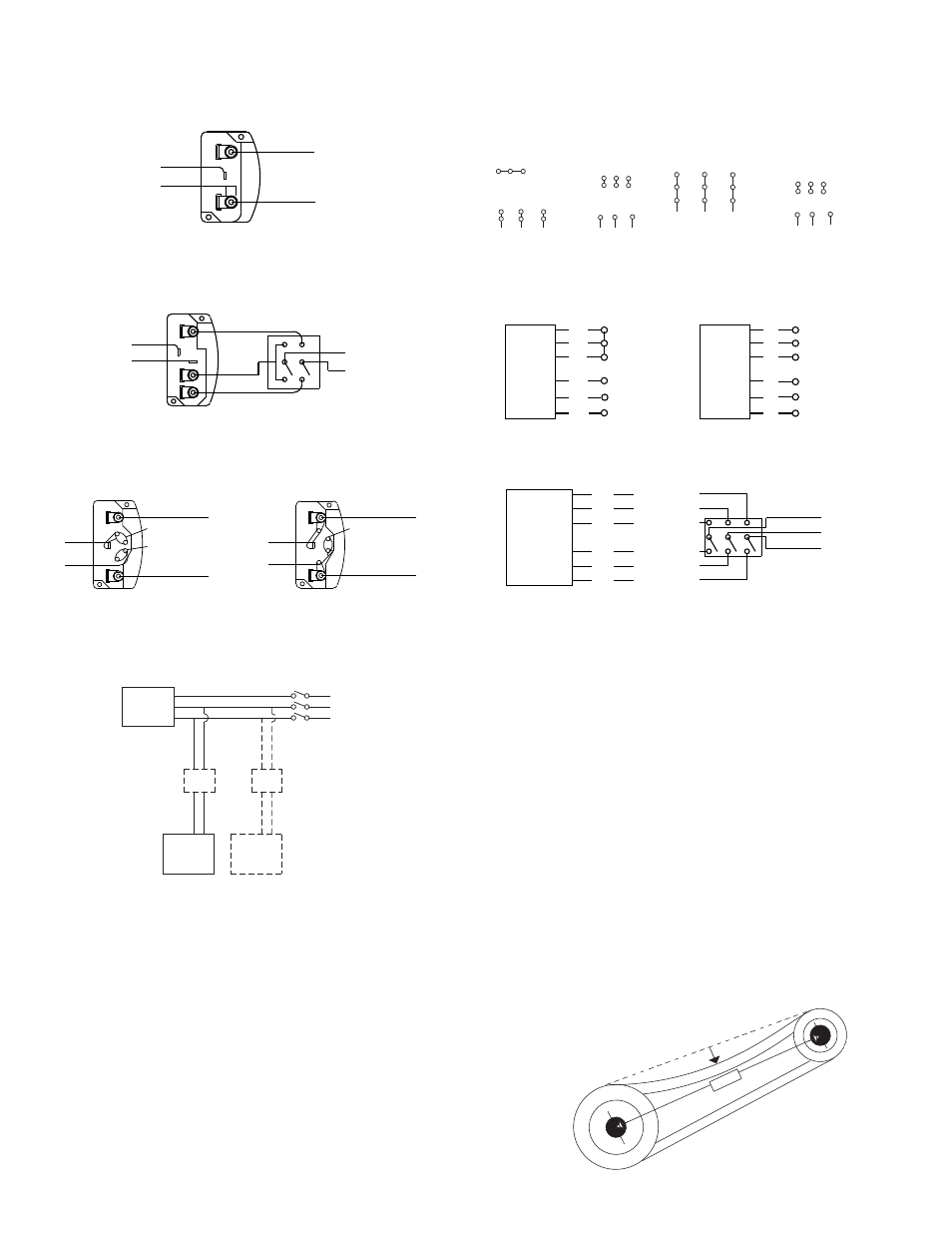

Belt and pulley, Belt and pulley installation, Wiring diagrams – COOK Duct Blower User Manual

Page 2: Single speed, single phase motor, Typical damper motor schematic

2

1 foot

1/4 inch

For proper tension, a deflection of approximately 1/4”

per foot of center distance should be obtained by

firmly pressing the belt. Refer to Figure 1.

c. Lock the motor plate adjustment nuts in place.

d. Ensure pulleys are properly aligned. Refer to Figure 2.

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection

Figure 1

Fan

Motor

Damper

Motor*

Second

Damper

Motor

Transformer**

Transformer**

L3

L2

L1

Belt and Pulley Installation

Belt tension is determined by the sound of the belts when

the fan is first started. The belts will produce a loud squeal,

which dissipates after the fan is operating at full capacity. If

belt tension is too tight or too loose, lost efficiency and

damage can occur.

Do not change the pulley pitch diameter to change ten-

sion. The change will result in a different fan speed.

Models SDB

a. Loosen the motor plate bolts and move the motor

plate (with motor installed) so that the belts can easily

slip into the grooves on the pulleys. Never pry, roll, or

force the belts over the rim of the pulley.

b. Adjust the motor plate until proper tension is reached.

Wiring Diagrams

Wiring Diagrams

When ground is required, attach to ground A or B with no. 6 thread forming

screw. To reverse, interchange T-1 and T-4.

Ground A

L

1

L

2

Line

T-1

T-4

Ground B

Single Speed, Single Phase Motor

To reverse, interchange any 2 line leads.

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4 leads.

T-1

T-4

Ground B

Ground A

High Speed

Low Speed

L

1

L

2

Line

2 Speed, 2 Winding, Single Phase Motor

2 Speed, 1 Winding, 3 Phase Motor

To reverse, interchange any 2 line leads. Motors require magnetic control.

Together

Open

Low Speed

High Speed

Motor

Motor

1

2

3

4

5

6

L

1

L

2

L

3

L

1

L

2

L

3

1

2

3

4

5

6

Single Speed, Single Phase, Dual Voltage

2 Speed, 2 Winding, 3 Phase

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-5 and J-10 leads.

Link A

Low Voltage

Ground A

Ground B

T-5

J-10

L

1

L

2

Line

T-5

J-10

Ground A

Ground B

Link A & B

High Voltage

L

1

L

2

Line

Link B

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2

line leads.

T

3

T

2

T

1

T

11

T

12

T

13

Low Speed

Low Speed

Low Speed

High Speed

High Speed

High Speed

L

1

L

2

L

3

Motor

Typical Damper Motor Schematic

For 3 phase, damper motor voltage should be the same between L

1

and

L

2

. For single phase application, disregard L

3

. *Damper motors may be

available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. ** A transformer may be pro-

vided in some installations to correct the damper motor voltage to the

specified voltage.

Line

Line

Line

Follow the wiring diagram in the disconnect switch and the wiring diagram provided with the motor. Correctly label the circuit

on the main power box and always identify a closed switch to promote safety (i.e., red tape over a closed switch).