Wall exhauster, Damper, Wiring – COOK AC User Manual

Page 2: Wall exhauster installation, Damper installation, Wiring installation

2

Wall Exhauster Installation

If your fan is a wall exhauster, a mounting template is

shipped with the fan. Use the template to locate the

necessary lag screws or anchor bolts on the wall. The fan

can then be lifted and attached easily. Secure with lag

screws, anchor bolts, or other suitable fasteners.

Damper Installation

If your fan is supplied with dampers, follow the directions

below. If your fan does not include dampers, proceed to

Belt and Pulley Installation.

1. Place the damper inside the curb or inside the duct

work. Ensure the damper will open freely for the correct

direction of the airflow.

2. Secure to curb at the damper shelf.

3. Drill hole in the curb shelf for conduit needed for motor

wiring.

4. Operate the dampers manually to ensure the blades

move freely.

5. Install fan over curb while aligning the conduit location

with the conduit hole in the curb.

Wiring Installation

NOTICE! All wiring should be in accordance

with local ordinances and the National Electrical

Code, NFPA 70. Ensure the power supply

(voltage, frequency, and current carrying

capacity of wires) is in accordance with the

motor nameplate.

(See page 3 for diagram)

Upblast units have two wiring conduits. The vertical

conduit comes plugged. The horizontal conduit is directly

above the vertical conduit

For Units Without A Junction Box:

An approved metal field wiring compartment must be

secured to the unit with two screws in order that the box

does not rotate. All wires must be protected from abrasion

where they enter and exit the wiring compartment. The

green ground wire from the motor must be secured under

the green ground screws inside the field wiring compartment

using a closed loop connector. Complete connections in

accordance with the wiring diagram on the motor.

For Units With A Junction Box:

Pull wires through the appropriate conduit. Protect wires

from abrasion where they enter the field wiring compartment

and complete connections in accordance with the diagram

on the motor.

Leave enough slack in the wiring to allow for motor

movement when adjusting belt tension. Some fractional

motors have to be removed in order to make the connection

with the terminal box at the end of the motor.

NOTICE! Follow the wiring diagram in the disconnect

switch and the wiring diagram provided with the motor.

Correctly label the circuit on the main power box and

always identify a closed switch to promote safety (i.e.,

red tape over a closed switch).

1. Remove the top cap which covers the motor assembly

by unlatching the snap clips.

2. For internal wiring, run the electrical wire and conduit

through the opening drilled in the damper shelf (refer to

Damper Installation), then through the wiring conduit in

the ventilator base to the motor compartment. For

external wiring, run the wires through the horizontal

conduit on upblast units, or under top cap in downblast

units.

3. Pull the wires through and complete the wiring.

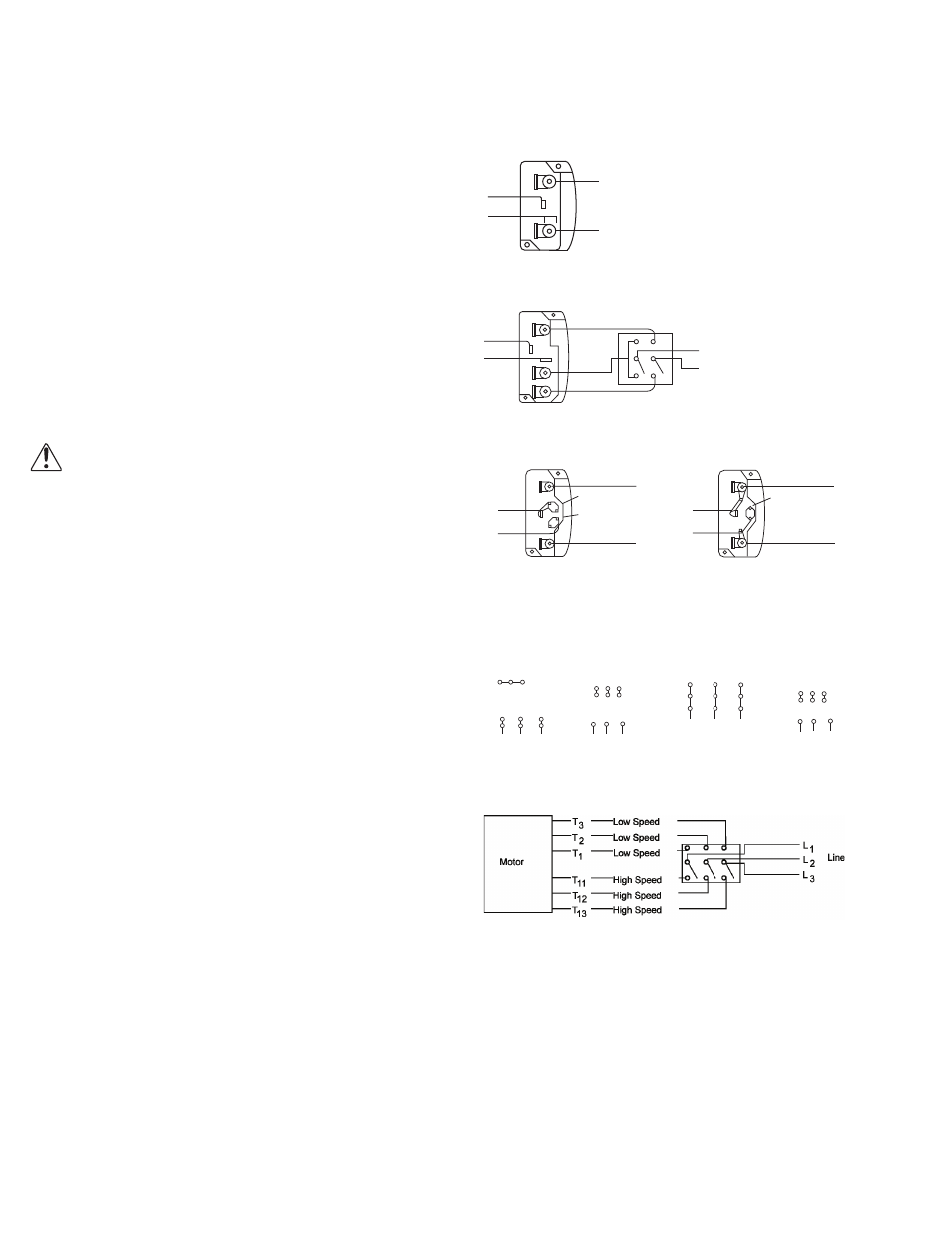

Single Speed, Single Phase Motor

2 Speed, 2 Winding, Single Phase Motor

Single Speed, Single Phase, Dual Voltage

When ground required, attach to ground A or B with No. 6 thread forming screw. To

reverse, interchange T-5 and J-10 leads.

To reverse, interchange any 2 line leads.

2 Speed, 2 Winding, 3 Phase

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2 line leads.

T-1

T-4

Ground B

L 2

L1

Ground A

Line

When ground required,

attach to ground A or B

with No. 6 thread forming

screw. To reverse, inter-

change T-1 and T-4

leads.

Ground A

Ground B

T-1

T-4

Low Speed

High Speed

L 1

L 2

Line

Ground B

J-10

T-5

Ground A

Link A

Link B

Low Voltage

Line

L 2

L 1

Ground A

Link A & B

L1

L 2

Line

Ground B

T-5

J-10

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection

When ground is required, attach to ground A or

B with no. 6 thread forming screw. To reverse,

interchange T-1 and T-4.