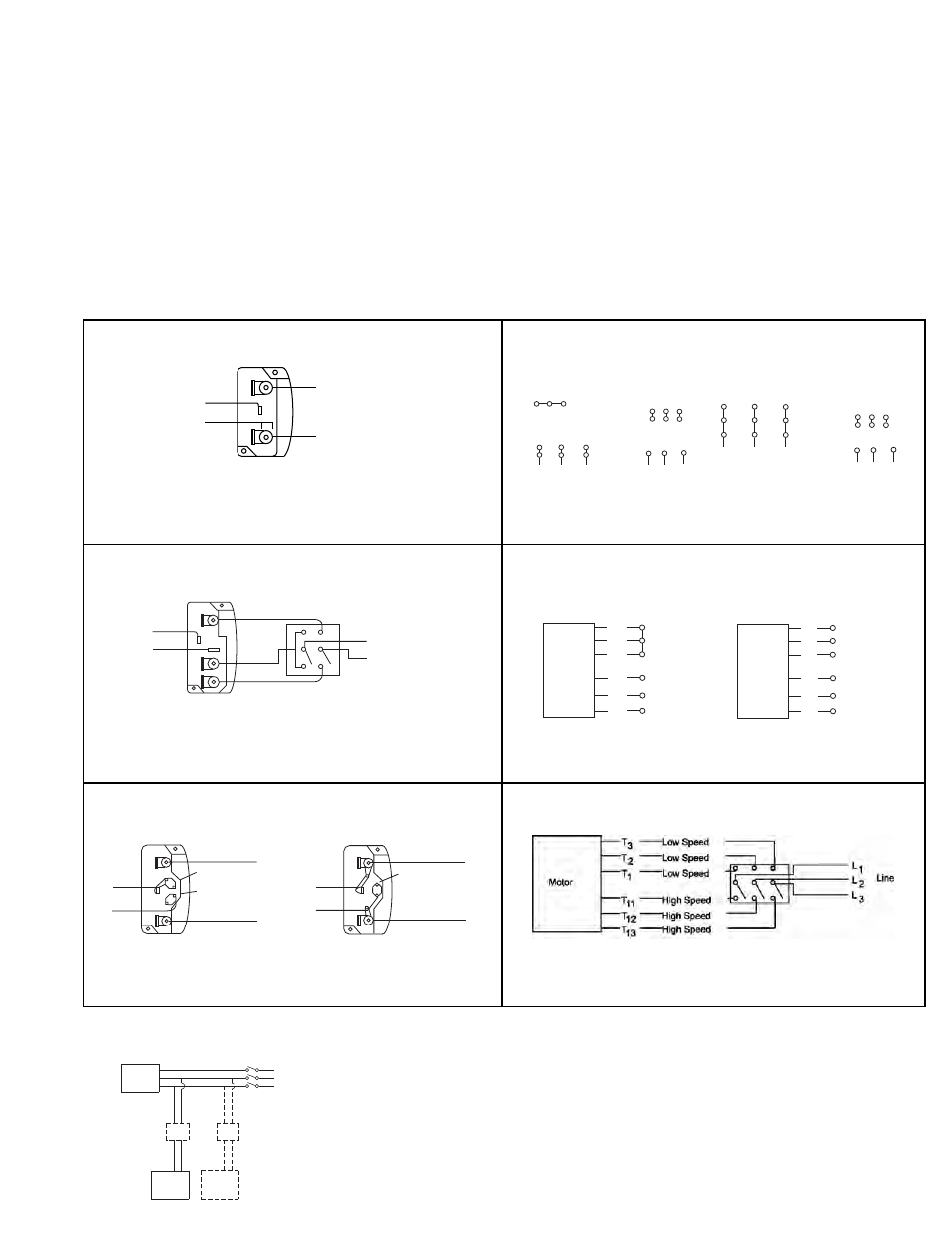

Use of variable frequency drives, Wiring diagrams, Single speed, single phase motor – COOK PLC User Manual

Page 3: 2 speed, 1 winding, 3 phase motor, 3 phase, 9 lead motor delta-connection, 3 phase, 9 lead motor y-connection, Typical damper motor schematic

3

Ground A

Ground B

T-1

T-4

Low Speed

High Speed

L 1

L 2

Line

Motor

1

2

3

4

5

6

Together

High Speed

Line

L1

L2

L3

1

2

3

4

5

6

Open

Low Speed

Line

L1

L2

L3

Motor

Wiring -

Line reactors may be required to reduce over-voltage

spikes in the motors. The motor manufacturer should be

consulted for recommended line impedence and usage of

line reactors or filters, if the lead length between the VFD

and the motor exceeds 10 feet (3m).

Fan -

It is the responsibility of the installing body to perform

coast-down tests and identify any resonant frequencies

after the equipment is fully installed. These resonant fre-

quencies are to be removed from the operating range of

the fan by using the “skip frequency” function in the VFD

programming. Failure to remove resonant frequencies

from the operating range will decrease the operating life of

the fan and void the warranty.

Use of Variable Frequency Drives

Motors -

Motors that are to be operated using a Variable Fre-

quency Drive (VFD) must be VFD compatible. At a mini-

mum, this must be a Premium Efficiency motor with Class F

insulation. Motors that are not supplied by Loren Cook

Company should have the recommendation of the motor

manufacturer for use with a VFD.

Grounding -

The fan frame, motor and VFD must be connected to a

common earth ground to prevent transient voltages from

damaging rotating elements.

Wiring Diagrams

When ground is required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4.

Single Speed, Single Phase Motor

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4 leads.

2 Speed, 2 Winding, Single Phase Motor

Single Speed, Single Phase, Dual Voltage

2 Speed, 2 Winding, 3 Phase

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-5 and J-10 leads.

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2

line leads.

2 Speed, 1 Winding, 3 Phase Motor

To reverse, interchange any 2 line leads. Motors require magnetic control.

T-1

T-4

Ground B

L 2

L1

Ground A

Line

To reverse, interchange any 2 line leads.

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

Ground B

J-10

T-5

Ground A

Link A

Link B

Low Voltage

Line

L 2

L 1

Ground A

Link A & B

L1

L 2

Line

Ground B

T-5

J-10

Fan

Motor

Damper

Motor*

Second

Damper

Motor

Transformer**

Transformer**

L3

L2

L1

Typical Damper Motor Schematic

For 3 phase, damper motor voltage should be the same between L

1

and L

2

. For single phase application, dis-

regard L

3

. *Damper motors may be available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. **A transformer may be provided in some installations to correct

the damper motor voltage to the specified voltage.