CMP T3CDSX User Manual

Cable gland, Cable gland type t3cdsx type t3cdsx

INSTALLATION INSTRUCTIONS FOR

INSTALLATION OF CMP CABLE

GLAND TYPES T3CDSX

CABLE GLAND FOR USE WITH WIRE BRAID, STRIP, AND TAPE ARMOUR FOR USE IN HAZARDOUS

LOCATIONS.

INCORPORATING EC DECLARATION OF CONFORMITY TO DIRECTIVE 94/9/EC

CMP TRITON

TM

CDS

TM

DELUGE PROOF CABLE GLAND FEATURING

COMPENSATING DISPLACEMENT SEAL SYSTEM.

CM

P

Do

cu

m

en

tN

o.

FI

40

9

Is

su

e

4

01

/1

3

0518

Glasshouse Street • St. Peters • Newcastle upon Tyne • NE6 1BS

Tel: +44 191 265 7411 • Fax: +44 191 265 0581

E-Mail: [email protected] • Web: www.cmp-products.com

Notified Body: Sira Certification Service, Rake Lane, Chester CH4 9JN, England.

DUBAI

• HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

Ca

bl

e

Gl

an

d

Se

le

ct

io

n

Ta

bl

e

Logo’s shown for illustration purposes only. Please check certification for details

*

For IP67 & IP68 requirements the Cable Diameter “B” (minimum value) shown above should be increased by 1.0 mm to ensure complete compliance

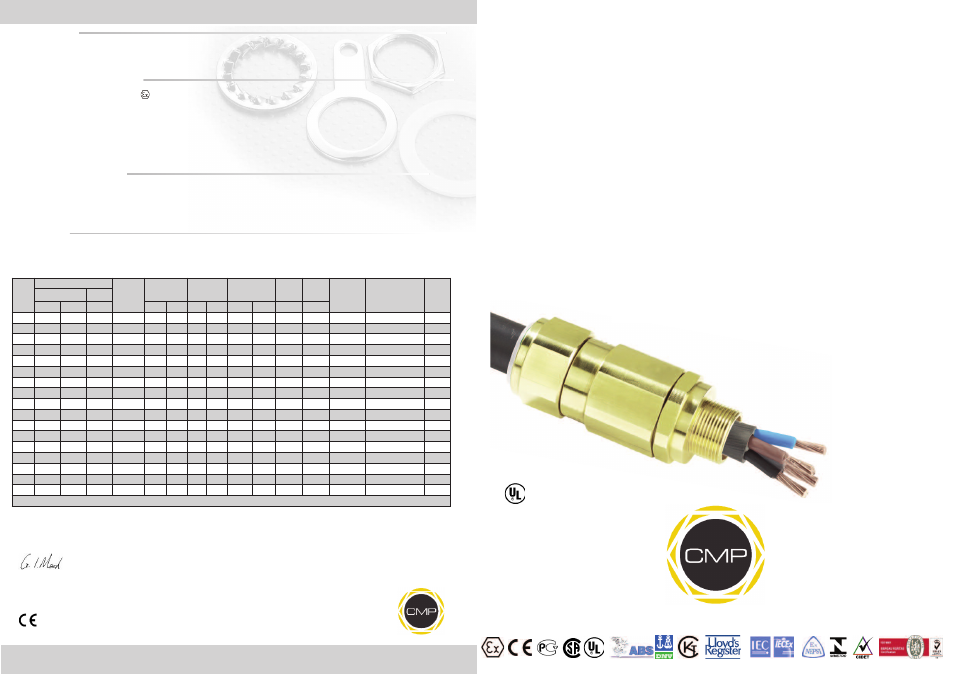

CABLE GLAND

CABLE GLAND

TYPE T3CDSX

TYPE T3CDSX

Cable

Gland

Size

Available Entry Threads

Minimum

Thread

Length

Cable

Bedding

Diameter

Overall Cable

Diameter

Braid Wire

Diameter

Across

Flats

Across

Corners Protrusion

Length

Ordering Reference

(Brass Metric)

Cable

Gland

Weight

(Kgs)

Standard

Option

Metric

NPT

NPT

Min

Max

Min

Max

Min

Max

Max

Max

20S/16

M20

1/2"

3/4"

15.0

3.2

8.7

6.1

13.4

0.15

0.5

24.0

25.9

70.0

20S16T3CDSX1RA

0.170

20S

M20

1/2"

3/4"

15.0

6.1

11.7

9.5

15.9

0.15

0.5

24.0

25.9

70.0

20ST3CDSX1RA

0.170

20

M20

1/2"

3/4"

15.0

6.5

14.0

12.5

20.9

0.2

0.5

30.5

32.9

72.0

20T3CDSX1RA

0.256

25S

M25

3/4"

1"

15.0

11.1

20.0

14.0

22.0

0.2

0.6

37.5

40.5

82.0

25ST3CDSX1RA

0.384

25

M25

3/4"

1"

