State CSB 120 54 IFE User Manual

Page 13

13

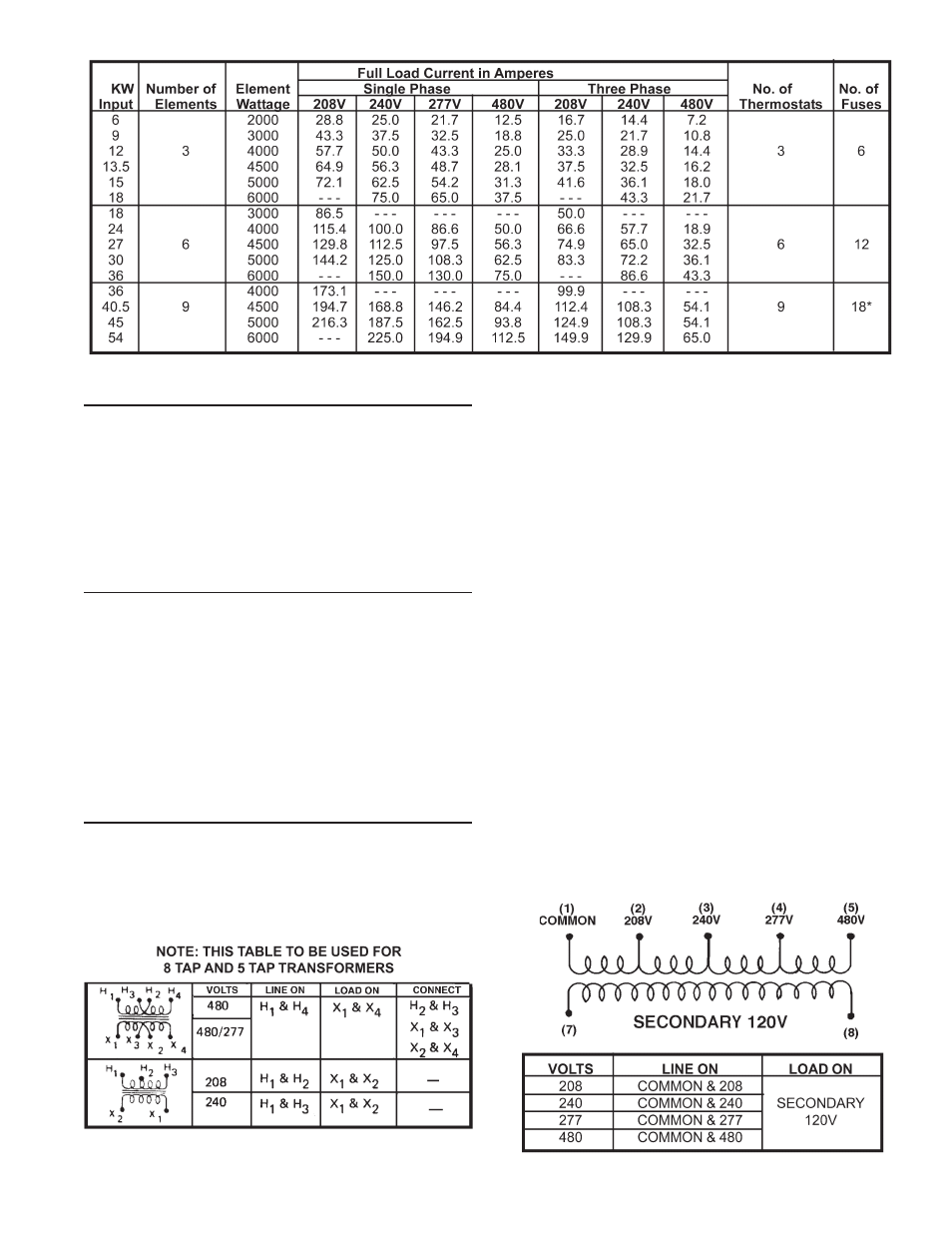

AMPErAGE tABLE/oVErCurrEnt ProtECtIon

The tables above provides the total connected heating element load

in amperes for branch circuit conductor and overcurrent protection

sizing. Single-phase heaters are two wire circuits. Three-phase

heaters are three wire circuits. In addition to the foregoing, a

grounded conductor is required.

