Appendix b: part numbering – AMETEK 953 VMAX LDT User Manual

Page 15

15

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • Phone 248.435.0700 • Fax 248.435.8120 • www.ametekapt.com

AUTOMATION & PROCESS TECHNOLOGIES

®

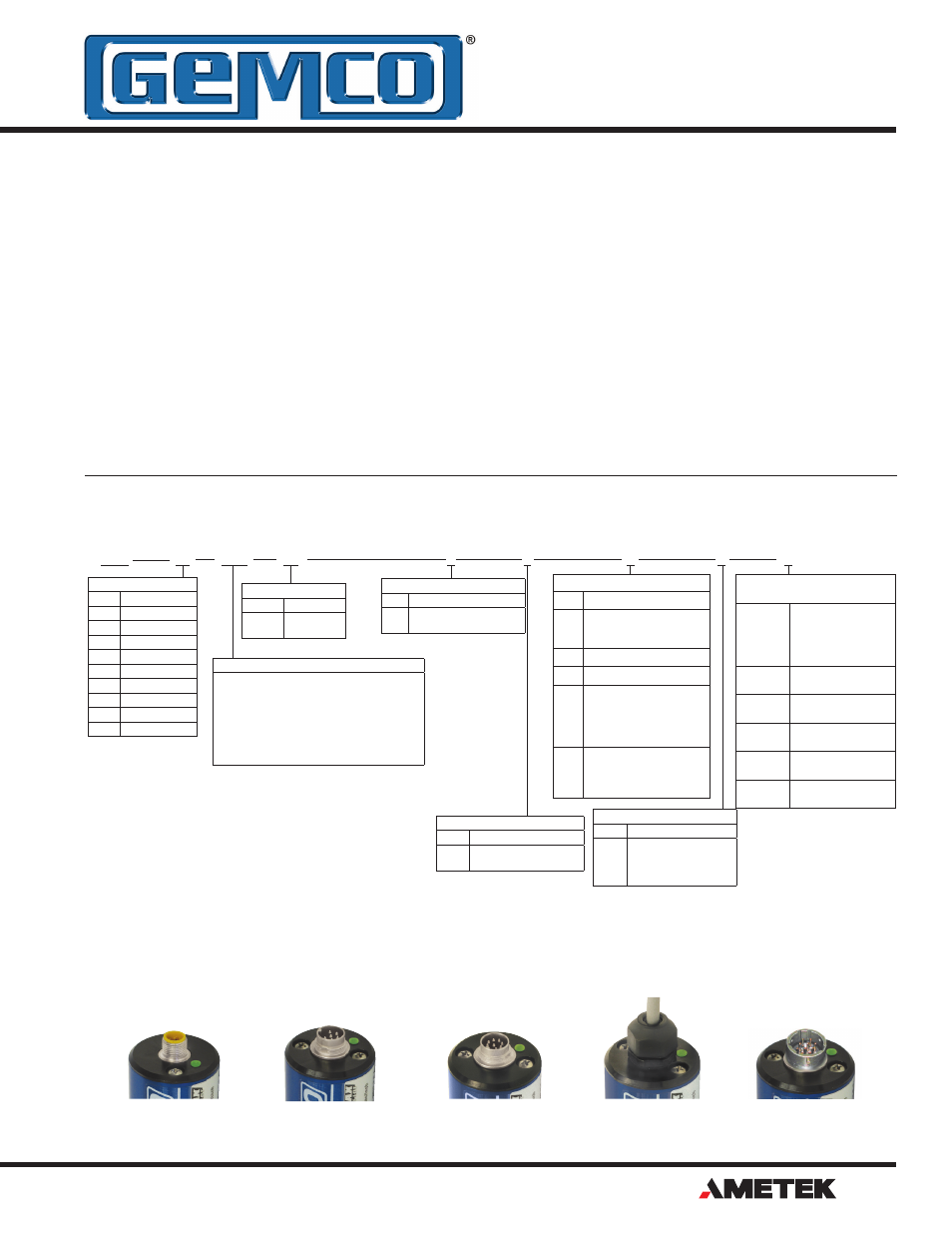

Appendix B: Part Numbering

to power the LDT. When powering more than one

VMAX on a single power supply, remember that each

unit requires approximately one watt of

power. The amount of current draw will vary based on

the input voltage used. To calculate the current draw

for a particular LDT, divide the LDT wattage by the

input voltage. For example, 1 watt divided by 24 VDC

equals 41.6mA.

