Applications, Installation installation manual, Space-heating applications- -recirculation – Takagi T-H3M-IN/OS User Manual

Page 29

29

Page

Installation

Installation Manual

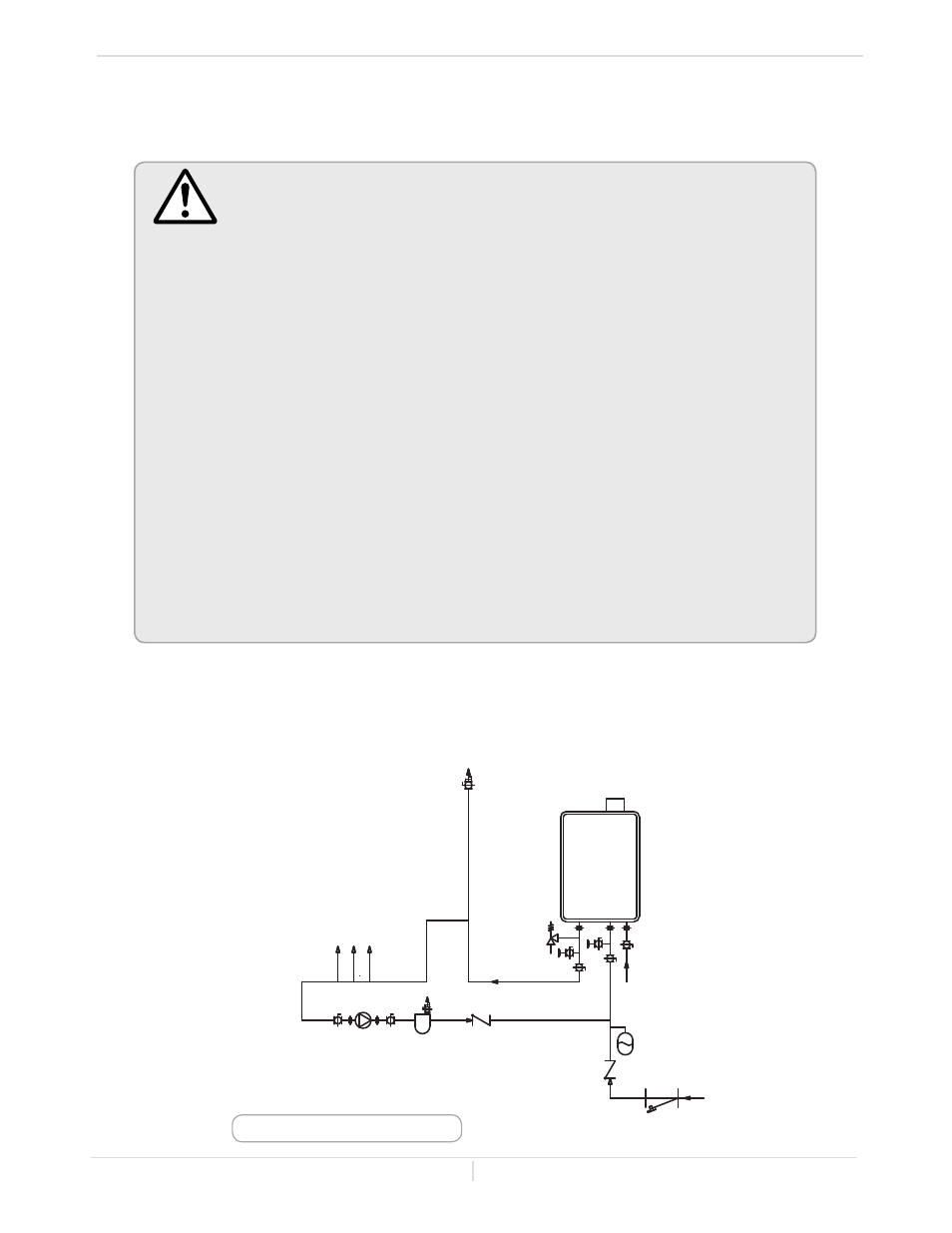

• In order to purge air in water pipes within a closed-loop system, an air vent

and air separator should be installed in the system. Required circulation

flow rates are labeled next to each application diagram. These flow rate

requirements must be followed

• Toxic chemicals used in boiler treatments such as alcohol, glycerol and glycol

groups must not be introduced into the system if the system incorporates an

open-loop potable water system

• The water heater can be used to supply potable water and space heating and

shall not be connected to any heating system or component(s) previously

used with non-potable water where any chemicals were added to the water

heating appliances

• When the system requires water for space heating at temperatures higher

than required for other uses, a means such as a mixing valve shall be installed

to temper the water for those other uses in order to reduce scald hazard

potential

• Water temperature over 125 °F (52 °C) can cause severe burns instantly or

death from scalding

• Chemicals such as diluted Glycol can be used for radiant floor, Hydro/fan coil

air or Baseboard heating only The diluted solution of glycol must contain

between 25 and 55 % of Glycol Be aware that in closed-loop glycol systems,

low pressure in the heat exchanger can cause low-temperature boiling,

resulting in excessive noise and damage to the water heater Consult with the

glycol maker for specifications prior to use

WARNING

S

Air vent

Hot water outlet to fixtures

Recirculation

pump

Air

separator

Check valve

Check valve

Y-Strainer

Cold water inlet

Expansion tank

Gas supply

Ball valves

Unions

Hot w

at

er ou

tle

t

Cold

w

at

er in

le

t

Gas in

le

t

APPLICATIONS

-Space-Heating Applications-

-Recirculation-

*The recirculation pump is to be controlled by:

-Dual-set aquastat (recommended w/timer)

*The recirculation pump is to provide no less than 2 GPM (7.5 L/min) and no more than 4 GPM (15 L/min) through

each activated unit in the system.

This is a concept drawing only