ROTRONIC HF8 User Manual

ROTRONIC Accessories for electrical

12

.0

90

2.

0003

ROTRONIC AG, CH-8303 Bassersdorf

Tel. +41 44 838 11 44, www.rotronic.com

ROTRONIC Messgeräte GmbH, D-76275 Ettlingen

Tel. +49 7243 383 250, www.rotronic.de

ROTRONIC SARL, 56, F - 77183 Croissy Beaubourg

Tél. +33 1 60 95 07 10, www.rotronic.fr

ROTRONIC Italia srl

,

I- 20157 Milano

Tel. +39 2 39 00 71 90, www.rotronic.it

ROTRONIC Instruments (UK) Ltd, West Sussex RH10 9EE

Phone +44 1293 571000, www.rotronic.co.uk

ROTRONIC Instrument Corp, NY 11788, USA

Phone +1 631 427-3898, www.rotronic-usa.com

ROTRONIC South East Asia Pte Ltd, Singapore 339156

Phone +65 6294 6065, www.rotronic.com.sg

ROTRONIC Shanghai Rep. Office, Shanghai 200233, China

Phone +86 40 08162018, www.rotronic.cn

A

Digital transmitter for humidity & temperature

Congratulations on your purchase of the new state-of-the-art HygroFlex8-series transmitter. Please

read these short instructions carefully before installing the device.

General description

The HygroFlex8-series devices are universal transmitters for transmission of humidity and tempera-

ture measurements. Compatible with all interchangeable HC2 probes. These short instructions are

limited to a description of the main functions and installation of the device. The detailed instruction

manual can be found on the internet at:

www.rotronic.com

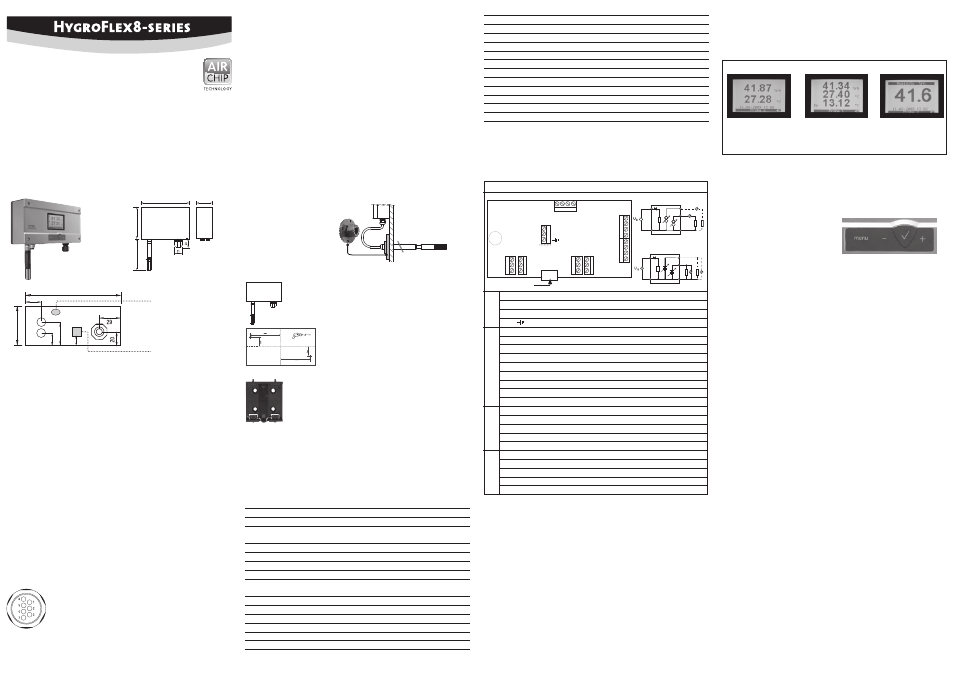

Dimensions / Connections

Wall version

Measured Parameters

HygroClip2 probe:

Humidity and temperature. The HC2 probes measure relative humidity with a ROTRONIC Hygromer

®

IN1 capacitive sensor and temperature with a Pt100 RTD.

