CMP TMC2X User Manual

Page 2

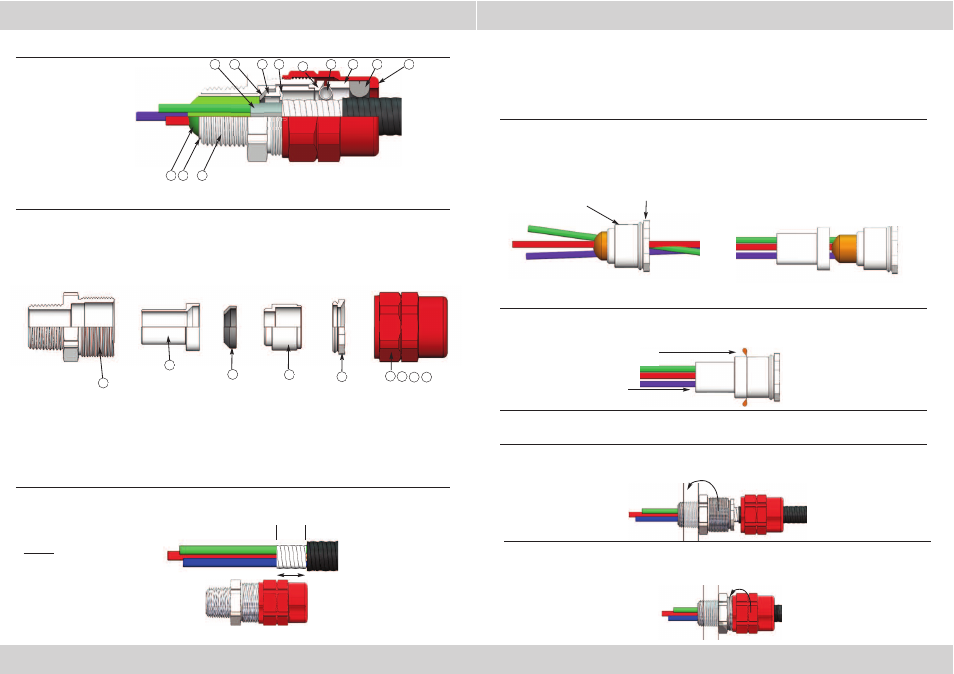

INSTALLATION INSTRUCTIONS FOR TMC2X CABLE CONNECTOR

DUBAI

• HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

www.cmp-products.com

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

1. Disasemble the connector by unscrewing the entry item (3) from the rest of the connector

and then unscrewing the spacer nut (8) from the entry component.

1

2

3

12

10

9

8

11

7

6

5

4

1. Compound

2. Compound Tube

3. Entry Item

4. Sealant Tape or Inner Jacket

5. Resin Dam (Optional)

6. Tube Spacer

7. End Stop

8. Spacer Nut

9. Grounding Spring

10. Angled Spacer

11. Jacket Seal

12. Outer Nut

NOTE: When the outer

jacket is at its

maximum, distance “L”

may have to be

increased by up to 10%.

3. Slide the outer nut assembly (9,10,11,12) down the cable. Pass the space nut (8) and tube

spacer (6) with nylon end stop (7) over the conductors until the end stop engages the end of the

cable armour. (If the nylon end stop will not pass over the conductors, then it should be discarded

as it is not needed.)

At this stage it should be possible to acces the tube spacer nut (8). If this is not possible, trim the

outer jacket up to the “L” +10% until access is possible.

8. Once the compound has cured, loosen the Tube Spacer Nut from the Entry Component. Screw

the Entry Component into the enclosure. Retighten the Tube Spacer Nut when the entry component

is fully tightened into the enclosure.

9. Finally, holding the cable central in the gland, tighten the Outer Nut to compress the Grounding

Spring to secure the armor and the seal to engage the cable jacket. Do not over tighten the

Outer Nut. The Entry Component and Outer Nut do not have to close face to face.

2. Strip back the jacket and armour to suit the equipment. Using the armor measure guide, expose

the armor further by stripping the cable jacket to distance “L”.

L

L = Distance from

groove to rear of nut.

DUBAI

• HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

CABLE CONNECTOR COMPONENTS

3

2

5

6

8

Remove and discard the resin dam (5). (This part is only needed when the connector is used

with the RapidEx resin system.)

4. Wearing the protective gloves supplied, thoroughly mix the two-part compound until the colour is

uniform. (The compound should not be mixed or applied at temperatures below 50°F/10°C.)

Seperate the cores of the conductor and pack the compound between and around the conductors

as shown below:

9

10 11 12

5. Bring the cores together again and pack

more compound around them to a length

and diameter sufficient to fill the

compound tube, ending in a taper.

6. Pass the compound tube (2) over the conductors until the stepped end is fully located with the

tube spacer (6). Pack more compound into place until the compound tube is fully filled.

7. Reinstall the cable assembly into the Entry Item (3) and tighten the Spacer Nut (8), finger-tight.

Leave for the compound to cure.

Remove surplus compound

Note: For instrumentation cable utilising shielded cable or industrial / overall drain wires see

installation guidance notes on the back page.

Ensure compound does

not overlap the tube

Tube Spacer

Spacer Nut