2 span (full scale) adjustment and calibration – Setra System Model 760 User Manual

Page 12

5.0 Calibration & Adjustment

5. 1 Checking & Zero Adjustment

After installation on a system, the Model 760 may require initial zero adjust-

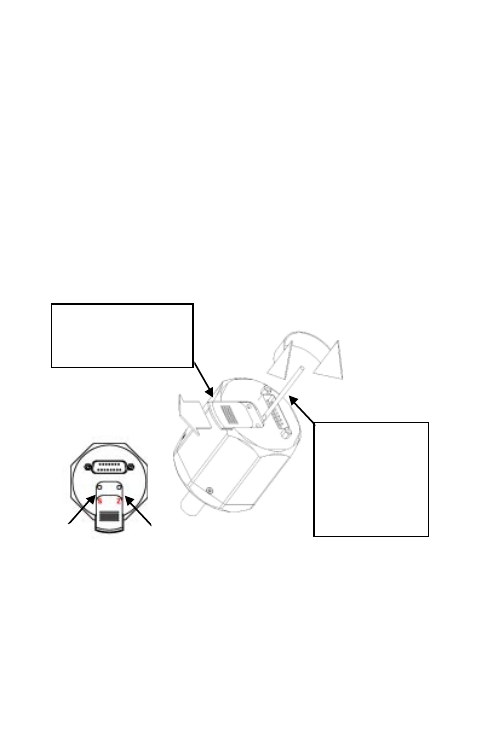

ment. Figure 9 shows the location of the zero adjustment potentiometer. Slide

open the black plastic insert to reveal two access holes. The access hole next

to the raised "Z" on the plastic cover identifies the Zero potentiometer.

Use an accurate digital voltmeter to view the signal output of the Model 760.

Adjust the signal output of the model 760 to be 0.001 to –0.001 mV. Make this

adjustment at a pressure at least 1/2 decade below the Model 760’s resolution;

e.g., for a 10 Torr FS unit the zero pressure should be less than 5E-4 Torr . For a

1000 Torr unit, a pressure less than 0.050 Torr is sufficient.

The Zero potentiometer is a multi–turn potentiometer providing very fine

adjustment of the zero over a +/- 500 mV range.

Figure 9 : Location of Calibration Adjustment Potentiometers

5. 2 Span (Full Scale) Adjustment and Calibration

The Zero adjustment is the only adjustment that should be made in the field.

Span (Full Scale) adjustments require a calibrated and certified reference

standard and should only be attempted by qualified personnel. Return the

Model 760 to Setra Systems for periodic calibration, Span (Full Scale)

Adjustment and Colibration adjustments and servicing.

9

Slide out plastic insert

to end stop to reveal

access holes to the zero

and span potentiometers.

Use a small flat

bladed screwdriver

to adjust the zero

(Z). Clockwise to

increase; Counter-

clockwise to

decrease signal.

SPAN

ZERO