Analog probe (general):

Any parameter measured by the probe. The parameter unit must be specified with the HW4 software

(Device Manager). Analog pressure probe: the unit used for barometric pressure is set with the

HW4 software > Device Manager > Unit System.

Probe inputs

The HF8 has two probe inputs. Using the HW4 software (Device Manager), each probe input can

be configured to accept one of the following:

HygroClip2 humidity-temperature digital probe:

Both inputs can be configured to read and display digital signal of a HygroClip2 probe.

1-channel analog probe (general):

To be compatible with the HF8 the analog probe must meet the following requirements: supply

voltage: max. 5 VDC, current consumption: max. 10 mA, output signal: 0 to max. 3.3 VDC. The HF8

uses a 12-bit A/D converter to digitize the probe analog signal and can be configured to measure

practically any parameter.

Analog pressure probe:

This is a special case of analog probe and is subject to the same compatibility requirements. When

analog pressure probe is selected, the HF8 automatically uses the signal from the probe to calculate

any humidity parameter that requires barometric pressure as an input value (example: mixing ratio).

AC5005 Mounting flange

for 15 mm probe

Service interface

Digital connection

Mounting the wall version

Alignment

Mount the transmitter so that the probe points down.

Mounting variant 1

Drill the necessary holes using the drill template drawn on the

packaging. Then insert the plugs delivered with the device and

mount the transmitter with the screws.

Mounting variant 2

If there is a TS35 DIN top-hat rail available, the transmitter can be

clipped on to the top-hat rail directly with the help of the mounting

kit AC5002 (available as optional extra). For this, the DIN holders

(a kit has two holders and eight screws) are screwed directly on to

the predrilled holes in the transmitter.

Electrical installation

Power supply

a)

HF831 - HF835: 15 to 40 VDC or 12 to 28 VAC

b)

HF841 - HF845 (galvanic separated): 9 to 36 VDC or 7 to 24 VAC

c)

HF857: Power over Ethernet (PoE) or 12 to 28 VAC

d)

HF861 - HF865: 85 to 265 VAC

Note: depending on the type of output signal, the HF8 will operate with the following

minimum voltage

0…1 V outputs

5 VDC or 5 VAC

0…5 V outputs

10 VDC or 8 VAC

0…20 mA or 4 …20 mA outputs

6 VDC or 5 VAC with 0 ohm load

15 VDC or 12 VAC with 500 ohm load

Typical maximum current consumption

Model with 4 analog outputs

150 mA

Model with 4 relay contacts

150 mA

Model with Ethernet (TCP/IP) interface

300 mA

Supply voltage / Technology

Type

Supply voltage V+

Load

Output

HF831

15…40 VDC / 12…28 VAC

Max 500

Ω

0...20 mA

HF832

15…40 VDC / 12…28 VAC

Max 500

Ω

4...20 mA

HF833

15…40 VDC / 12…28 VAC

Min 1000

Ω

0...1 V

HF834

15…40 VDC / 12…28 VAC

Min 1000

Ω

0...5 V

HF835

15…40 VDC / 12…28 VAC

Min 1000

Ω

0...10 V

Type

Supply voltage V+

Load

Output

HF841

9…36 VDC / 7…24 VAC

Max 500

Ω

0...20 mA

HF842

9…36 VDC / 7…24 VAC

Max 500

Ω

4...20 mA

HF843

9…36 VDC / 7…24 VAC

Min 1000

Ω

0...1 V

HF844

9…36 VDC / 7…24 VAC

Min 1000

Ω

0...5 V

HF845

9…36 VDC / 7…24 VAC

Min 1000

Ω

0...10 V

HF857

Power over Ethernet (PoE)

Digital Output

HF861

85...265VAC

Max 500

Ω

0...20 mA

HF862

85...265VAC

Max 500

Ω

4...20 mA

HF863

85...265VAC

Min 1000

Ω

0...1 V

HF864

85...265VAC

Min 1000

Ω

0...5 V

HF865

85...265VAC

Min 1000

Ω

0...10 V

Caution:

Wrong supply voltages and excessively high loading of the outputs can

damage the transmitter.

