CMP E2FU User Manual

Cable gland types

INSTALLATION INSTRUCTIONS FOR

CMP CABLE GLAND TYPE “E”

FOR TERMINATION OF CABLES WITH WIRE BRAID, TAPE ARMOUR (STA/DSTA), STRIP ARMOUR &

SINGLE WIRE ARMOUR (SWA) (WITH LEAD INNER SHEATH ON “E2” VARIANT). FOR USE IN

HAZARDOUS LOCATIONS.

INCORPORATING EC DECLARATION OF CONFORMITY TO DIRECTIVE 94/9/EC

CM

P

Do

cu

m

en

tN

o.

FI

40

7

Is

su

e

5

01

/1

3

0518

Glasshouse Street • St. Peters • Newcastle upon Tyne • NE6 1BS

Tel: +44 191 265 7411 • Fax: +44 191 265 0581

E-Mail: [email protected] • Web: www.cmp-products.com

Notified Body: Sira Certification Service, Rake Lane, Chester CH4 9JN, England.

I, the undersigned, hereby declare that the equipment referred to herein conforms to the requirements of the ATEX Directive 94/9/EC and the following

standards:-

EN60079-0:2009, EN60079-1:2007, EN60079-7:2007, BS 6121:1989, EN50262:1998 (Amd 2001), EN61241:0-2004, EN61241-1:2004

Dr Geof Mood - Technical Director - (Authorised Person)

DUBAI

• HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

Ca

bl

e

Gl

an

d

Se

le

ct

io

n

Ta

bl

e

Logo’s shown for illustration purposes only. Please check certification for details

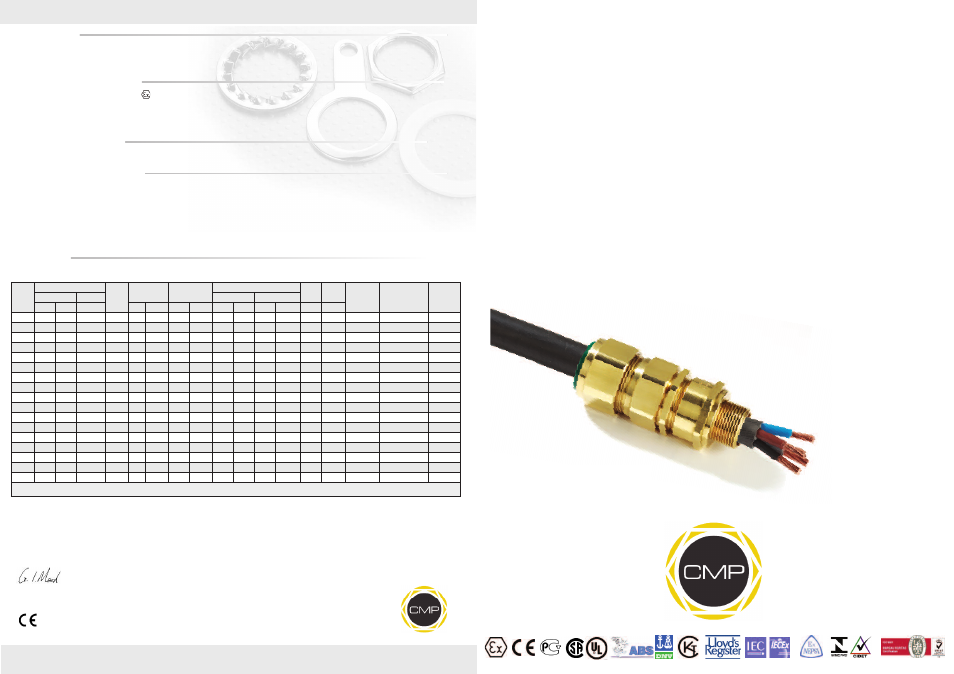

CABLE GLAND TYPES

CABLE GLAND TYPES

E1FW, E2FW, E1FX,

E1FW, E2FW, E1FX,

E2FX, E1FU & E2FU

E2FX, E1FU & E2FU

Order codes shown are for E1FU glands

For e.g. E1FW glands substitue E1FW for E1FU - e.g. 20E1FW1RA

* Please note that the overall maximum cable bedding diameter for “E2” variants should be reduced by 1mm to allow for the inner lead sheath.

E1FW - SWA Armour

E2FW - SWA Armour for lead

sheathed cable

E1FX - Braid, Tape, etc Armour

E2FX - Braid, Tape, etc Armour for

lead sheathed cable

E1FU - Universal Gland for all

Armour Types

E2FU - Universal Gland for all

Armour Types with lead

sheathed cable

Cable

Gland

Size

Available Entry Threads

Thread

Length

metric

Cable Beding

Diameter

Overall Cable

Diameter

Armour Wire Diameter

Across

Flats

Across

Corners Protrusion

Length

Ordering

Reference

(Brass Metric)

PVC

Shroud

Ref

Standard

Option

Grooved Cone Stepped Cone

Metric NPT

NPT

Min

Max

Min

Max *

Min

Max

Min

Max

Max

Max

20S/16

M20

1/2”

3/4”

15.0

3.1

8.6

6.1

11.5

0.15

0.5

0.9

1.0

24.0

25.9

58.5

20S16E1FU1RA

PVC04

20S

M20

1/2”

