Swiftech MCW462TEC INTEL User Manual

Page 2

Copyright Swiftech 2001 – All rights reserved – Last revision date: Feb 1, 2002

Rouchon Industries, Inc., dbA Swiftech – 1703 E. 28

th

Street, Signal Hill, CA 90806 – Tel. 562-595-8009 – Fax 562-595-8769

E Mail: Swiftech @swiftnets.com – URL:

http://www.swiftnets.com

Information subject to change without notice

Page 2

•

To further prevent condensation to occur behind the motherboard, a neoprene sticker is provided with your water-block accessories.

Apply it to the back of the motherboard, behind the processor.

•

Re-install the MB inside the case.

II. Water-block installation

•

IMPORTANT WARNING: the solder joints to

the wires of the thermoelectric module are

extremely fragile. Bending the wires at their

root will systematically break the solder joint,

and the thermoelectric module cannot be

repaired. For this reason, we route the wires

inside the holes of the brackets that are

normally used to mount socket 423 or Xeon

processors. If you need to use these mounting

holes for your Xeon or socket 423 Pentium 4,

you should first disassemble the brackets, very

carefully re-route the wires in the socket 478

mounting holes, then re-install the brackets.

Swiftech will not honor the warranty for broken

wires.

•

It is preferable to insert the tubing into your

MCW478-UT water-block prior to installing it

onto the CPU. The reason is that inserting the

tubes into the fittings requires some strength,

and it is preferable not to do this while the block

is sitting on the CPU. If you are going to use

soft vinyl tubing (transparent tubing), it is

IMPERATIVE that you use the two plastic

inserts provided with your kit.

•

Orientation of the block is important for

bleeding purposes. Please look-up the

critical bleeding instructions paragraph on

page 3 prior to installing the block onto the

CPU.

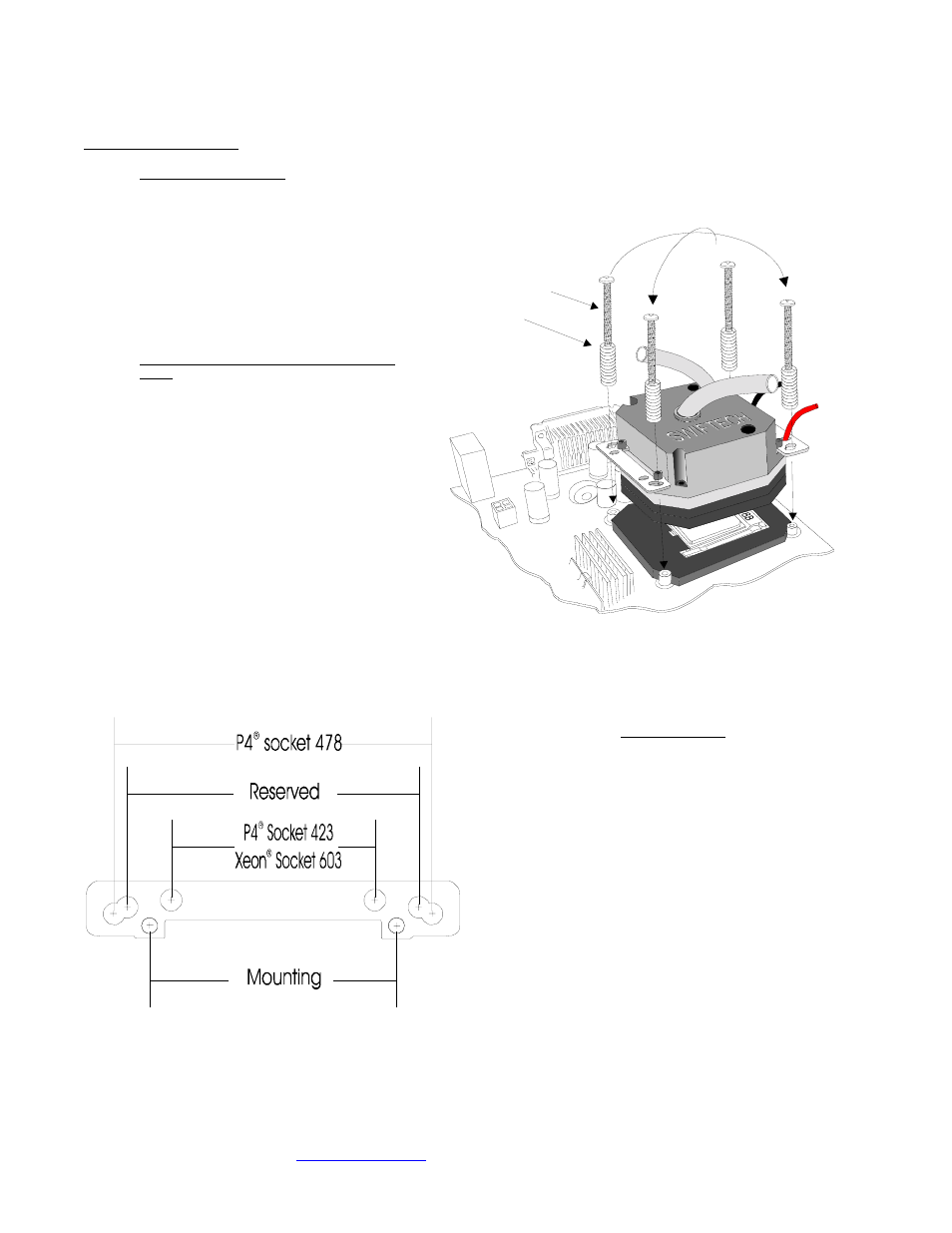

2“ screw

Spring

Crisscros

tightening

pattern

Figure 3

•

Identify the mounting holes on the bracket for your

particular processor, as shown in the schematic

below:

2"

2"

2"

2"

Install the water-bl;ock assembly onto your processor, as shown

on figure 3. Gradually tighten the screws in a crisscross pattern

until you feel that they reach the bottom of the standoff. A “finger-

tight” lock is sufficient. Over tightening may result in stripping the

nylon hex nut. Conversely, adjustments such as tightening the

screws only partially are strictly prohibited. Such attempts will result

in improper contact between the CPU core and the heat sink, and

result in CPU overheating.

Due to wide variations in gasket thickness tolerances, we

suggest that you uninstall the water-block once, following the

initial assembly just to verify that you have good contact

between the cold plate and the CPU. Inspect the grease imprint

that the CPU left on the copper plate: it should be perfectly

even!