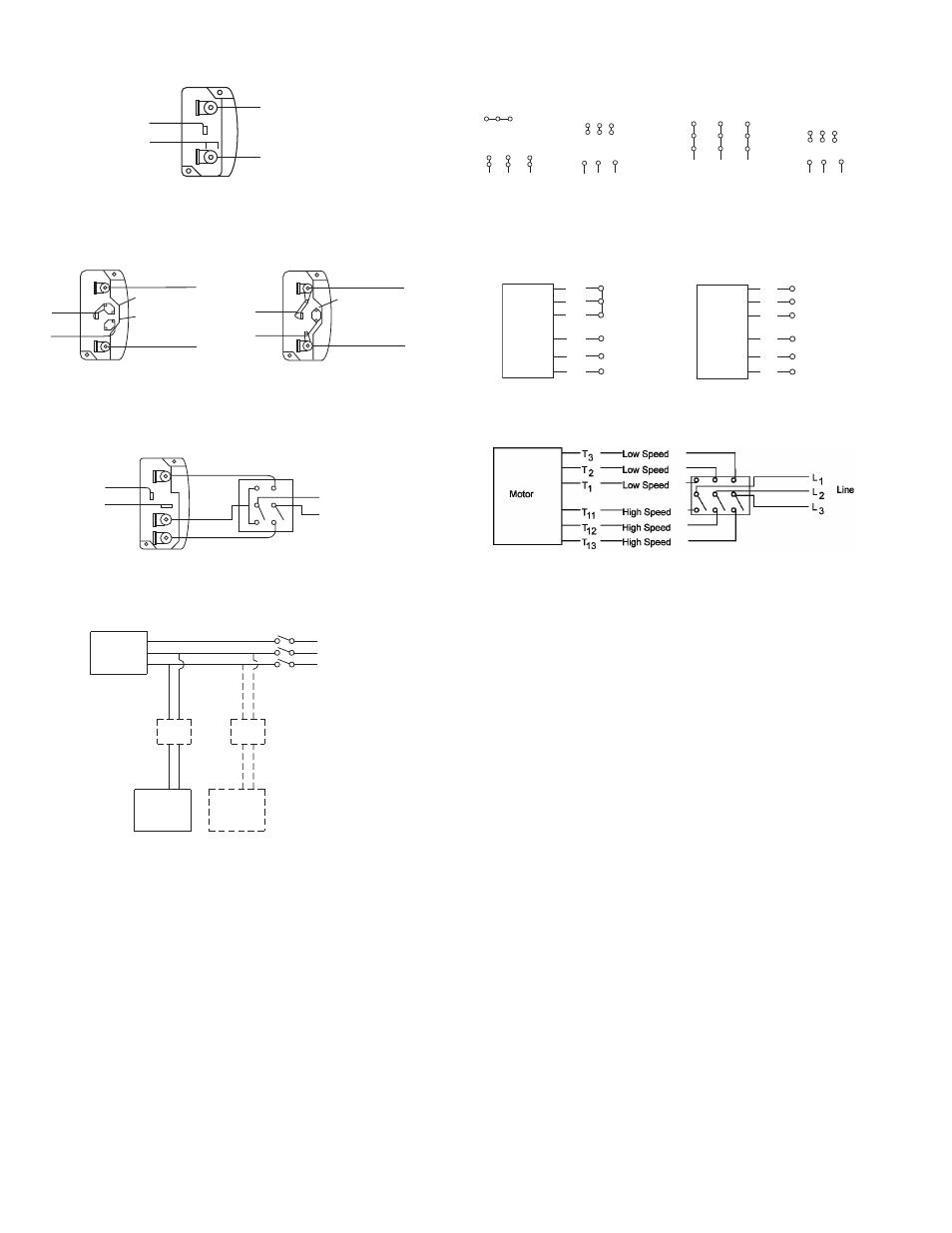

Wiring diagrams, Maintenance, Single speed, single phase motor – COOK Propeller Inline User Manual

Page 4: Typical damper motor schematic

4

T-1

T-4

Ground B

L 2

L1

Ground A

Line

Wiring Diagrams

Fan

Motor

Damper

Motor*

Second

Damper

Motor

Transformer**

Transformer**

L3

L2

L1

Wiring Diagrams

When ground is required, attach to ground A or B with no. 6 thread forming

screw. To reverse, interchange T-1 and T-4.

Single Speed, Single Phase Motor

To reverse, interchange any 2 line leads.

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4 leads.

2 Speed, 2 Winding, Single Phase Motor

2 Speed, 1 Winding, 3 Phase Motor

To reverse, interchange any 2 line leads. Motors require magnetic control.

Single Speed, Single Phase, Dual Voltage

2 Speed, 2 Winding, 3 Phase

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-5 and J-10 leads.

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2

line leads.

Typical Damper Motor Schematic

Maintenance

Establish a schedule for inspecting all parts of the

fan.The frequency of inspection depends on the operating

conditions and location of the fan.

Inspect fans exhausting corrosive or contaminated air

within the first month of operation. Fans exhausting contam-

inated air (airborne abrasives) should be inspected every

three months. Clean the propeller and air inlets if material

build-up is excessive. Excessive build-up can cause imbal-

ance and failure of the propeller. Always clean the entire

propeller as partial cleaning will cause imbalance and fan

failure.

Regular inspections are recommended for fans exhaust-

ing non-contaminated air.

It is recommended the following inspections be con-

ducted twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary.

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. See

Belt and Pulley Installation, page 1.

• Bearings should be inspected as recommended in the

Conditions Chart, page 5.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling.

For 3 phase, damper motor voltage should be the same between L

1

and

L

2

. For single phase application, disregard L

3

. *Damper motors may be

available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. ** A transformer may be pro-

vided in some installations to correct the damper motor voltage to the

specified voltage.

Ground A

Ground B

T-1

T-4

Low Speed

High Speed

L 1

L 2

Line

Ground B

J-10

T-5

Ground A

Link A

Link B

Low Voltage

Line

L 2

L 1

Ground A

Link A & B

L1

L 2

Line

Ground B

T-5

J-10

Motor

1

2

3

4

5

6

Together

High Speed

Line

L1

L2

L3

1

2

3

4

5

6

Open

Low Speed

Line

L1

L2

L3

Motor

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection