CMP PXSS2K-REX User Manual

Page 2

INSTALLATION INSTRUCTIONS FOR CMP CABLE GLAND TYPE PXSS2K-REX

DUBAI

• HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

DUBAI

• HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

www.cmp-products.com

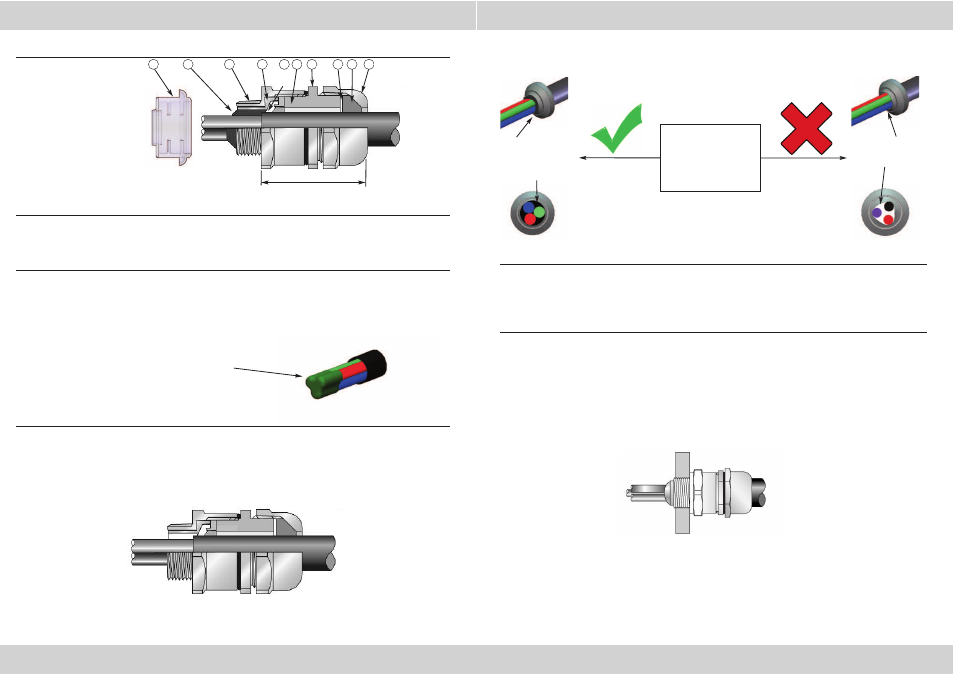

CABLE GLAND COMPONENTS

1. Separate the gland components by removing the main item (6) and outer seal nut assembly (7, 8, 9).

Slacken the outer seal nut slightly to relax the seal and pass the main item/outer seal nut assembly

over the cable, nut end first.

Prepare the cable by stripping back the outer sheath to suit the equipment.

2. Remove any bedding or fillers from around the cable cores. If the cable cores have screens, these

should be unravelled and then twisted together to form a single core.

This single core and/or any drain wires present should be sleeved with some heat shrink tubing.

3. Feed the cable carefully into the entry item (2) through the resin dam (4). Reassemble the gland

and adjust the position of the cable if necessary to that the outer sheath just protrudes through the

resin dam. (Use length ‘L’ as a guide for positioning the cable). Tighten the outer seal nut enough to

secure the gland.

N.B. If the outer sheath is too large to pass through the spacer then wrap some electrical tape around

the cores at the point they pass through the resin dam.

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

4. Refer to ‘RapidEx Resin’ assembly instructions to fill the connector Compound Tube

with the required amount of resin. The resin should not be mixed or applied at

temperatures below 5°C (40°F).

5. Once the resin has cured remove the thread shield, loosen the outer seal nut and remove the

main item (6) and outer seal nut assembly (7,8,9) from the entry item (2). Fit the entry item into

the equipment.

6. Re-install the cable assembly into the entry item and fully tighten the main item (6) onto the

entry item (2). Tighten the outer seal nut (9) until it comes to an effective stop. This will occur

when :-

A) The outer seal nut (9) has clearly engaged the cable and cannot be further tightened

without the use of excessive force by the installer.

B) The outer seal nut (9) is metal to metal with the main item (6).

6

3

4

2

1. Resin

2. Entry Component “A”

3. Compound Tube

4. Resin Dam

5. Spacer

6. Main Item

7. Skid Washer

8. Outer Seal

9. Outer Seal Nut

10. Thread Shield

8

7

9

Resin Dam with

good contact

with cable sheath

or electrical tape.

Resin Dam with

poor contact

with cable

cores.

Ensure Resin Dam is

in position in the

gland and making a

good seal against the

inner sheath.

Do not disassemble the gland to inspect the Resin Dam, diagrams

are for representation.

Electrical tape MUST be wrapped around the tips of the

cable cores. This is to ensure the cable cores are

together and also to cover any sharp edges that could

potentially tear the Resin Dam during installation.

10

Resin

Dam

1

5

‘L’