Iii. installation for amd platforms – Swiftech MCW20 R User Manual

Page 3

Swiftech Inc., 1703 E. 28

th

St., Signal Hill, CA 90755 T. (562) 595-8009 F. (562) 595-8769

Page 3 of 2

3.

Connect the block to the rest of the cooling circuit.

4. Type of Coolant:

a.

For best performance, use 95% distilled water, and 5% Swiftech brand “HydrX” corrosion inhibitor (available here:

“accessories” section).

b.

In ALL cases, you MUST use Distilled water AND a corrosion inhibitor with the MCW5002 water-block. Regular

automotive anti-freeze is acceptable. Automotive manufacturers recommend that not less than 25% is used.

c.

NEVER use tap water, even for a short-term test.

d.

Not following paragraphs b and c above constitutes misuse (*) of the product, and will void your warranty.

4.

Final inspection

Once the installation is completed, it is always a good idea to test the circuit for leaks, prior to powering up the computer. If

using Swiftech’s fill-and-bleed kit, such test can be done without any liquid into the circuit. Please refer to the FBK525

installation

guide for details. Troubleshooting help is available on our

, or by calling customer support at 562-595-

8009.

III. Installation for AMD

platforms

1. Preparing

your

Motherboard

Remove the motherboard from the chassis

Remove the existing heat sink

Carefully clean the microprocessor, using alcohol

2. Installing

MCW20-A™

water-block

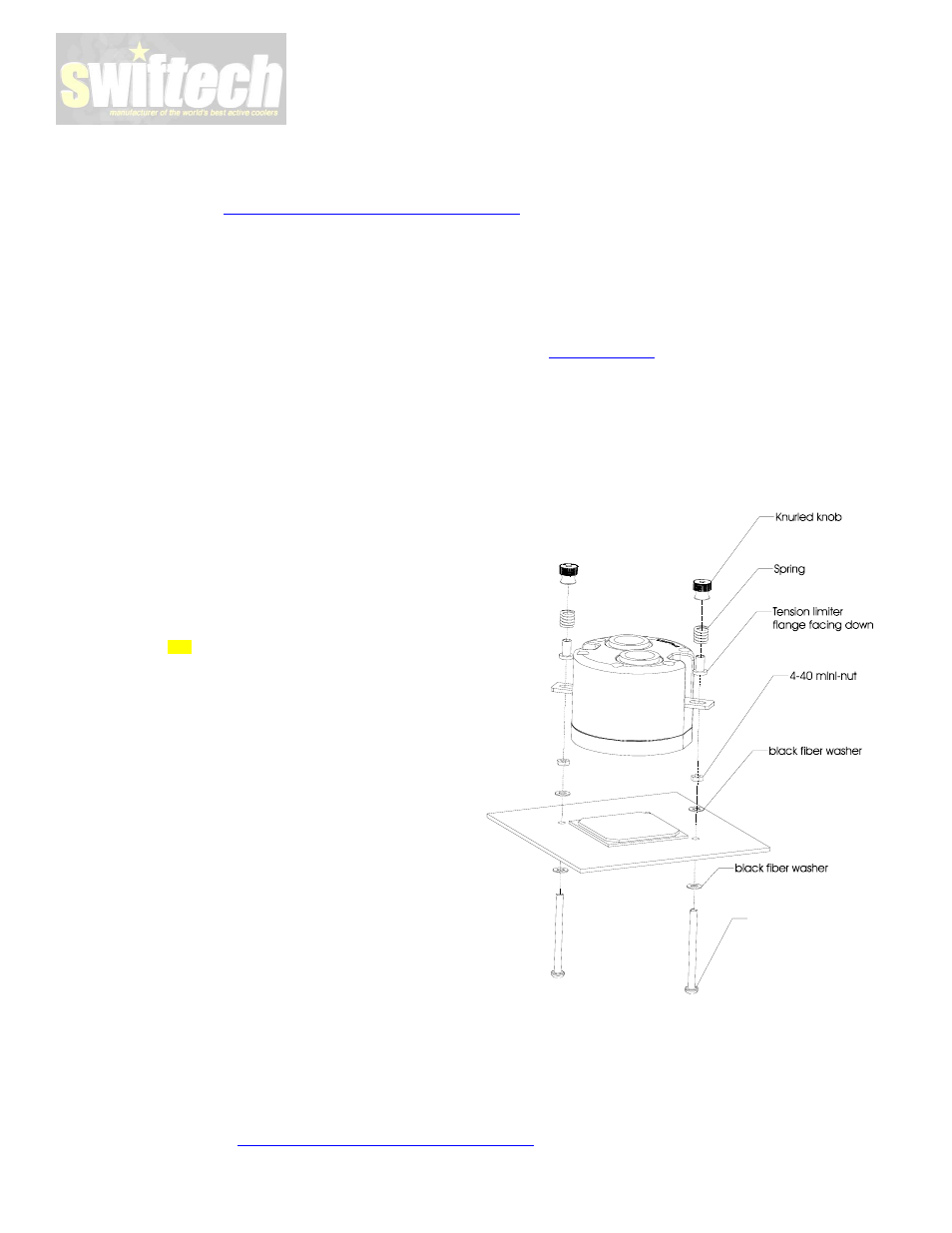

Install the provided screws through the motherboard,

using a black fiber washer on both sides of the

motherboard, and tighten the nuts.

Install the motherboard back into the chassis

Lightly coat the microprocessor with the provided

thermal compound. Only a paper-thin coat is necessary. It

should be applied using preferably a razor blade, or a credit

card, held between thumb and index at a 45-degree angle.

TIP! It is preferable to have the tubing inserted into the

water-block BEFORE you install the block onto the

motherboard. This is because pushing the tubes into the

block while it is already installed could exert undue

pressure onto the microprocessor.

Slide down the MCW20-A over the retention screws,

as shown figure 10, then install the nylon tension limiters

(flange facing down), the springs, and tighten the assembly

with the knurled knobs. Over tightening of the assembly is

prevented by the tension limiter. Users should be cautious

nonetheless, as nylon can be easily crushed.

4-40 x 1 1/2“ philips screw

Figure 10

3.

Connect the block to the rest of the cooling circuit.

The block is designed in such a way that it will bleed itself automatically in any vertical orientation (computer standing-up).

4.

Type of Coolant:

a.

For best performance, use 95% distilled water, and 5% Swiftech brand “HydrX” corrosion inhibitor (available here:

“accessories” section).