CMP E2U User Manual

Page 2

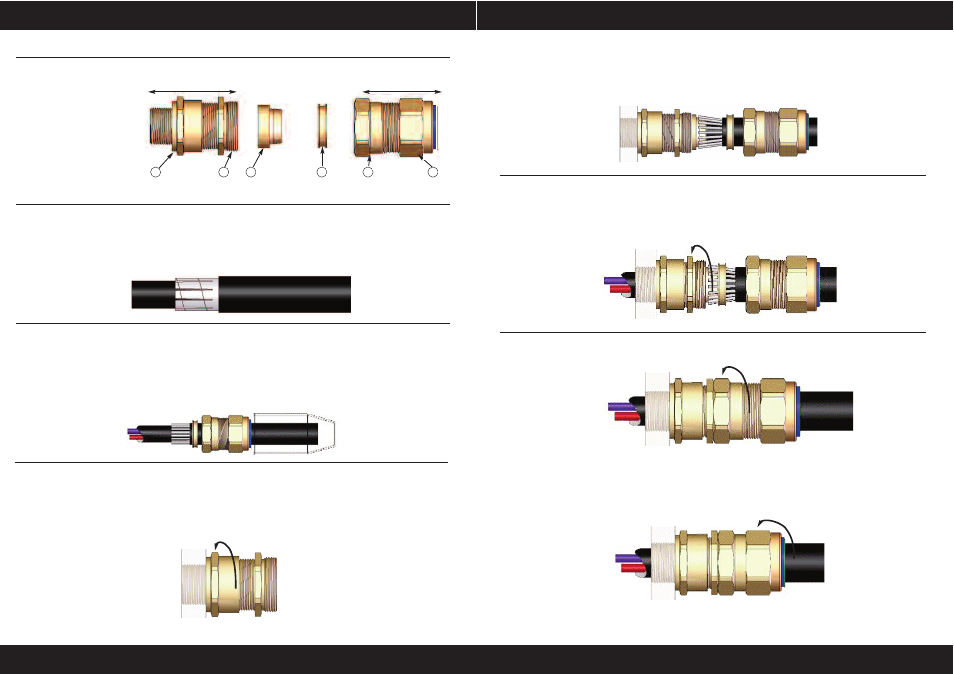

INSTALLATION INSTRUCTIONS FOR CMP CABLE GLAND TYPES “E”

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

DUBAI • HOUSTON • NEWCASTLE • SINGAPORE • SHANGHAI • PUSAN • PERTH

www.cmp-products.com

www.cmp-products.com

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING THE INSTALLATION

1. If required fit shroud over the cable outer sheath.

Prepare the cable by removing the cable outer sheath and the armour to suit the geometry of the

equipment. Remove a further 18mm (maximum) of outer sheath to expose the armour. If applicable

remove any tapes or wrappings to expose cable inner sheath. Tape armour should be further prepared

by cutting the tape into strips as shown below:

2. Separate the gland into two sub-assemblies “A & B”. Ensuring that the Outer Seal Nut (6) is relaxed,

pass sub-assembly “B” over the cable outer sheath and armour followed by the “AnyWay” clamping ring

(4).

Note: On maximum size cables the clamping ring may only pass over the armour.

3. Ensure that the inner seal is relaxed by slackening the Main Item (2). Secure sub-assembly “A” into

the equipment either by screwing the Entry Item (1) into a threaded hole or by securing it in a

clearance hole using a locknut as applicable.

4. Locate the Armour Cone (3) into its recess in the Main Item (2). (N.B. For E1U and E2U

variants, make sure the correct side of the cone is outermost - grooved for braid/tape armour and

stepped for SWA). Pass the cable through sub-assembly “A” until the armour engaged with the

cone. Spread the armour evenly around the cone.

5. While continuing to push the cable forward to maintain contact between the armour and the

cone, tighten the Main Item (2) by hand until heavy resistance is felt. (This is when the inner seal

makes contact with the cable inner sheath). Tighten a further full turn using a spanner.

NOTE: The earthing device on E2* type glands will automatically engage the lead sheath.

6. Hold the Main Item (2) with a spanner and tighten sub-assembly “B” onto sub-assembly “A”

using a spanner until all available threads are used.

7. Tighten the Outer Seal Nut (6) until it comes to an effective stop. This will occur when:-

A)

The Outer Seal Nut (6) has clearly engaged the cable and cannot be further tightened

without the use of excessive force by the installer.

B)

The Outer Seal Nut (6) is metal to metal with the body of the gland (5).

3

2

1

1. Entry Component

2. Main Item

3. Detachable Armour Cone

4. AnyWay Clamping Ring

5. Body

6. Outer Seal Nut

4

Sub Assembly A

Sub Assembly B

CABLE GLAND COMPONENTS - It is not necessary to dismantled the cable gland any further than illustrated below

6

5