Wiring, Final steps, Operation – COOK Propeller Inline User Manual

Page 3: Inspection, Wiring installation, Final installation steps, Start up

3

Ceiling Mounted Units

a. Mount the fan to its support structure.

b. When all the installation supports have been removed

and the fan is supported only by the permanent struc-

ture, attach the duct work.

c. Drill holes through the flanges to match the duct, then

bolt the duct and flanges together.

Wiring Installation

All wiring should be in accordance with local ordinances

and the National Electrical Code, NFPA 70. Ensure the

power supply (voltage, frequency, and current carrying

capacity of wires) is in accordance with the motor name-

plate. Refer to the Wiring Diagrams, next page.

Leave enough slack in the wiring to allow for motor

movement when adjusting belt tension. Some fractional

motors have to be removed in order to make the connec-

tion with the terminal box at the end of the motor.

Follow the wiring diagram in the disconnect

switch and the wiring diagram provided with the

motor. Correctly label the circuit on the main

power box and always identify a closed switch

to promote safety (i.e., red tape over a closed

switch).

Belt Drive Fans

a. Run wire to the fan. Restrain wire to the housing or

motor plate to prevent it from being pulled into the

shaft.

b. Pull the wire into the motor. For final connections, fol-

low the wiring diagram provided on the motor.

Direct Drive Fans

a. Drill a hole through the fan housing at a convenient

location and pull the wire through it or pull the wire

through the intake duct.

b. Pull the wire into the motor wiring box. Restrain the

wire to prevent it from being pulled into the shaft.

c. For final connections, follow the wiring diagram pro-

vided on the motor.

Final Installation Steps

a. Inspect fasteners and setscrews, particularly fan

mounting and bearing fasteners, and tighten accord-

ing to the recommended torque shown in the table,

Recommended Torque for Setscrews/Bolts.

b. Inspect for correct voltage with voltmeter.

c. Ensure all accessories are installed.

d. Test the fan to be sure the rotation is the same as indi-

cated by the arrow marked Rotation.

NOTICE! Do not allow the fan to run in the wrong

direction. This will overheat the motor and cause seri-

ous damage. For 3-phase motors, if the fan is running

in the wrong direction, check the control switch. It is

possible to interchange two leads at this location so

that the fan is operating in the correct direction.

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power

sources.

b. Inspect fasteners and setscrews, particularly those

used for mounting the unit, and tighten if necessary.

c. Inspect belt tension and pulley alignment. (Remem-

ber, if belt tension is correct, a loud squeal occurs as

the fan increases to full power.)

d. Inspect motor wiring.

e. Ensure the belt touches only the pulleys.

f. Rotate the prop to ensure it does not rub against the

venturi.

g. Ensure fan and ductwork are clean and free of debris.

h. Test the fan to ensure the rotation of the propeller is

the same as indicated by the rotation label.

i. Close and secure all access doors.

j. Restore power to unit.

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed. Inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Bearing noise.

• Improper belt alignment or tension (listen for a continu-

ous squealing noise).

• Improper motor amperage or voltage.

NOTICE! If a problem is discovered, immediately

shut off the fan. Lock out all electrical power and check

for the cause of the trouble. Refer to Troubleshooting,

page 6.

Inspection

Inspection of the fan should be conducted at the first 30

minute, 8 hour and 24 hour intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as per

directions below.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension. Adjust and tighten as necessary.

