BMR Suspension SFC006 User Manual

Heavy duty boxed subframe connectors

1

HEAVY DUTY BOXED SUBFRAME CONNECTORS

SFC006 – 1967-1969 Camaro and Firebird

Please read the following important information before proceeding with this installation.

• It is recommended to perform this installation on a 4 post service lift with the suspension loaded.

Two post lifts or floor jacks cannot be used because it is necessary to separate the body from the

frame during the installation.

•

This installation does not account for brake and fuel lines that may need relocation due to

interference.

Please have all the materials necessary to perform modifications to these items

before proceeding.

Tools required:

o

Pry-bar

o

Rubber mallet

o

MIG welder

o

Sawzall or Cut-off wheel

o

¾” wrench

o

¾” and 15/16” sockets

o

Drill with ½” bit

Installation:

1. Before raising the vehicle it is necessary

to remove the lower portion of the rear

seat and the front seats to gain access to

the floor pan area. The front seats unbolt

using a ½” or 9/16” socket depending on

the year the vehicle was manufactured.

The rear lower seat can be removed by

pushing in on the front of the seat and

lifting upward at the same time. There is

a seat retainer on both the driver’s side

and the passenger side lower seat that must be unfastened to lift the seat upward. Once released, remove

the seat and place aside.

2. Pull up the carpet and insulation from the rear foot well to gain access to this area.

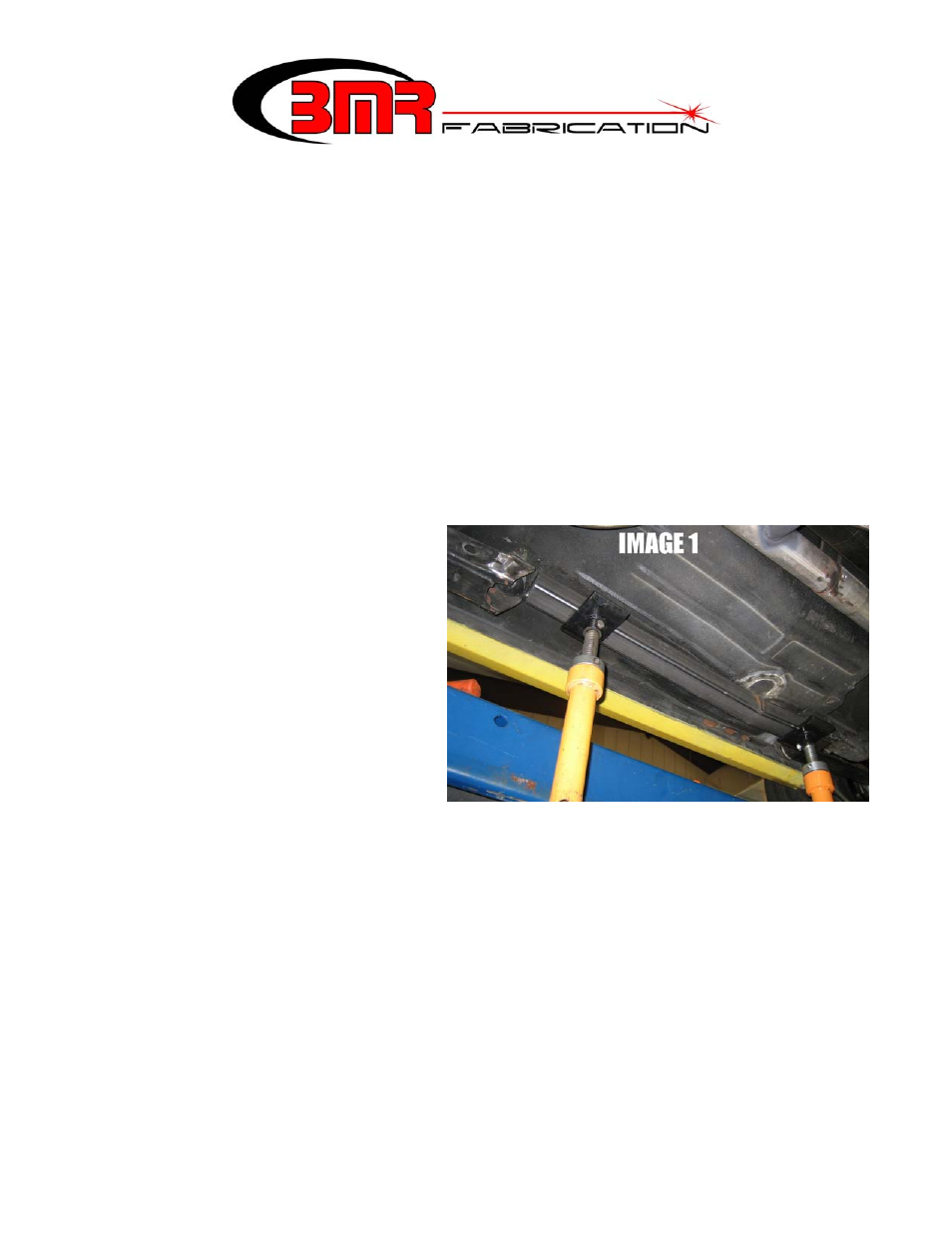

3. Lift the vehicle. Position one of the subframe connectors up against the floor as shown in Image 1. The

subframe connector should be centered to the front subframe and the rear subframe.

4. Once properly positioned, trace the subframe connector on the floor pan with a grease pencil or paint

marker. This will be your cut-line.

5. SEE NOTES BELOW BEFORE PROCEEDING: Using a Sawzall, body saw, or cut-off wheel carefully

cut on the inside of the lines and remove the cut portion.

NOTE: make your cuts smaller than needed, it is always easier to widen the hole with a second cut than to

make the hole too large and have a big gap to weld.