Installation instructions for tc cable connector – CMP TC User Manual

Page 2

INSTALLATION INSTRUCTIONS FOR TC CABLE CONNECTOR

DUBAI

• HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

DUBAI

• HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

www.cmp-products.com

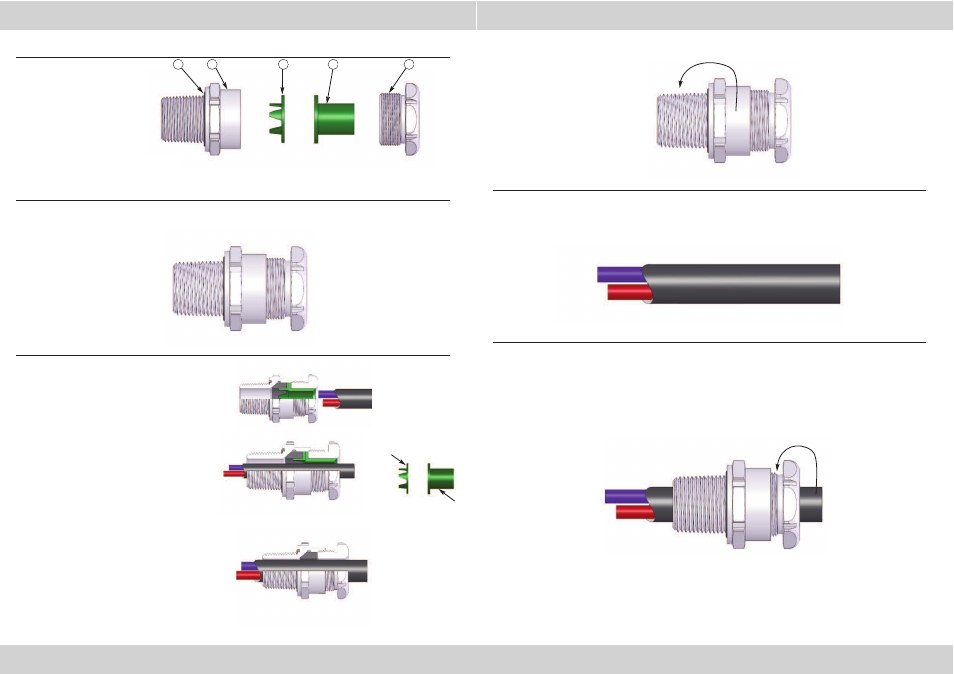

CABLE CONNECTOR COMPONENTS

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

1. If using the smaller cable range there is no need to disassemble the connector. (Size ranges are

marked on the connector).

5

3

4

2

1

1. “O” Ring

2. Entry Component

3. Seal Insert*

4. Nut Insert*

5. Seal Nut

2. Slacken the seal nut (5) to relax the seal.

Try to pass the cable through the connector. If

this is possible, move to stage 3.

If not dissassemble the connector and remove

the seal insert (3) and the nut insert (4).

This will allow the cable to pass through the

connector.

4. Determine the conductor length to suit the geometry of the equipment and prepare the cable

accordingly, removing part of the outer sheath where required to reveal the insulated conductors.

Note*:

The Seal and Nut inserts are only used in

connector sizes 40 (1-1/4”) and below to

give two cable size ranges.

Seal Insert 3

Nut Insert 4

3. Secure the complete connector into the equipment.

5. Pass the cable through the gland to the desired position hold the entry component (2) with a

spanner then tighten the seal nut until heavy resistance is felt. This will occur when:-

A) The seal nut (5) has clearly engaged the cable and cannot be further tightened without

the use of excessive force by the installer.

B) The seal nut (5) is metal to metal with the entry component (2). (This should only

happen on minimum cable sizes.)