Bearings, Services, Shaft speed – COOK AC User Manual

Page 4: Fan bearings, Motor bearings, Motor services, Changing shaft speed, Maximum rpm with standard or reenforced wheel

4

Fan Bearings

NOTICE! The fan bearings are provided

prelubricated. Any specialized lubrication instructions

on fan labels supersedes information provided herein.

Bearing grease is a petroleum lubricant in a lithium

base conforming to a NLGI #2 consistency. If user

desires to utilize another type of lubricant, they take

responsibility for flushing bearings and lines, and

maintaining a lubricant that is compatible with the

installation.

A NLGI #2 grease is a light viscosity, low-torque, rust-

inhibiting lubricant that is water resistant. Its temperature

range is from -30°F to 200°F and capable of intermittent

highs of 250°F.

Bearings should be relubricated in accordance with the

condition chart below.

For best results, lubricate the bearing while the fan is in

operation. Pump grease in slowly until a slight bead forms

around the bearing seals. Excessive grease can damage

seal and reduce life through excess contamination and/or

loss of lubricant.

In the event that the bearing cannot be seen, use no

more than three injections with a hand operated grease

gun.

Motor Bearings

Motors are provided with prelubricated bearings. Any

lubrication instructions shown on the motor nameplate

supersede instructions below.

Direct Drive 1050/1075,1200,1300 &1500 rpm units use a

prelubricated sleeve bearing that has a oil saturated

wicking material surrounding it. The initial factory lubrication

is adequate for up to 10 years of operation under normal

conditions. However, it is advisable to add lubricant after 3

years. Use only LIGHT grade mineral oil or SAE 10W oil up

to 30 drops. If the unit has been stored for a year or more it

is advisable to lubricate as directed above. For units in

severe conditions, lubrication intervals should be reduced

to half.

Motors without sleeve bearings (as described above) will

have grease lubricated ball or roller bearings. Motor

bearings without provisions for relubrication will operate up

to 10 years under normal conditions with no maintenance.

In severe applications, high temperatures or excessive

contaminates, it is advisable to have the maintenance

department disassemble and lubricate the bearings after 3

years of operation to prevent interruption of service.

