Fan installation, Operation, Start up – COOK Lo-Pro User Manual

Page 4: Inspection, Maintenance, Fan bearings, Motor bearings

4

wrong direction, check the control switch. If is possible

to interchange two leads at this location so that the fan

is operating in the correct direction.

Fan Installation

Place fan over roof opening. Secure the fan with lag

screws, anchor bolts, or other suitable fasteners.

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power sources.

b. Inspect fasteners and setscrews, particularly those

used for mounting the fan, and tighten if necessary.

c. Inspect belt tension and pulley alignment. (Remember,

if belt tension is correct, a loud squeal occurs as the

fan increases to full power.)

d. Inspect motor wiring.

e. Ensure the belt touches only the pulleys.

f. Ensure fan and ductwork are clean and free of debris.

g. Test the fan to ensure the rotation of the wheel is the

same as indicated by the rotation label.

h. Close and secure all access doors.

i. Restore power to unit.

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed. Inspect for the following:

• Direction of rotation

• Excessive vibration

• Unusual noise

• Bearing noise

• Improper belt alignment or tension (listen for a continu-

ous squealing noise)

• Improper motor amperage or voltage

NOTICE! If a problem is discovered, immediately shut

off the fan. Lock out all electrical power and check for

the cause of the trouble. Refer to Troubleshooting,

page 6.

Inspection

Inspection of the fan should be conducted at the first 30

minute, 8 hour and 24 hour intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as per

the chart below.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension. Adjust and tighten as necessary.

