ROTRONIC PF4 User Manual

ROTRONIC Accessories for electrical

12

.0

996

.0003

ROTRONIC AG, CH-8303 Bassersdorf

Tel. +41 44 838 11 44, www.rotronic.com

ROTRONIC Messgeräte GmbH, D-76275 Ettlingen

Tel. +49 7243 383 250, www.rotronic.de

ROTRONIC SARL, 56, F - 77183 Croissy Beaubourg

Tél. +33 1 60 95 07 10, www.rotronic.fr

ROTRONIC Italia srl

,

I- 20157 Milano

Tel. +39 2 39 00 71 90, www.rotronic.it

ROTRONIC Instruments (UK) Ltd, West Sussex RH10 9EE

Phone +44 1293 571000, www.rotronic.co.uk

ROTRONIC Instrument Corp, NY 11788, USA

Phone +1 631 427-3898, www.rotronic-usa.com

ROTRONIC Instruments Pte Ltd, Singapore 159836

Phone +65 6376 2107, www.rotronic.sg

ROTRONIC Shanghai Rep. Offi ce, Shanghai 200233, China

Phone +86 40 08162018, www.rotronic.cn

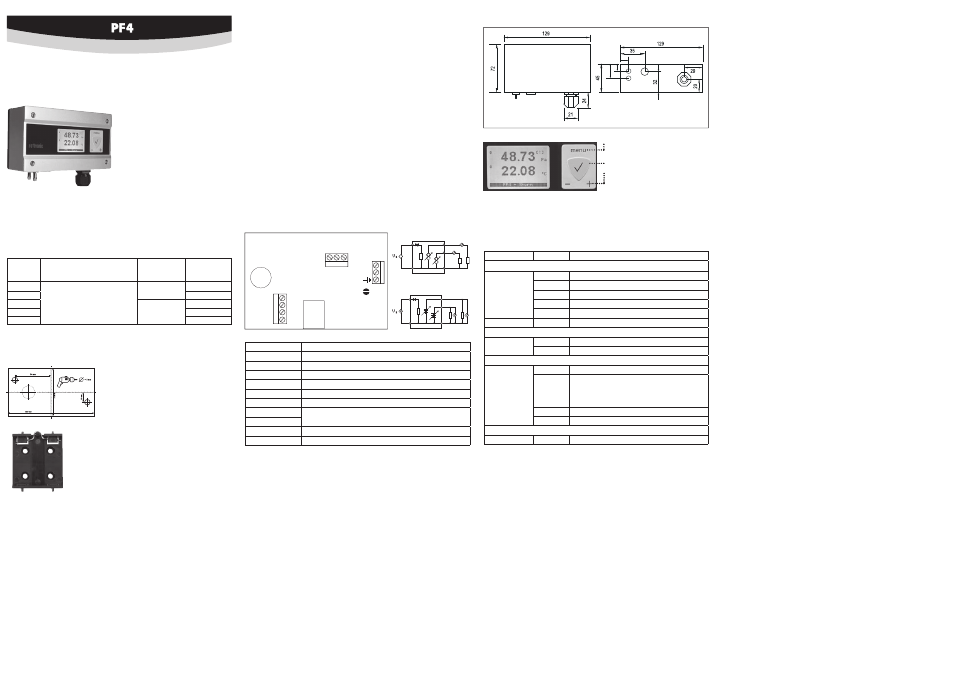

A

Terminal

Description

K2-1 V–

Power supply −

K2-2 V+

Power supply +

K2-3

Earth

K3-1 NC

Normally closed (relay not energized)

K3-2 COM

Common terminal

K3-3 NO

Normally open (relay energized)

K4-4 GND

GND

K4-3 GND

K4-2 OUT2

Analog temperature / humidity output +

K4-1 OUT1

Analog differential pressure output +

Terminal K2-3: Earth is usually connected to V–. If this is not wanted, the solder pad B5 on the

PCB must be opened.

Warning

Make sure that all settings have been made correctly before integrating and connecting the

transmitter in the network.

SHORT INSTRUCTION MANUAL

MENU button: open / close menu

ENTER button: select menu point

Menu navigation

Buttons + / - change value:

increase / decrease

Digital Differential Pressure Transmitter

Congratulations for the purchase of your new PF4

transmitter. Please read these short instructions

carefully before installing the device.

General Description

These short instructions are limited to a descrip-

tion of the main functions and installation of

the device. The detailed instruction manual can

be found on the internet at:

www.rotronic.com

Commissioning

The device was adjusted in our factory per the accompanying certifi cate and therefore does not

need to be checked or readjusted during installation. After installation the device must be zeroed

by connecting the two pressure connections and the absolute air pressure (QFE) of the environs

entered into the device.

