Swiftech MCW462TEC User Manual

Parts list

Copyright Swiftech 2001 – All rights reserved – Last revision date: Feb 1, 2002

Rouchon Industries, Inc., dbA Swiftech – 1703 E. 28

th

Street, Signal Hill, CA 90806 – Tel. 562-595-8009 – Fax 562-595-8769

E Mail: Swiftech @swiftnets.com – URL:

http://www.swiftnets.com

Information subject to change without notice

Page 1

Parts list

Parts

AMD

INTEL

QTY

PARTS

AMD

INTEL

QTY

Water-block, with TEC & gaskets assy.

X

1

Nylon 6-32 Hex nuts

Common to both

4

6-32 x 2” screws (for WB)

Common to both

4

Black fiber washers

X

4

Standoffs

Common to both

4

Thermal grease

Common to both

1

Springs

Common to both

4

Tube insert

Common to both

2

.230x.096 Nylon spacers

X

4

Pentium 4 brackets

X

2

.220x.046 Nylon spacers

X

4

4-40 socket screws

X

4

AMD motherboard gasket

X

1

Preamble:

This product is intended for expert users only. Please consult with a qualified technician for installation. Improper installation may result in

damage to your components.

Swiftech assumes no liability whatsoever, expressed or implied, for the use of these

products, nor their installation.

The following instructions are subject to change without notice. Please visit our web site at

www.swiftnets.com

for updates.

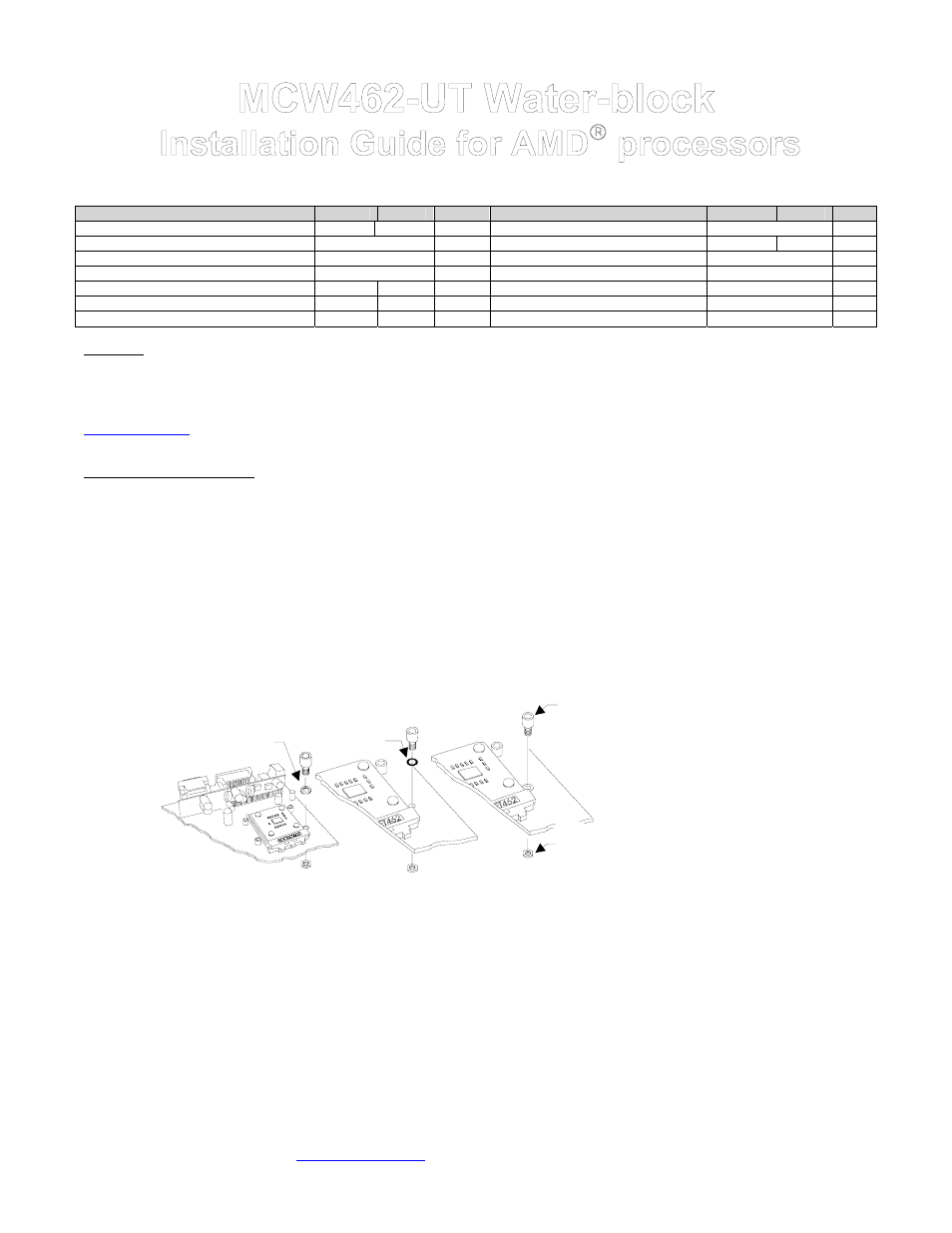

I. Preparing the motherboard

You must uninstall your MB prior to installing the MCW462-UT water-block.

•

Install standoffs in MB

Determine which standoff washers to use, depending on your MB mounting holes:

o

Large holes .230”(5.8mm) diameter : use .220x.046 Nylon spacers. The washers fit inside the MB hole.

o

Small grounded holes .150”(3.8mm) diameter: you can recognize grounding by a silver ring around the holes; no washers

needed nor necessary.

o

Small holes, NOT grounded (bare circuit board): you must use black fiber washers, or damage to the MB may occur.

MB with

large holes

MB with

small holes,

NOT grounded

MB with

small holes,

grounded

Use .220x.046

nylon spacer

(fit inside the hole)

Use black

Fiber washer

No washer

necessary

Standoff

Nylon, hex nut

on back side of

the MB

Figure 1

Install standoff in each one of the

four holes surrounding the socket.

Keep the standoff & washer

centered over the MB holes, and

secure with nylon hex nuts on

backside of the MB. If you are

going to assemble/disassemble the

heat sink frequently, we

recommend finishing the installation

by putting a drop of “Crazy Glue “ at

the junction between standoff & MB,

and between nylon hex nut & MB.

This will lock the standoff onto the

MB, and further prevent it from

spinning lose during frequent

assembly and disassembly

operations.

•

Fill-up the socket with dielectric grease. Do not confuse dielectric grease with thermal compound. Dielectric grease is used to

prevent condensation where parts are exposed to cold. We recommend Luberex (available on our web site under the accessories

section), or any similar product, with good dielectric properties. Fill-up the socket center cavity (grease is to be level with the upper

surface of the socket), and coat the socket pinholes with grease. Spread the grease with your finger so that it will penetrate inside

the pinholes.

•

Insert the processor into the socket. Since you have grease inside the socket, some hydraulic pressure lift may occur: for this

reason, make sure that the processor sits perfectly flat, and is inserted all the way into the socket. Then, lightly coat the processor

core with high quality thermal compound. Only a paper-thin coat is necessary. It should be applied using preferably a razor blade,

or a credit card, held between thumb and index at a 45-degree angle. It is critical to ascertain that the entire core is covered with a

uniform coat of thermal compound. Thermal performance will dramatically decrease if any portion of the core is not covered by

thermal compound. We recommend Arctic Silver or similar high-end compound for superior thermal conductivity.