15.0

11.1

20.0

18.2

26.2

0.2

0.6

37.5

40.5

82.0

25T3CDSX1RA

0.379

32

M32

1"

1 1/4"

15.0

17.0

26.3

23.7

33.9

0.2

0.6

46.0

49.7

85.0

32T3CDSX1RA

0.560

40

M40

1 1/4"

1 1/2"

15.0

23.5

32.2

27.9

40.4

0.2

0.8

55.0

59.4

86.0

40T3CDSX1RA

0.848

50S

M50

1 1/2"

2"

15.0

31.0

38.2

35.2

46.7

0.2

0.8

60.0

64.8

98.0

50ST3CDSX1RA

1.055

50

M50

2"

2 1/2"

15.0

35.6

44.1

40.4

53.1

0.3

0.8

70.0

75.6

100.0

50T3CDSX1RA

1.521

63S

M63

2"

2 1/2"

15.0

41.5

50.0

45.6

59.4

0.3

0.8

75.0

81.0

108.0

63ST3CDSX1RA

1.750

63

M63

2 1/2"

3"

15.0

47.2

56.0

54.6

65.9

0.3

0.8

80.0

86.4

103.0

63T3CDSX1RA

1.685

75S

M75

2 1/2"

3"

15.0

54.0

62.0

59.0

72.1

0.3

0.8

89.0

96.1

105.0

75ST3CDSX1RA

2.345

75

M75

3"

3 1/2"

15.0

61.1

68.0

66.7

78.5

0.3

0.8

99.0

106.9

114.0

75T3CDSX1RA

3.200

90

M90

3"

3 1/2"

15.0

66.6

79.3

76.2

90.4

0.4

0.8

114.0

123.1

140.0

90T3CDSX1RA

5.100

100

M100

4"

4 1/2"

15.0

76.0

91.0

86.1 101.5

0.4

0.8

123.0

132.8

170.0

100T3CDSX1RA

6.500

115

M115

4 1/2"

5"

15.0

86.0

98.0 101.5 110.3

0.4

0.8

133.4

144.1

210.0

115T3CDSX1RA

7.000

130

M130

5"

6"

15.0

97.0

115.0 114.2 123.3

0.4

0.8

146.1

157.8

250.0

130T3CDSX1RA

7.800

Dimensions are displayed in millimetres unless otherwise stated

TECHNICAL DATA

CABLE GLAND TYPE

: T3CDSX

INGRESS PROTECTION

: IP66, NEMA 4X, DELUGE TO DTS01-01, Oil Resistan

PROCESS CONTROL SYSTEM

: BS EN ISO 9001

: ISO/IEC 80079-34:2011

HAZARDOUS AREA CLASSIFICATION

ATEX CERTIFICATION No

: SIRA 06ATEX1283X & SIRA 06ATEX4328X

ATEX CERTIFICATION CODE

:

II 2 GD Ex d IIC / Ex e II / Ex nR II / Ex tD A21 IP66

IEC Ex CERTIFICATION No

: IEC Ex SIR.07.0005X

IEC Ex CERTIFICATION CODE

: Ex d IIC / Ex e II / Ex nR II / Ex tD A21 IP66

CSA-US CERTIFICATION No

: CSA.02.310517X

CSA-US CERTIFICATION CODE

: Class I, Div 2, Groups ABCD; Class II, Div 2, Groups EFG; Class III; Ex d IIC; Ex e II;

Class I, Zone 1, AEx d IIC; Class I, Zone 1, AEx e II

UL CERTIFICATION FILE

: E200163

UL CERTIFICATION CODE

: Class I, Zone 1, AEx II; TYPE 4X, OIL RES II

INSTALLATION INSTRUCTIONS

Installation should only be performed by a competent person using the correct tools. Read all instructions before beginning installation.

SPECIAL CONDITIONS FOR SAFE USE

1. The glands ranges shall only be used on enclosures where the temperature, at the point of mounting, is in the range -60°C to +130°C.

2. When used with braided cable, the cable glands shall be used for fixed installations only. Cables must be effectively clamped to prevent twisting

and pulling.

3. When used in Group I applications, the equipment must only be mounted where the risk of mechanical impact is low.

4. According to CEC Wiring methods, connectors with Metric entry threads are only suitable for Areas classified in ZONES unless fitted with an

approved Metric to NPT thread conversion adaptor.

ACCESSORIES

The following accessories are available from CMP Products, as optional extras, to assist with fixing, sealing and earthing :-

Locknut | Earth Tag | Serrated Washer | Entry Thread (I.P.) Sealing Washer | Shroud *

I, The undersigned, hereby declare that the equipment referred to herein conforms to the requirements of the ATEX Directive 94/9/EC and the following

standards:-

EN60079-0:2006, EN60079-1:2007, EN60079-7:2007, EN60079-15:2005, BS 6121:1989, EN50262:19989 (Amd 2001), EN61241-0:2004, EN61241-1:2004

Dr Geof Mood - Technical Director - (Authorised Person)

LISTED MARINE

SHIPBOARD CABLE

FITTING

31YM