The rating of the overcurrent protection must be computed on the basis

of 125% of the total connected load amperage. Where the standard

ratings and settings do not correspond with this computation, the next

higher standard rating or setting should be selected.

hEAtEr CIrCuIts - ELECtronIC ControL ModELs

The water heater’s electrical components are pictured and identified

in Figure 2. and Figure 3. The model and rating plate illustration on

page 4 identifies heater circuit ratings. The ELECTRONIC CONTROL

model has two electrical circuits:

• The control circuit, which controls the electrical power to heating

elements, referring the following control circuit diagram Figure 6.

• The power circuit, which is operated by the control circuit carries

the electrical load of the heating elements. The following

describes the heater circuits and includes wiring diagrams for

Delta configuration, refer to the “WYE Configuration Insert” for

water heaters operating at 380V/400V/416V/575V. All heater

circuits are designed for 50/60 cycle alternating current.

ControL CIrCuIt - ELECtronIC ControL ModELs

These models are equipped with an electronic control system. The

system includes a CCB (Central Control Board), an immersion

temperature probe with ECO for temperature sensing and limiting, a

UIM (User Interface Module) for user interface & information display

and element current sensors for monitoring the power circuits. Refer

to the control circuit label on the water heater for details. The CCB is

powered by a small 120V/24V transformer. The control circuit operates

on 120V supplied by a larger 100VA transformer. Standard equipment

includes control circuit fusing using two, 3 amp, class G fuses with 600

volt rating. Do not substitute fuses of a different rating.

Sequence of Operation

1. When the control is powered, the UIM should display model

information, water temperature, Operating Set Point, heating

status and operating mode.

2. If the control determines that the actual water temperature inside

the tank is below the programmed Operating Setpoint minus the (1st)

differential, a call for heat is activated.

3. After all safety checks are verified, the CCB will energize contactor

coils starting with the lower bank of heating elements (each diagonal

row of three heating elements is considered a “bank” - see Figure 2.)

then energize the middle bank (if so equipped) and top bank (if so

equipped). The middle and top banks (if so equipped) are energized

according to programmed 2nd and 3rd differential set points.

4. The control remains in the heating mode until the water temperature

reaches the programmed Operating Setpoint. At this point the

contactors will be de-energized in the reverse order.

5. The control system now enters the standby operating mode

while continuing to monitor the water temperature and the state

of other system devices. If the water temperature drops below

the programmed Operating Setpoint minus the (1st) differential,

the control will automatically return to step 2 and repeat the

heating cycle.

NOTE: See the Electronic Control Models Operation section for more

detailed information on temperature settings mentioned above.

120 VAC ControL CIrCuIt trAnsforMEr ConnECtIons - ELECtronIC ControL ModELs

table 4.

table 5.

figure 4.

figure 5.

- CSB 120 45 IFE CSB 120 405 IFE CSB 120 36 IFE CSB 120 30 IFE CSB 120 27 IFE CSB 120 24 IFE CSB 120 18 IFE CSB 120 15 IFE CSB 120 135 IFE CSB 120 12 IFE CSB 120 9 IFE CSB 120 6 IFE CSB 82 54 IFE CSB 82 45 IFE CSB 82 405 IFE CSB 82 36 IFE CSB 82 30 IFE CSB 82 27 IFE CSB 82 24 IFE CSB 82 18 IFE CSB 82 15 IFE CSB 82 135 IFE CSB 82 12 IFE CSB 82 9 IFE CSB 82 6 IFE CSB 52 54 IFE CSB 52 45 IFE CSB 52 405 IFE CSB 52 36 IFE CSB 52 30 IFE CSB 52 27 IFE CSB 52 24 IFE CSB 52 18 IFE CSB 52 15 IFE CSB 52 135 IFE CSB 52 12 IFE CSB 52 9 IFE CSB 52 6 IFE