If the LDT is not operating properly, the LDT’s cable

may have an open or short, or the power supply is not

supplying sufficient power. To verify this:

1. Turn the power supply off.

2. Remove the mating connector from the LDT.

3. Turn the power supply on.

4. Using a digital voltmeter, check across Power Supply

Common and customer supplied power (+VDC) on

the mating end of the cable for a level between 7 and

30 VDC.

Appendix B: Part Numbering

NOTE: LDT’s with integral cable assemblies

should be checked for proper voltage at the power

supply terminals. This cable assembly cannot be

removed from the LDTIf the reading is between 7

and 30 VDC, turn power supply off and go to step

7. If the reading is below 7 VDC, either the power

supply is not providing enough power or the LDT’s

cable possibly has a short or open. A reading of

no voltage or minimal voltage (less than 5 volts)

may be due to a short or open in the cable. If the

reading is not between 7 and 30 VDC, go to step

5. If the reading is above 30 VDC, adjust power

supply or replace.

5. Turn the power supply off.

6. Check the continuity of the individual wires of

the cable between the power supply and the

LDT. Check for continuity from one end of the

cable to the other. Also, verify that no shorts

exist between pins.

7. Reconnect the mating connector to the LDT.

953A

0120

V0

X

Stroke Length

Insert stroke length to 0.1 inch. Enter as a four-

place number. Example: A 12.0” stroke enters as

0120.

OR

Insert stroke in millimeters to 1mm. Enter as a

four-place number. Example: 305mm stroke entered

as 0305M. Metric length includes metric mounting,

M18x1.5. Unless specified otherwise.

S

X

X

Null Zone

X

Standard 2 inches.

N_ Insert non-standard Null

Zone (1.5" Minimum).

Options

X

None

S

Stainless Steel cover and

connector. Only available

with connector options S,

C and H.

Dead Band

X

Standard 2.5 inches.

D_

Insert non-standard Dead

Band (2.25" Minimum).

Output

V0

0 to 10 VDC

V1

10 to 0 VDC

V2

-10 to 10 VDC

V3

10 to -10 VDC

V4

0 to 5 VDC

V5

5 to 0 VDC

V6

-5 to 5 VDC

V7

5 to -5 VDC

C4

4 to 20mA

C2

20 to 4mA

Connector Option

S

Standard 5 Pin, 12mm Euro

C_

Integral Cable Assembly.

Insert length in feet. Example:

C6 = 6 foot cable.

M

6 Pin DIN, MTS Style D60

B

8 Pin DIN, Balluff S32

E

Environmental 10 Pin MS

Connector compatible w/951 &

952 LDTs

w/connector option “E”.

H_

High Temp., Integral cable

assembly 200 C Teflon Cable.

Insert length in feet. Example: H6=

6 foot High Temp Teflon Cable.

o

Optional Housing Style

Mounting Threads

Blank

Raised face hex base

(Standard) - Threads will

be the same as "Units

of Measure" unless

specified otherwise.

R

US Threads with raised

face hex base

F

US Threads with flat

face hex base

M

Metric Threads with

raised face hex base

N

Metric Threads with flat

face hex base

C

Sensor cartridge only

No hex base

NOTE 1: On unsupported stroke

lengths greater

than 4 feet, rod support bracket(s)

and a special magnet

should be used.

NOTE 2: Specify magnet as sepa-

rate line item.

Standard magnet is SD0400800.

VP

Units

Blank Inches

M

Metric Base

and Threads

S Connector Style

5 Pin Micro, 12mm Euro

M Connector Style

6 Pin DIN, Fits MTS D60

B Connector Style

8 Pin DIN, Fits Balluff S32

C Connector Style

Integral Cable Assembly

E Connector Style

10 Pin MS Connector,

Fits Gemco 951 & 952 Wiring