Isolators, Duct installation, Wheel-to-inlet clearance – COOK PLC User Manual

Page 2: Wiring installation

2

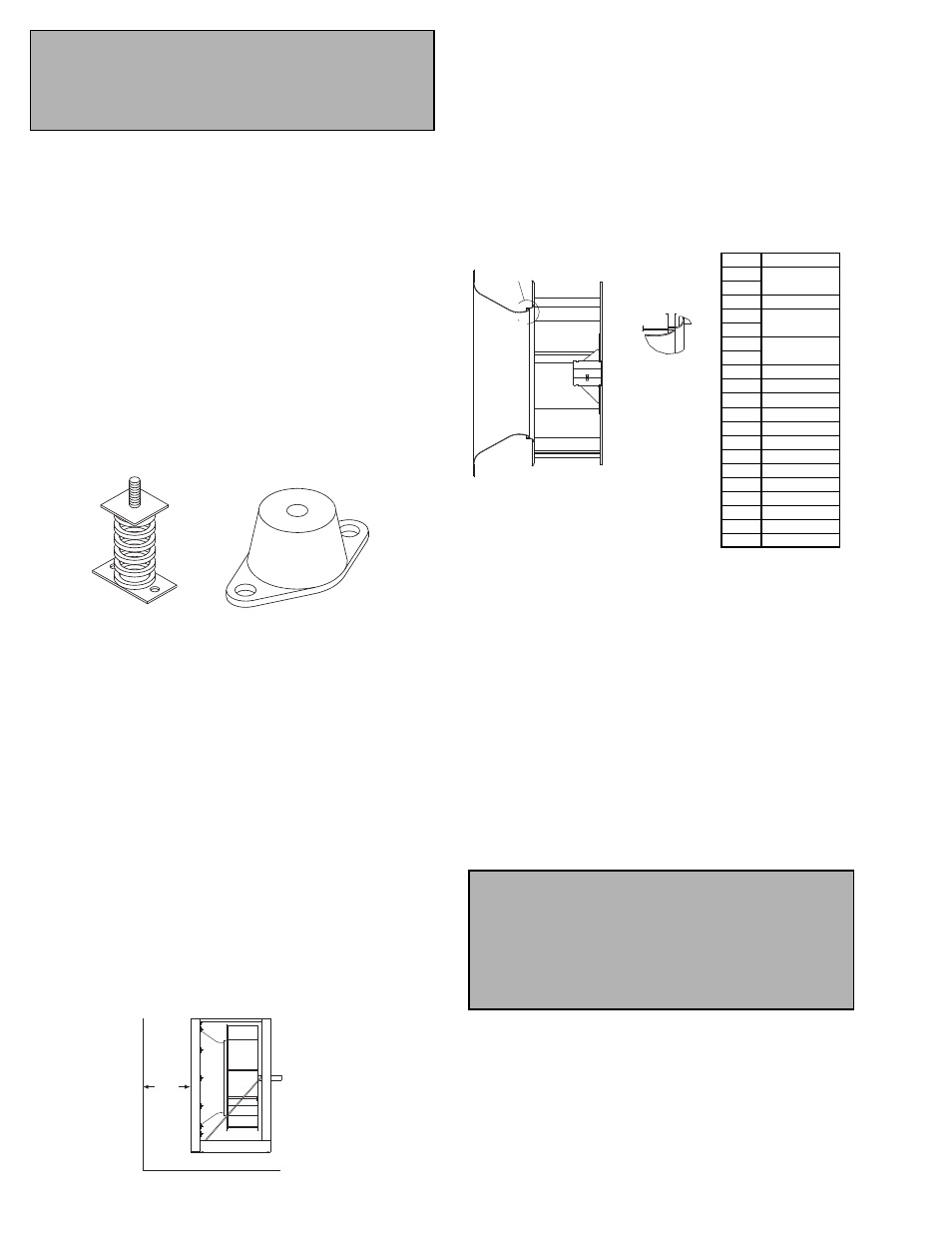

Wheel-to-Inlet Clearance

The correct wheel-to-inlet clearance is critical to proper

fan performance. This clearance should be verified before

initial start-up since rough handling during shipment could

cause a shift in fan components. Refer to wheel/inlet draw-

ing for correct overlap.

Adjust the overlap by loosening the wheel hub and mov-

ing the wheel along the shaft to obtain the correct value.

A uniform radial gap (space between the edge of the

cone and the edge of the inlet) is obtained by loosening the

inlet cone bolts and repositioning the inlet cone.

Wheel/Inlet Overlap

Size

Overlap

120

.250

135

150

.313

165

.375

180

195

.438

210

225

.500

245

.563

270

.625

300

.688

330

.625

365

.688

402

.750

445

.875

490

.938

540

1.063

600

1.108

660

1.313

730

1.438

See Detail A

Overlap

Radial Gap

Detail A

Scale 2.000

Isolators

Floor Mounted Spring Isolators

• Mount fan and motor on an isolation base (if supplied).

• Elevate fan (or isolation base) to operating height and

insert blocks to hold in position.

• Position isolators under the fan and/or isolation base

and vertically align by inserting leveling bolt through

mounting holes in the fan or the base. The isolator

must be installed on a level surface.

• Adjust the isolators by turning the leveling nut counter

clockwise several turns at a time alternately on each

isolator until the fan weight is transferred onto the isola-

tors and the fan raises uniformly off the blocks. Then

remove the blocks.

• Turn lock nut onto leveling bolt and secure firmly in

place against the top of the mounting flange or frame.

• Secure isolators to mounting surface.

Floor Mounted Rubber-In-Shear (RIS) Isolators

• Mount fan and motor on an isolation base (if supplied).

• Elevate fan to provide room to insert isolators between

base and foundation or between the fan and foundation

and block in position.

• Position isolators under isolation base or fan and

secure bolts.

• Remove blocks and allow unit to rest on floor. Isolators

must be installed on a level surface (leveling should not

be required).

• Secure isolators to mounting surface.

Duct Installation

Efficient fan performance relies on proper installation.

If the fan has an open inlet (no duct work), be sure it is

placed one fan wheel diameter away from walls and bulk-

heads. Refer to figure 2.

Refer to the PLC catalog for discharge wall proximity

factors.

Note

Although a certain amount of vibration is inherent in

operating centrifugal fans, extreme vibration is a seri-

ous problem that may cause structural and mechani-

cal failure.

Rubber-In-Shear Isolator

Spring Isolator

Figure 1 - Floor Mount Isolators

Minimum

1 wheel

diameter

Figure 2 - Non-ducted Inlet Clearance

Wiring Installation

All wiring should be in accordance with local ordi-

nances and the National Electrical Code, NFPA 70.

Ensure the power supply (voltage, frequency, and cur-

rent carrying capacity of wires) is in accordance with

the motor nameplate.

Lock off all power sources before unit is wired to

power source.

Leave enough slack in the wiring to allow for motor

movement when adjusting belt tension. Some frac-

tional motors have to be removed in order to make the

connection with the terminal box at the end of the

motor. To remove motor, remove bolts securing motor

base to power assembly. Do not remove motor mount-

ing bolts.

Personal Safety

Disconnect switches are recommended. Place

the disconnect switch near the fan in order that

the power can be swiftly cut off in case of an

emergency, and in order that maintenance

personnel are provided complete control of the

power source.