3 configuration of the analog output signal type, 5 mechanical installation, 1 general guidelines – ROTRONIC HF8 User Manual

Page 12: Configuration of the analog output signal type, Mechanical installation, General guidelines, E-m-hf8-v2_10, 5mechanical installation

E-M-HF8-V2_10

Rotronic AG

Bassersdorf, Switzerland

Document code

Unit

HygroFlex HF8 Humidity Temperature

Transmitter: User Guide

Instruction Manual

Document Type

Page 12 of 35

Document title

© 2012; Rotronic AG E-M-HF8-V2_10

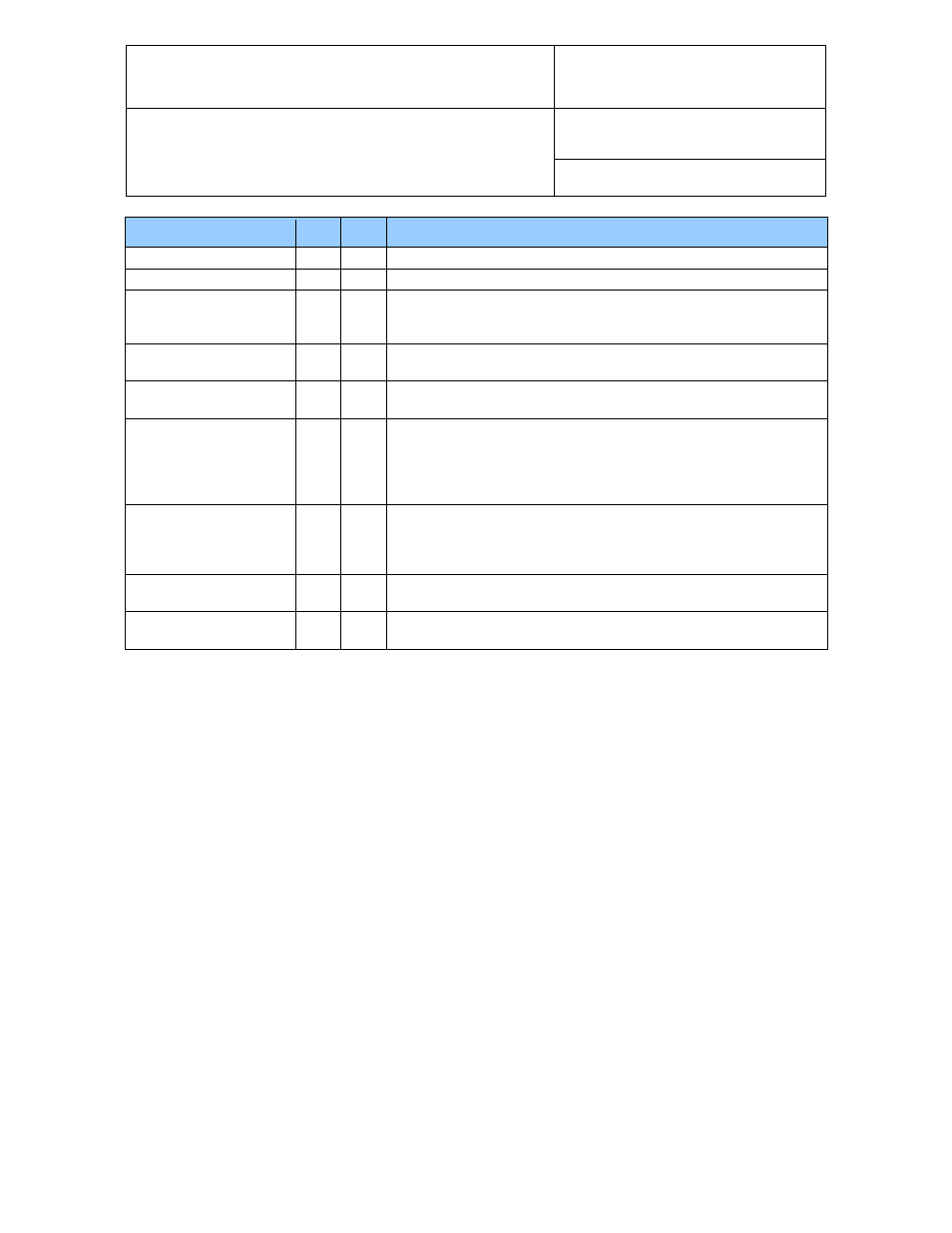

Function / Setting

HF8

HC2

Notes

Device protection

X

X

Individual to the HF8 and HC2 probe

RS-485 address

X

X

Individual to the HF8 and HC2 probe

Device Name

X

X

User defined description

The device name of the HC2 probe is not displayed by HW4 and is

replaced with the HF8 Input Name

Calculation

X

X

Psychrometric calculation

HF8 setting overrides HC2 probe setting

Simulator function

X

X

Generates fixed humidity and / or temperature value

When enabled, the HF8 settings override the HC2 probe settings

Unit system

X

X

The HF8 setting overrides HC2 probe setting. The HC2 probe

settings still apply when the probe is used alone

Make sure to use the same humidity symbol and the same

temperature unit for both the HF8 and probe.

Out-of-limits value alarm

X

X

The HF8 settings are independent from the HC2 probe settings.

The HC2 probe settings have no effect on the HF8 and out-of-limits

values defined at the probe level do not generate a HF8 alarm.

RH sensor test

X

The RH sensor is tested according to the time interval specified for

the probe (HW4 Device Manager)

Analog outputs

X

Parameter and scale

The HC2 probe settings have no effect on the HF8

4.3 Configuration of the analog output signal type

The type of analog output signals generated by the HF8 can be configured with the ROTRONIC HW4

software after connecting the HF8 with a service cable to a PC running HW4.

See document E-M-HW4v3-F2-015

5

Mechanical installation

5.1 General guidelines

Relative humidity is extremely dependent on temperature. Proper measurement of relative humidity requires

that the probe and its sensors be at exactly the temperature of the environment to be measured. Because of

this, the location where you choose to install the probe can have a significant effect on the performance of the

instrument. The following guidelines should guarantee good instrument performance:

a) Select a representative location: install the probe where humidity, temperature and pressure

conditions are representative of the environment to be measured.

b) Provide good air movement at the probe: air velocity of at least 200 ft/ minute (1 meter/second)

facilitates adaptation of the probe to changing temperature.

c) Avoid the following: (1) Close proximity of the probe to a heating element, a cooling coil, a cold or

hot wall, direct exposure to sun rays, etc. (2) Close proximity of the probe to a steam injector,

humidifier, direct exposure to precipitation, etc. (3) Unstable pressure conditions resulting from

excessive air turbulence.