Terminal configuration / Connection diagrams

The type is defined using the table Supply voltage / Technology to then use the following connec-

tion diagrams:

Terminal block diagram (all HF8 models)

Terminal Block K6 Description

K6-1: –

Power supply: VDC (-) or VAC (neutral)

K6-2: +

Power supply: VDC (+) or VAC (Phase)

K6-3:

Protective ground (see note below)

Terminal Blocks K1 and K2

Description

Standard output

K1-1: GND

Output signal 1 (–)

K1-2: GND

Output signal 2 (–)

K1-3: GND

Output signal 3 (–)

K1-4: GND

Output signal 4 (–)

K2-1: OUT 1

Output signal 1 (+)

Humidity*

K2-2: OUT 2

Output signal 2 (+)

Temperature**

K2-3: OUT 3

Output signal 3 (+)

Humidity*

K2-4: OUT 4

Output signal 4 (+)

Temperature**

Terminal Block K3 (RS-485)

Description

K3-1: V+

VDC (+), when HF8 is powered from RS-485 data cable

K3-2: GND

VDC (-), when HF8 is powered from RS-485 data cable

K3-3: D+

RS-485 +

K3-4: D–

RS-485 –

Relay

1 2 3 4

Terminal Block

K7

K8

K4

K5

NC: Normally closed (relay not energized)

K7-1

K8-1

K4-1

K5-1

COM: Common

K7-2

K8-2

K4-2

K5-2

NO: Normally open (relay not energized)

K7-3

K8-3

K4-3

K5-3

* For humidity and calculated value output settings:

OUT2/4 = calculated value, OUT1/3 = humidity

** For temperature and calculated value output settings:

OUT1/3 = calculated value, OUT2/4 = temperature

Terminal K6-3: Protective ground is usually connected to GND. If this is not wanted, a link on

the PCB (B2) must be removed.

Terminals K3 (RS-485): Terminals K3-1 and K3-2 can be used to feed the device (multi-point

connection). Several RS-485 devices can be operated with a strong 15 VDC power supply unit. In

this case the supply voltage at K6-1 to K6-3 is not used.

Warning: Make sure that all settings have been made correctly before integrating and connecting

the transmitters in the network.

Programming

The basic settings of the devices are made in the factory according to your order. The transmit-

ters are adjusted in the factory and therefore do not need to be checked and readjusted during

installation. The devices can be started immediately after installation.

SHORT iNSTRuCTiON MANuAL

Current output

Voltage output

Rel

ay

Digit

al

Analog

102

192

85

52

=

~

K6-2:

DC+/AC L

K6-1:

DC −/AC N

K1: GND

K2: OUT2...4

K2: OUT1

K1: GND

K2: OUT2...4

K2: OUT1

K6-2:

DC+/AC L

K6-1:

DC −/AC N

1) RXD (UART digital probe)

2) GND (digital and power)

3) V+: digital probes: 3.3 VDC nominal, analog probes: max. 5.0 VDC, 10 mA

4) AGND (analog ground)

5) Not used

6) One-channel analog probe signal: +0.0 to 3.3 VDC

7) TXD (UART digital probe)

Pin-Out Diagram

Mechanical installation

General recommendations

Relative humidity is extremely temperature-dependent. In order to measure it exactly, the probe and

sensors must be set exactly on the temperature level of the environment that is to be measured.

The installation site can therefore have a significant influence on the performance of the device.

