Mechanical mounting, Pitch and roll conventions, 3 mechanical mounting – PNI SeaTRAX User Manual

Page 14

PNI Sensor Corporation

DOC#1018154 r02

SeaTRAX User Manual

Page 9

4.3

Mechanical Mounting

For the SeaTRAX, the full-radius cut-outs along the long sides are intended for test fixturing

and not as the mechanical mount in the user’s system. PNI recommends securing the long

edge of the PCB to a shelf or lip in the user’s system using an adhesive. Ideally the

SeaTRAX also would be fully potted in the user’s system to reduce or eliminate shock and

vibration effects. Refer to Section 3.2 for dimensions, hole locations, and the reference frame

orientation.

Note: Ensure that when attaching the SeaTRAX to the host system, the mounting method does not

introduce stresses on the board, as this can affect the performance of the accelerometer, and

therefore also negatively affect heading accuracy.

4.3.1

Pitch and Roll Conventions

The SeaTRAX uses a MEMS accelerometer to measure the tilt angle of the heading

sensor. This data is output as pitch and roll data, and is also used in conjunction with the

magnetometers to provide a tilt-compensated heading reading.

The SeaTRAX utilizes Euler angles as the method for determining accurate orientation.

This method is the same used in aircraft orientation where the outputs are heading (also

called yaw or azimuth), pitch and roll. When using Euler angles, roll is defined as the

angle rotated around an axis through the center of the fuselage while pitch is rotation

around an axis through the center of the wings. These two rotations are independent of

each other since the rotation axes rotate with the plane body.

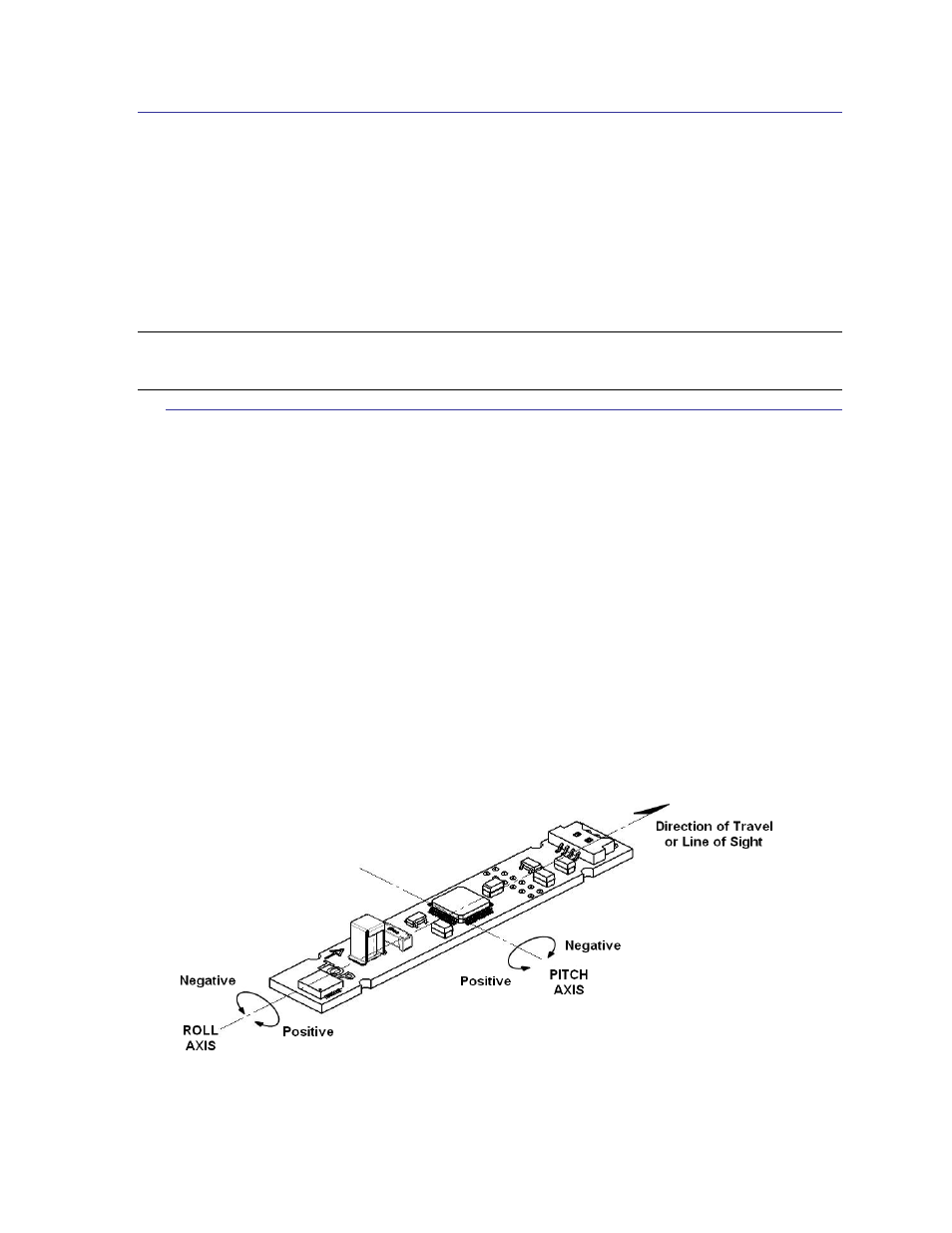

As shown in Figure 4-1, for the SeaTRAX a positive pitch is when the front edge of the

board is rotated upward and a positive roll is when the right edge of the board is rotated

downward.

Figure 4-1: Positive & Negative Roll and Pitch Definition