BMR Suspension TAS003 User Manual

Page 4

4

(CONTINUED)

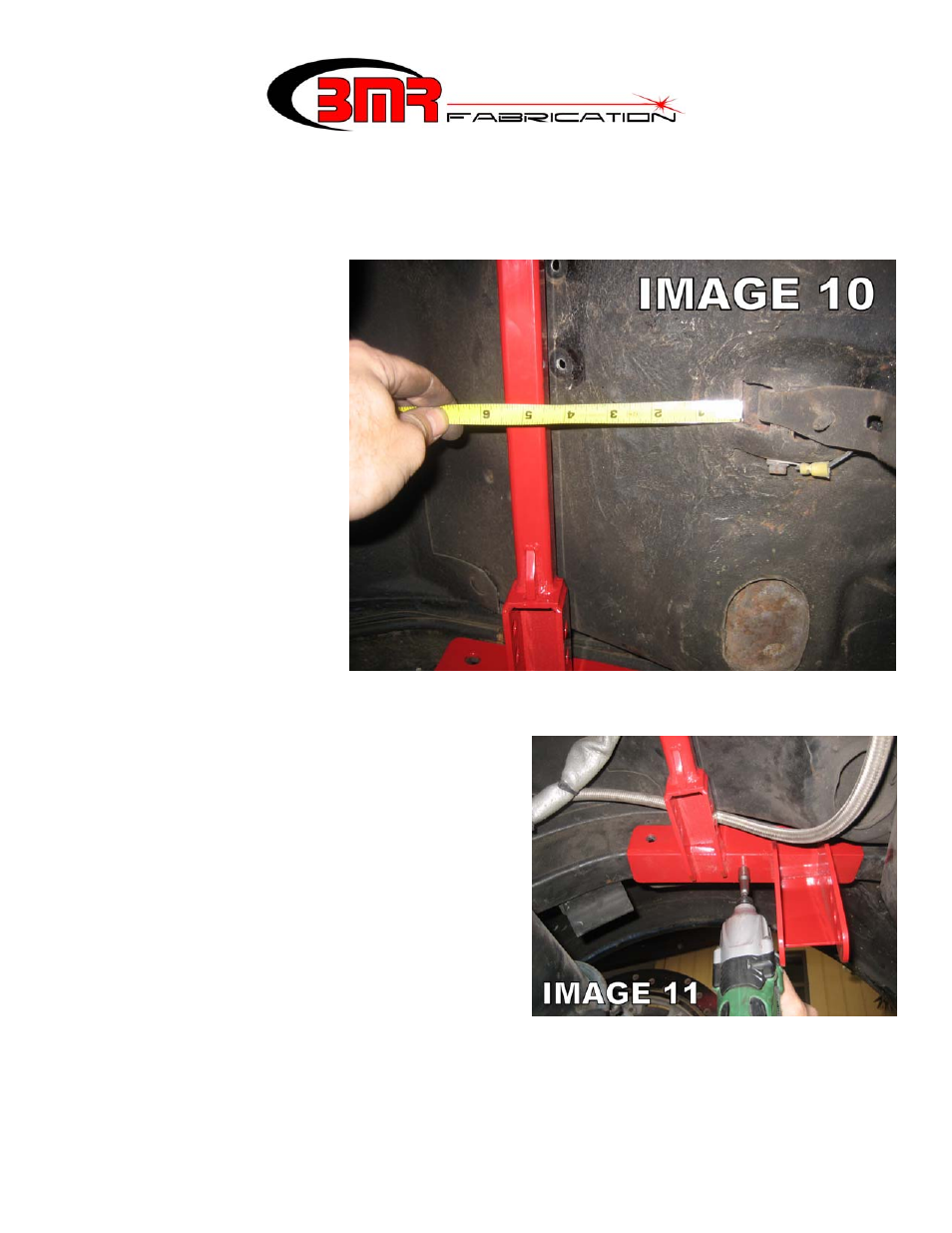

but the measurements should fall somewhere between 4-3/8” to 4-9/16”. Re-

position the cross-member until the reading from each strap mount relief is equal and

falls within the range listed above.

20. Once properly

positioned, locate the

provided sheet metal

screws in the

hardware pack. As

shown in Image 11,

screw the cross-

member into each

frame rail to hold it

into position for the

upcoming steps.

NOTE: the cross-

member should draw

up tight against the

frame rail. Any floor

pan deformations that

prevent the cross-

member from fitting

flush against the

frame rail should be

adjusted using a pry-bar or rubber mallet.

21. At this step the cross-member may be welded to the subframe or bolted. If bolting is

preferred, proceed to step 22. If welding is

preferred, remove the cross-member and prep

it for welding by grinding the powdercoat off

at the weld points. Remove all paint,

undercoating and scale from the weld area on

the subframe then re-install the cross-member.

Weld a full 2” bead vertically on each end of

the plate and at least 4 inches of weld

horizontally on each side. Wire brush and

paint the weld area with rust preventive paint.

Proceed to step 28.

22. If bolting the cross-member into place,

position the provided frame reinforcement

plate as shown in Image 12. Mark the frame

at the center of the slot using a grease pencil or paint marker.

23. Center punch the marks on the frame to provide a drill centerline.