Installing the ldt in a hydraulic cylinder, Figure 2-1: mounting the ldt – AMETEK 953 VMAX LDT User Manual

Page 5

5

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

AUTOMATION & PROCESS TECHNOLOGIES

®

required. Stress between the magnet and the rod

can cause flexing of the mounting brackets. This

may result in non-linearity.

• LDTs using a split magnet assembly must keep

the diameter of the magnet assembly around the

rod throughout the complete stroke. The diameter

of this magnet assembly should not be more than

0.2” away from the rod. Split magnet assemblies

outside of this range will cause signal loss.

To install the magnet assembly, perform the following

steps:

1. Slide the magnet assembly over the LDT rod.

2. Mount the magnet to the non-ferrous, movable

portion of the device being controlled using non-

ferrous screws.

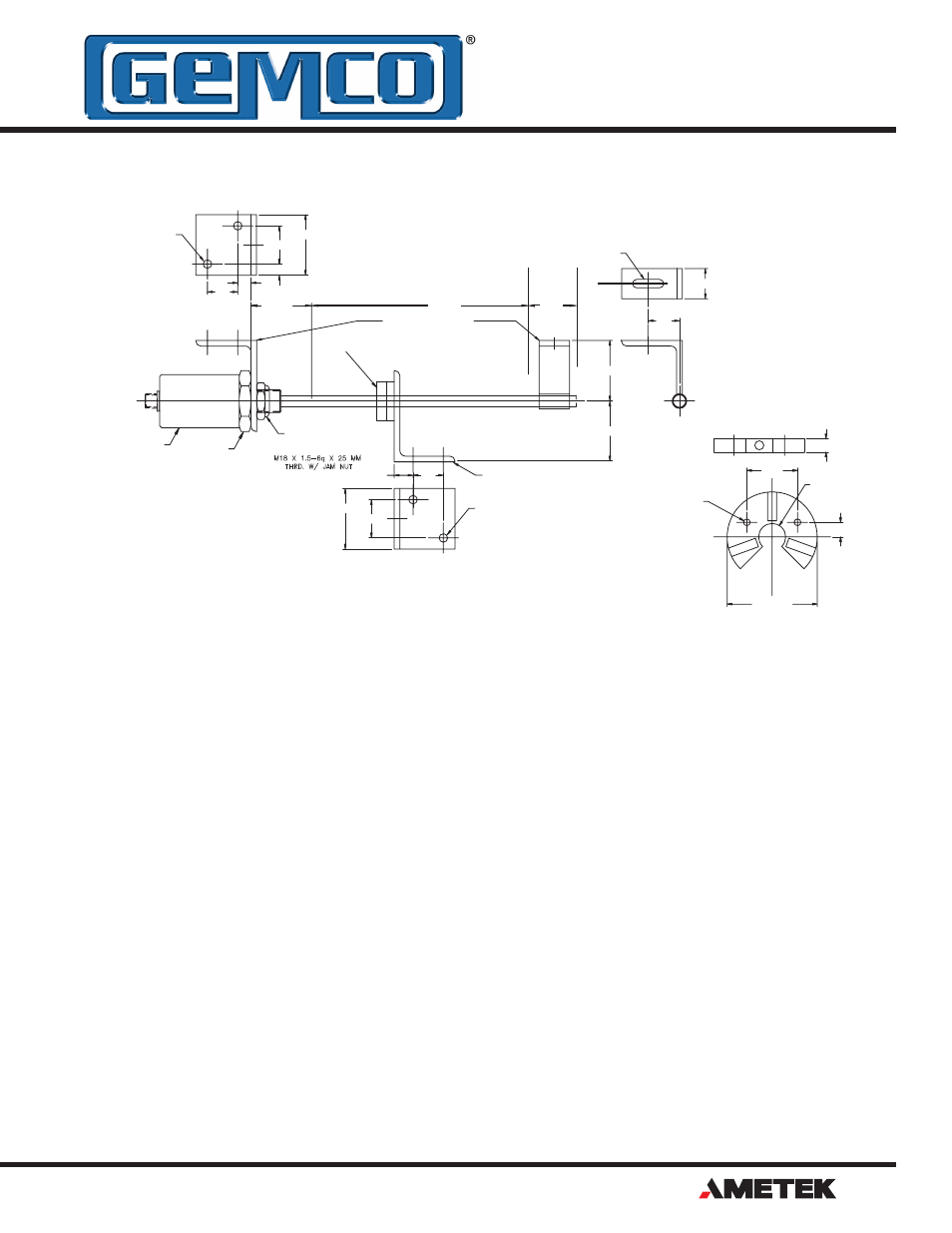

2.2: Installing the LDT in a

Hydraulic Cylinder

Before installing an LDT in a hydraulic cylinder, note

the following considerations. Items discussed in this

section are found in Figures 1-1 and 2-1.

• A non-ferrous spacer must be used to separate the

magnet assembly from the head of the piston rod.

See Figure 2-2.

• The magnet should not be closer than 2.0” from the

base of the LDT’s hex head when the piston rod is

fully retracted. In instances where space restraints

exist, it may be required to countersink the magnet

into the piston rod. Two magnets are available

for mounting to the piston: the standard 1.29"

in diameter (P/N SD0400800) four-hole magnet

and the 1.0" magnet (P/N SD0410300) designed

exclusively for countersunk mounting applications.

The 1.0" magnet must be secured with a snap ring.

Figure 2-1: Mounting the LDT

BAN D

OPTIONA

OR

L

OPTIONAL

MAGNE T

NUL L

STROK E

DEAD

1.75 HE X

MAGNET MOUNTIN G

KIT (P/N 949005)

PROBE MOUNTING KI T

(P/N 949003)

2.00

2.00

3/4-16 JAM NUT

SUPPLIED W/PROB E

1.00

1.03

.28 X 1.03 SLOT

1.00

.4 4

1.25

2.00

.2 8

2 PLACES

2.00

1.25

1.00

2 PLACES

.2 8

.6 2

PROB E

3/16" X 2" X3" STAINLESS STEEL .

2. MOUNTING BRACKETS ARE MADE FROM

MOUNTING BOLTS.

1. MOUNTING KITS FURNISHED WITH

NOTES: UNLESS OTHERWISE SPECIFIE D

C

L

.3 7

2.50 REF .

.406

1.407

.75 THRU

.38

.187 THRU

(2 PLACES)

S

N

N

N

S

S

S

NOTE: USE THIS MAGNET WITH ROD

SUPPORT BRACKET SD0411100