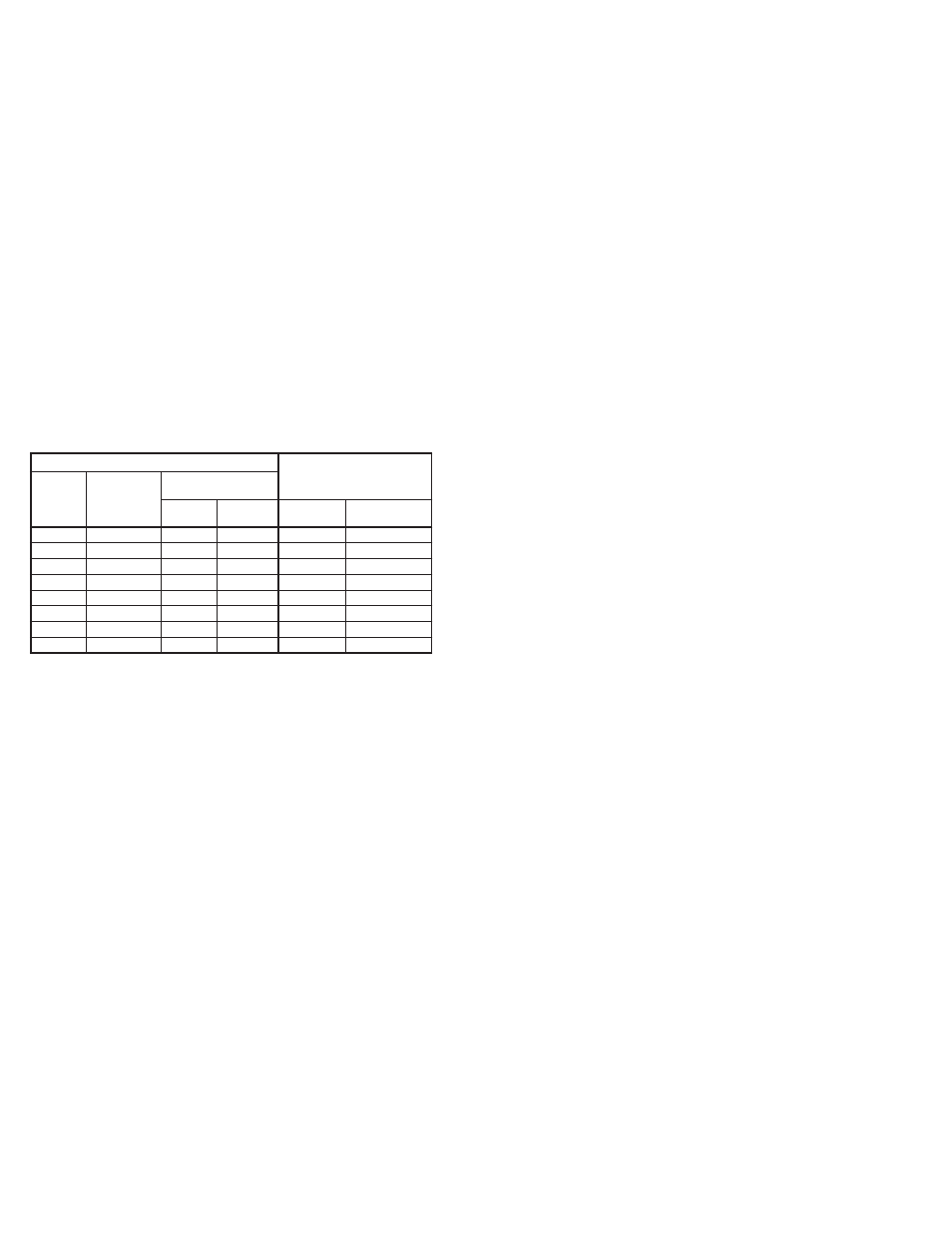

Recommended Torque for Setscrews/Bolts (IN/LB.)

Setscrews

Hold Down Bolts

Size

Key Hex

Across

Flats

Recommended

Torque

Min.

Max.

Size

Wrench

Torque

No.10

3/32”

28

33

3/8”-16

240

1/4”

1/8”

66

80

1/2”-13

600

5/16”

5/32”

126

156

5/8”-11

1200

3/8”

3/16”

228

275

3/4”-10

2100

7/16”

7/32”

348

384

7/8”-9

2040

1/2”

1/4”

504

600

1”-8

3000

5/8”

5/16”

1104

1200

1-1/8”-7

4200

3/4”

3/8”

1440

1800

1-1/4”-7

6000

Maintenance

Establish a schedule for inspecting all parts of the

fan.The frequency of inspection depends on the operating

conditions and location of the fan.

Inspect fans exhausting corrosive or contaminated air

within the first month of operation. Fans exhausting con-

taminated air (airborne abrasives) should be inspected

every three months. Clean the wheel and air inlets if mate-

rial build-up is excessive. Excessive build-up can cause

imbalance and failure of the wheel.

Regular inspections are recommended for fans exhaust-

ing non-contaminated air.

Regular inspections of the Grease Terminator 2 are rec-

ommended. Depending on the amount of grease dis-

charged through the fan, the Terminator 2 should be

changed every 30 to 45 days to ensure proper operation.

Any buildup of grease is easily seen during a visual inspec-

tion of the clear canister. However, if the Terminator 2

becomes saturated, grease will no longer be absorbed.

It is recommended the following inspections be con-

ducted twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary.

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. See

Belt and Pulley Installation, page 2.

• Bearings should be inspected as recommended in the

Conditions Chart, page 5.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling.

Fan Bearings

The fan bearings are provided prelubricated. Any spe-

cialized lubrication instructions on fan labels supercedes

information provided herein. Bearing grease is a petroleum

lubricant in a lithium base conforming to a NLGI #2 consis-

tency. If user desires to utilize another type of lubricant,

they take responsibility for flushing bearings and lines, and

maintaining a lubricant that is compatible with the installa-

tion.

A NLGI #2 grease is a light viscosity, low-torque, rust-

inhibiting lubricant that is water resistant. Its temperature

range is from -30°F to 200°F and capable of intermittent

highs of 250°F.

Bearings should be relubricated in accordance with the

condition chart below.

For best results, lubricate the bearing while the fan is in

operation. Pump grease in slowly until a slight bead forms

around the bearing seals. Excessive grease can damage

seal and reduce life through excess contamination and/or

loss of lubricant.

In the event that the bearing cannot be seen, use no

more than three injections with a hand operated grease

gun.

Motor Bearings

Motors are provided with prelubricated bearings. Any

lubrication instructions shown on the motor nameplate

supersede instructions below.