Diagnostic link connectors (dlc), Obd ii (j1962), Di agnostic link connectors (dlc) – Actron KAL9640B User Manual

Page 18

Getting Started

2 – 4 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

2

SAE publishes recommendations, not laws, but the Environmental Protection

Agency (EPA) and California Air Resources Board (CARB) made many of

SAE’s recommendations legal requirements that vehicle manufacturers were

required to phase in over a three-year period. Beginning in 1994, vehicles with

a new engine management computer – about 10% of each manufacturers fleet

– were supposed to comply with OBD II standards. For 1995, OBD II systems

were to appear on about 40% of the new vehicles sold in the USA. Some of the

1994-1995 OBD II systems were not fully compliant, so the Government

granted waivers to give manufacturers time to fine-tune their systems.

Beginning in 1996, most of the new vehicles sold in the USA were fully OBD II

compliant.

DIAGNOSTIC LINK CONNECTORS (DLC)

The Data Link Connector (DLC) allows the scan tool to communicate with the

vehicle’s computer(s). Before OBD II, manufacturers used different data link

connectors to communicate with the vehicle. The proper DLC adapter cable

must be used to connect the tool to the vehicle. Also, the vehicle’s DLC may be

found in several different places and have many different configurations. The

following describes the DLCs used by Ford, GM and Chrysler. The DLC location

and types for domestic vehicles can be looked up in the charts in “Appendix

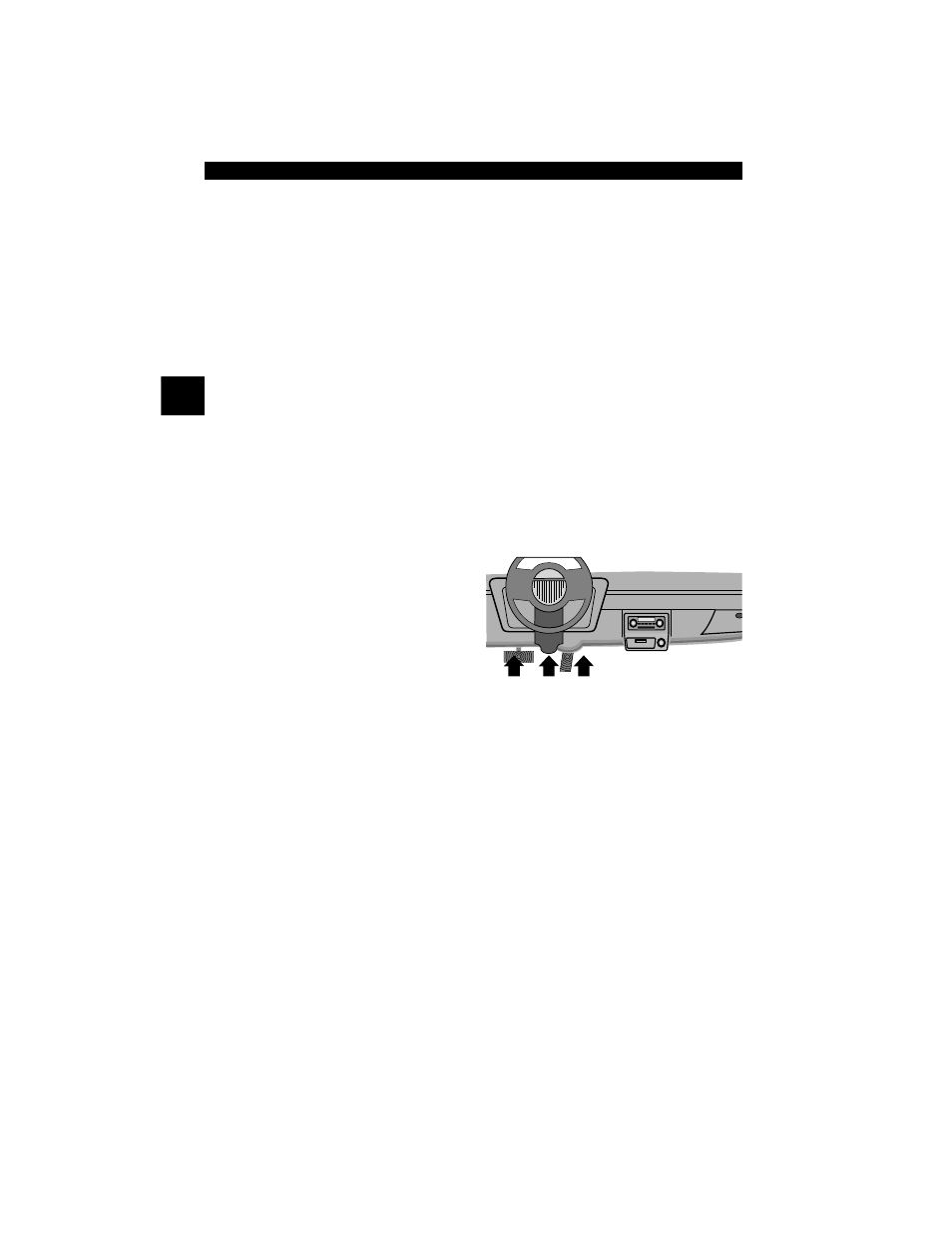

OBD II (J1962)

Beginning in 1996, vehicles sold in

the United States use the J1962

(OBD II) DLC, a term taken from a

physical and electrical specification

number assigned by SAE (J1962).

The DLC should be located under

the dashboard on the driver side of

the vehicle. If the DLC is not located under the dashboard as stated, a decal

describing its location should be attached to the dashboard in the area the DLC

should have been located.

Because the OBD II J1962 connector has power and ground, you only need a

single cable connection to the tool for both power and tool communications.

Attach the OBD II adapter cable to the extender cable, both supplied with the

tool, to connect the tool. Certain pins in the connector are reserved