Supply Voltage / Current Consumption

Type

Supply Voltage /

Current Consumption

Load

Output

PF431

15...40 VDC / 14... 28 VAC

<70 mA

(150 mA @ 15 VDC with Ethernet)

Max. 500

Ω

0...20 mA

PF432

4...20 mA

PF433

Min. 1000

Ω

0...1 V

PF434

0...5 V

PF435

0...10 V

Caution: Wrong supply voltages and excessively high loading of the outputs can

damage the transmitter.

Mounting with Drill Template

Drill the necessary holes using the drill template drawn

on the packaging. Then insert the plugs delivered with the

device and mount the transmitter with the screws.

Mounting on DIN Top-Hat Rail

The transmitter can be mounted directly on a TS35 DIN top-hat

rail with the AC5002 mounting kit (order separately). For this,

the DIN holders are screwed directly on to the pre-drilled holes

in the transmitter.

Specifi cations

Differential pressure measurement range: -25...+25 Pa / -50…+50 Pa

-100...+100 Pa / -250…+250 Pa

-500...+500 Pa

Measurement range:

-100...200 °C (depending on probe)

0...100 %rh

Range of application electronics

0...70 °C / 0…90 %rh

0...60 °C (with display)

Accuracy differential pressure:

±1.0 % full scale @23 °C ±3 K

Long-term stability sensor:

±0.3 %/year

Accuracy temperature:

Probe-dependent

Protection:

IP65 / IP40 (model with Ethernet)

Outputs:

0…1 V / 0…5 V / 0…10 V / 0…20 mA / 4…20 mA

Scale:

0…10 Pa / 0...25 Pa / -25...25 Pa / 0…50 Pa / -50...50 Pa

0…100 Pa / -100...100 Pa / 0…250 Pa / -250...250 Pa

0...500 Pa / -500...500 Pa

Interfaces:

Ethernet (option)

HW4 compatibility:

Version v3.2 / v3.4 (with HC2) and later

Relay switching capacity:

<50 VAC / <75 VDC / <1 A, confi gurable with HW4

Housing material:

ABS

Terminal Confi guration / Wiring Diagrams

The type is defi ned using the table Supply Voltage / Technology and then one of the following

wiring diagrams used:

Dimensions / Connections

Note

Unauthorized use of the menus can be blocked with the HW4 software.

The function for this is to be found in

HW4 Software > Device Manager > Display.

Main Menu Points

Main Menu

Submenu

Selection / Information

Device Settings

Units

Metric / English

Back Light

Key Press / On / Off

Pressure

Absolute air pressure

Value 1

DiffPress / Humi HC2 / Temp HC2 / Calc / None

Value 2

DiffPress / Humi HC2 / Temp HC2 / Calc / None

Value 3

DiffPress / Humi HC2 / Temp HC2 / Calc / None

Device Information

Version

Firmware version

Serial Nbr

Serial number

Differential Pressure

Unit

Unit of measured value

Filter

Pa / inH2O / mpsi / mbar / mmHg / mmH2O / Torr / g/m2

0

τ63 = 0 s

7

τ63 = 32 s

Adjust

Sensor adjustment

Zero Adjust

Zero adjustment

Probe information (PF4 with HC2 connector)

SensorType HC2 / Analog In

Scaling / Adjustment / Firmware Update

The following settings can be changed using the HW4 software and a link to your computer per

AC3006 service cable:

• output scale

• adjustment

• fi rmware update

IMPORTANT

The PF4 can just be adjustet with AC3006 cable and external power supply.

You can fi nd a detailed description in the manual that you can download from our web site at

www.rotronic.com.

Periodic Calibration of the Transmitter

Both the differential pressure sensor and the corresponding electronics are very stable and

do not normally need to be changed or calibrated after factory calibration. For maximum

accuracy we recommend regular calibration of the device.

Caution

Any movement of the sensor or the pipes during calibration and adjustment, will result in

deviated values.

Ethernet

Current Output

Voltage Output

=

~

V+

GND

GND

OUT1

OUT2

V+

GND

GND

OUT1

OUT2

1

2

3

K 2

V –

V +

K4

GND

GND

OUT2

OUT1

4

3

2

1

OUT 1 = Pa

OUT 2 = %rh / °C / °F

1 2 3

NO

NC

CO

M

K 3

B5

26

12.5

20.5

26

12.5

20.5