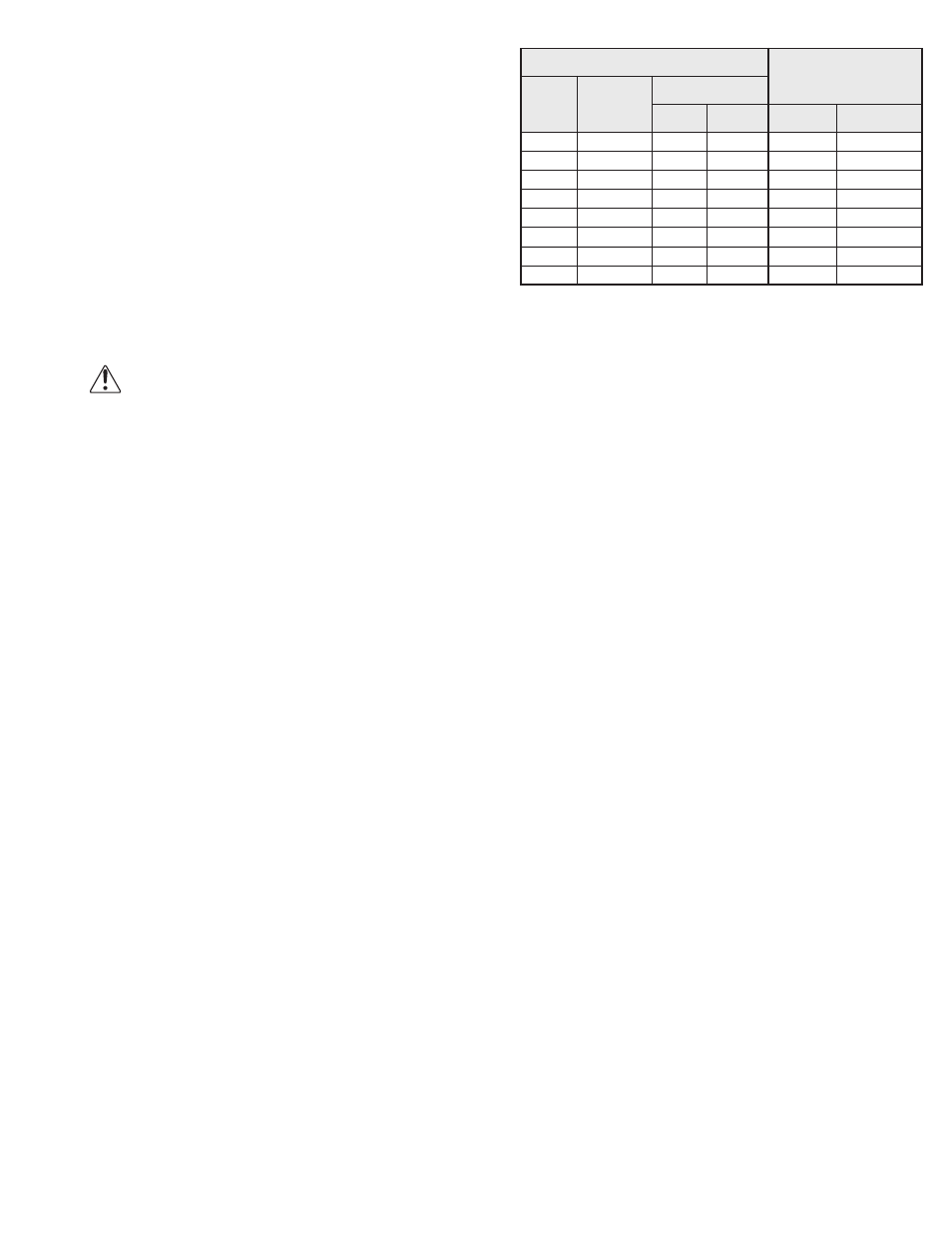

Recommended Torque for Setscrews/Bolts (IN/LB.)

Setscrews

Hold Down Bolts

Size

Key Hex

Across

Flats

Recommended

Torque

Min.

Max.

Size

Wrench

Torque

No.10

3/32”

28

33

3/8”-16

240

1/4”

1/8”

66

80

1/2”-13

600

5/16”

5/32”

126

156

5/8”-11

1200

3/8”

3/16”

228

275

3/4”-10

2100

7/16”

7/32”

348

384

7/8”-9

2040

1/2”

1/4”

504

600

1”-8

3000

5/8”

5/16”

1104

1200

1-1/8”-7

4200

3/4”

3/8”

1440

1800

1-1/4”-7

6000