Follow the guidelines below to ensure optimum performance:

a) Select a representative installation site: Install the probe at a point where the humidity, tempe-

rature and pressure conditions are representative for the environment that is to be measured.

b) Make sure there is sufficient air movement around the probe: An air flow of at least 1 meter/

second accelerates and facilitates adjustment of the probe to changing temperatures.

c) Avoid:

1. Probe too close to heating elements, cooling coils, cold or hot walls, direct sunlight, etc.

2. Probe too close to steam, injectors, humidifiers or direct precipitation.

3. Unstable pressure conditions with high air turbulence.

d) Insert the probe as far as possible into the environment that is to be measured.

e) Avoid accumulation of condensation at the contact wires of the sensor. Install the probe so

that the tip points down. If that is not possible, install it in horizontal position.

Mounting with separated probe

To avoid measurement errors, at least 200 mm of the probe should be inserted into the environ-

ment that is to be measured. If necessary, use the mounting flange AC5005 to install the probe.

Pow

er

Sup

ply

Display modes

The LC display has a backlight which can be set to be on all the time or whenever a key is pressed.

The backlight can also be disabled.

Using the HF8 Menu > Device Settings > Display Settings, the display mode can be changed as

shown below:

Standard

3-line display

Large

%RH

Temperature

Date and time

%RH

Temperature

Calculated parameter

No date and time

Both the parameter and

probe can be changed

with the UP arrow key or

the DOWN arrow key

The display can also be configured to show a trend indicator on each line:

▲

increasing value ▼ decreasing value

In the event of an alarm the symbol

[ ! ] appears to the right of the value.

The bottom of the display shows the date and time as well as which probe is currently selected.

Keypad

unit system

Press the MENU key and select Device Settings > Local Settings > Unit Sys. Press ENTER to activate

the Unit Sys menu item, use the [+] or [-] key to change the unit system. Press ENTER to confirm

and press MENU to exit.

The HW4 software can also be used to change the unit system.

Date and time

Press the MENU key and select Device Settings > Date or Time. Press ENTER to activate either

the Date or the Time menu item. Use the [+] or [-] key to change the Date or the Time. After each

change, the cursor moves to the right. When done, press ENTER to confirm and press MENU to exit.

To change either the date or the time format, Press the MENU key and select Device Settings >

Local Settings > Date Fmt or Time Fmt. Press ENTER to activate either the Date Fmt or the Time Fmt

menu item, use the [+] or [-] key to change the Date or the Time format. When done, press ENTER

to confirm and press MENU to exit.

The HW4 software can also be used to set the clock of the HF8 to the PC date and time.

Select the calculated parameter for a probe input

The calculated parameter is available only when the input is set for a digital HygroClip 2 probe.

Press the MENU key and select Device Settings > Input 1 or Input 2 > Calc. Press ENTER to activate

the Calc sub-menu, use the [+] or [-] key to select the calculated parameter. Press ENTER to confirm

and press MENU to exit.

192

52

16

31

22.3

39.5

MENu

Activates the internal menu. Press this key

again to go back to the previous menu or to

exit the menu.

ENTER ✔

• When the menu is active, use to confirm the

selection of a menu item, effect a change of

settings and confirm any change.

• In the HF8 Standard Mode, use to capture the

current %RH and temperature data to one of

8 data bins.

uP / DOWN + / –

• Changes either the probe or the parameter

being displayed (including the delta probe).

• When the menu is active, use to navigate the

menu, make a selection or change a value.

K 3

V+

GN

D

485+

485

–

1

2

3

4

K 1

K 2

GND

GND

GND

GND

OUT1

OUT2

OUT3

OUT4

1

2

3

4

1

2

3

4

K 4

NO

COM

NC

3

2

1

K 5

NO

COM

NC

3

2

1

K 7

NO

COM

NC

K8

NO

COM

NC

3

2

1

3

2

1

1

2

3

K6

DC–/AC N

DC+/AC L

B2

• •

digital in/output