3/4”

15.0

6.1

11.6

9.5

15.9

0.15

0.5

0.9

1.25

24.0

25.9

58.5

20SE1FU1RA

PVC04

20

M20

1/2”

3/4”

15.0

6.5

13.9

12.5

20.9

0.2

0.5

0.9

1.25

30.5

32.9

60.5

20E1FU1RA

PVC06

25S

M25

3/4”

1”

15.0

11.1

19.9

14.0

22.0

0.2

0.6

1.25

1.6

37.5

40.5

67.5

25SE1FU1RA

PVC09

25

M25

3/4”

1”

15.0

11.1

19.9

18.2

26.2

0.2

0.6

1.25

1.6

37.5

40.5

67.5

25E1FU1RA

PVC09

32

M32

1”

1-1/4”

15.0

17.0

26.2

23.7

33.9

0.2

0.6

1.6

2.0

46.0

49.7

69.5

32E1FU1RA

PVC11

40

M40 1-1/4”

1-1/2”

15.0

22.0

32.1

27.9

40.4

0.2

0.8

1.6

2.0

55.0

59.4

78.0

40E1FU1RA

PVC15

50S

M50 1-1/2”

2”

15.0

29.5

38.1

35.2

46.7

0.2

0.8

2.0

2.5

60.0

64.8

75.5

50SE1FU1RA

PVC18

50

M50

2”

2-1/2”

15.0

35.6

44.0

40.4

53.1

0.3

0.8

2.0

2.5

70.0

75.6

80.5

50E1FU1RA

PVC21

63S

M63

2”

2-1/2”

15.0

40.1

49.9

45.6

59.4

0.3

0.8

2.0

2.5

75.0

81.0

91.5

63SE1FU1RA

PVC23

63

M63 2-1/2”

3”

15.0

47.2

55.9

54.6

65.9

0.3

0.8

2.0

2.5

80.0

86.4

92.0

63E1FU1RA

PVC25

75S

M75 2-1/2”

3”

15.0

52.8

61.9

59.0

72.1

0.3

0.8

2.0

2.5

89.0

96.1

99.0

75SE1FU1RA

PVC28

75

M75

3”

3-1/2”

15.0

59.1

67.9

66.7

78.5

0.3

0.8

2.5

3.0

99.0

106.9

102.0

75E1FU1RA

PVC30

90

M90

3”

3-1/2”

24.0

66.6

79.9

76.2

90.4

0.4

0.8

3.0

3.5

114.0

123.1

120.0

90E1FU1RA

PVC32

100

M100

-

-

24.0

76.0

90.9

86.1

101.5

0.4

0.8

3.15

4.0

123.0

132.8

148.0

100E1FU1RA

LSF33

115

M115

-

-

24.0

86.0

97.9

101.5 110.3

0.4

0.8

3.15

4.0

133.4

144.1

169.0

115E1FU1RA

LSF34

130

M130

-

-

24.0

97.0 114.9

114.2 123.3

0.4

0.8

3.15

4.0

146.0

157.8

183.0

130E1FU1RA

LSF35

Dimensions are displayed in millimeters unless otherwise stated

TECHNICAL DATA

CABLE GLAND TYPE

: E** Family of Glands

INGRESS PROTECTION

: IP66, IP67, IP68

PROCESS CONTROL SYSTEM

: BS EN ISO 9001

: ISO / IEC 80079-34:2011

HAZARDOUS AREA CLASSIFICATION

ATEX CERTIFICATION No

: SIRA 06ATEX1097X & SIRA 07ATEX4326X

ATEX CERTIFICATION CODE

:

II 2 GD Ex d IIC / Ex e IIC / Ex nR II / Ex tD A21 IP66

IEC Ex CERTIFICATION No

: IEC Ex SIR.06.0043X

IEC Ex CERTIFICATION CODE

: Ex d IIC / Ex e IIC / Ex nR II / Ex tD A21 IP66

CSA CERTIFICATION No

: 02.1310517

CSA CERTIFICATION CODE

: Ex d IIC / Ex e II

INSTALLATION INSTRUCTIONS

Installation should only be performed by a competent person using the correct tools. Spanners should be used for tightening. Read all instructions

before beginning installation.

SPECIAL CONDITIONS FOR SAFE USE

For ATEX & IEC Ex certification:

1. The E type glands shall only be used where temperatures at the point of entry is between -60°C and +130°C.

2. E type glands used for terminating braided cables are only suitable for fixed installations. Cables must be clamped to prevent pulling or twisting.

3. An entry thread seal may be need to maintain the IP rating of the enclosure to which the E type gland is attached.

FOR CSA Certification:

1. These glands are not suitable for use with flameproof enclosures installed in Group IIC atmospheres which have a volume greater than 2000 cc (2

Litre).

2. These glands are for use with Certified Marine Shipboard metal braided cables constructed in according to CSA Std. 245 and

IEEE45/IEC600092-353 Standards, or Certified equivalent), for use on Shipboards and Offshore Rigs/Platfords only

ACCESSORIES

The following accessories are available from CMP Products, as optional extras, to assist with fixing, sealing and earthing :-

Locknut | Earth Tag | Serrated Washer | Entry Thread (I.P.) Sealing Washer | Shroud