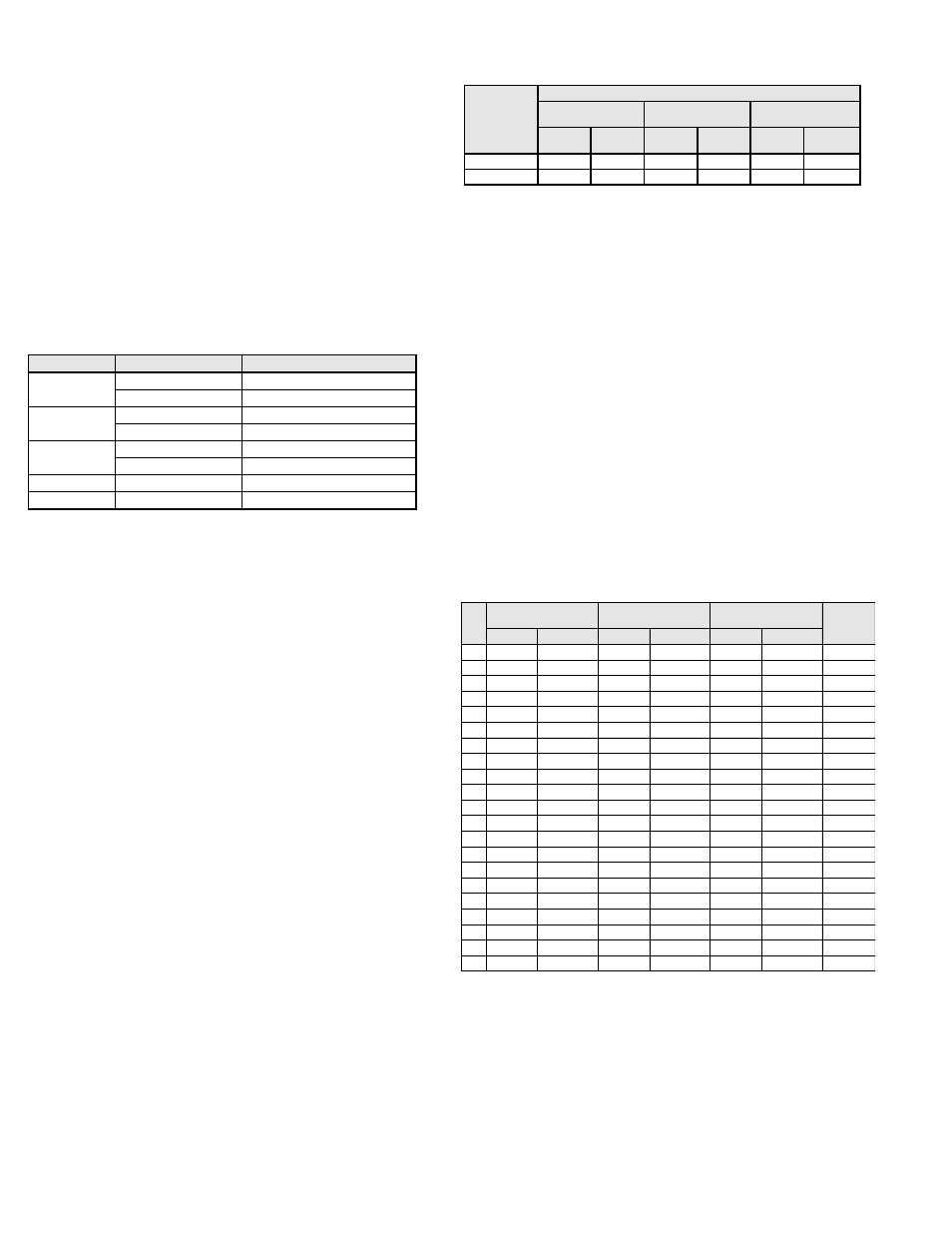

Conditions Chart

For moist or otherwise contaminated installations; divide the interval by a

factor of 3. For vertical shaft installations divide the interval by a factor of 2.

RPM

Temp °F

Greasing Interval

Up to 1000

-30 to 120

6 months

120 to 200

2 months

1000 to 3000

-30 to 120

3 months

120 to 200

1 month

Over 3000

-30 to 120

1 month

120 to 200

2 weeks

Any Speed

< -30

Consult Factory

Any Speed

> 200

1 week

For motors with provisions for relubrication, follow

intervals of the table below.

NOTICE! Motors are provided with a polyurea mineral

oil NGLI #2 grease. All additions to the motor bearings

are to be with a compatible grease such as Exxon Mobil

Polyrex EM and Chevron SRI.

The above intervals should be reduced to half for vertical

shaft installations.

Motor Services

Should the motor prove defective within a one-year period,

contact your local Loren Cook representative or your nearest

authorized electric motor service representative.

Changing Shaft Speed

All belt driven ventilators (5HP or less) are equipped with

variable pitch pulleys. To change fan speed, perform the

following:

1. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

2. Turn the pulley rim to open or close the groove facing. If

the pulley has multiple grooves, all must be adjusted to

the same width.

3. After adjustment, inspect for proper belt tension.

Speed Reduction:

Open the pulley in order that the belt rides deeper in the

groove (smaller pitch diameter).

Speed Increase:

Close the pulley in order that the belt rides higher in the

groove (larger pitch diameter). Ensure that the RPM limits of

the fan and the horsepower limits of the motor are

maintained.

Relubrication Intervals

Service

Conditions

NEMA Frame Size

Up to and

including 184T

213T-365T

404T and larger

1800 RPM

and less

Over 1800

RPM

1800 RPM

and less

Over 1800

RPM

1800 RPM

and less

Over 1800

RPM

Standard

3 yrs.

6 months

2 yrs.

6 months

1 yr.

3 months

Severe

1 yr.

3 months

1 yr.

3 months 6 months 1 months

Maximum RPM with standard or reenforced wheel

Size

ACE-B

ACRU-B &

ACW-B

ACRU-HP &

ACW-HP

ACRU-XP

&

ACW-XP

Standard Reinforced Standard Reinforced Standard Reinforced

60

1981

-

70

1941

-

80

1806

-

100

2013

-

2002

-

120

1669

-

1671

-

135

1574

-

1574

-

150

1519

-

1520

-

1952

-

165

1296

-

1295

-

1728

-

2508

180

1513

-

1546

-

1829

-

2396

195

1348

-

1353

-

1570

-

2100

210

1190

-

1197

-

1626

-

2126

225

1043

-

1086

-

1435

-

1879

245

885

-

901

-

1185

1234

1616

270

752

-

766

-

1025

1049

1656

300

837

861

837

877

980

1046

1391

330

716

734

716

748

830

912

1182

365

624

648

624

659

735

872

1132

402

539

550

539

560

445

463

465

463

473

490

360

396

360

403

540

347

401

-