NORD Drivesystems BU0710 User Manual

Page 29

6 Fault clearance

BU 0710 GB

29

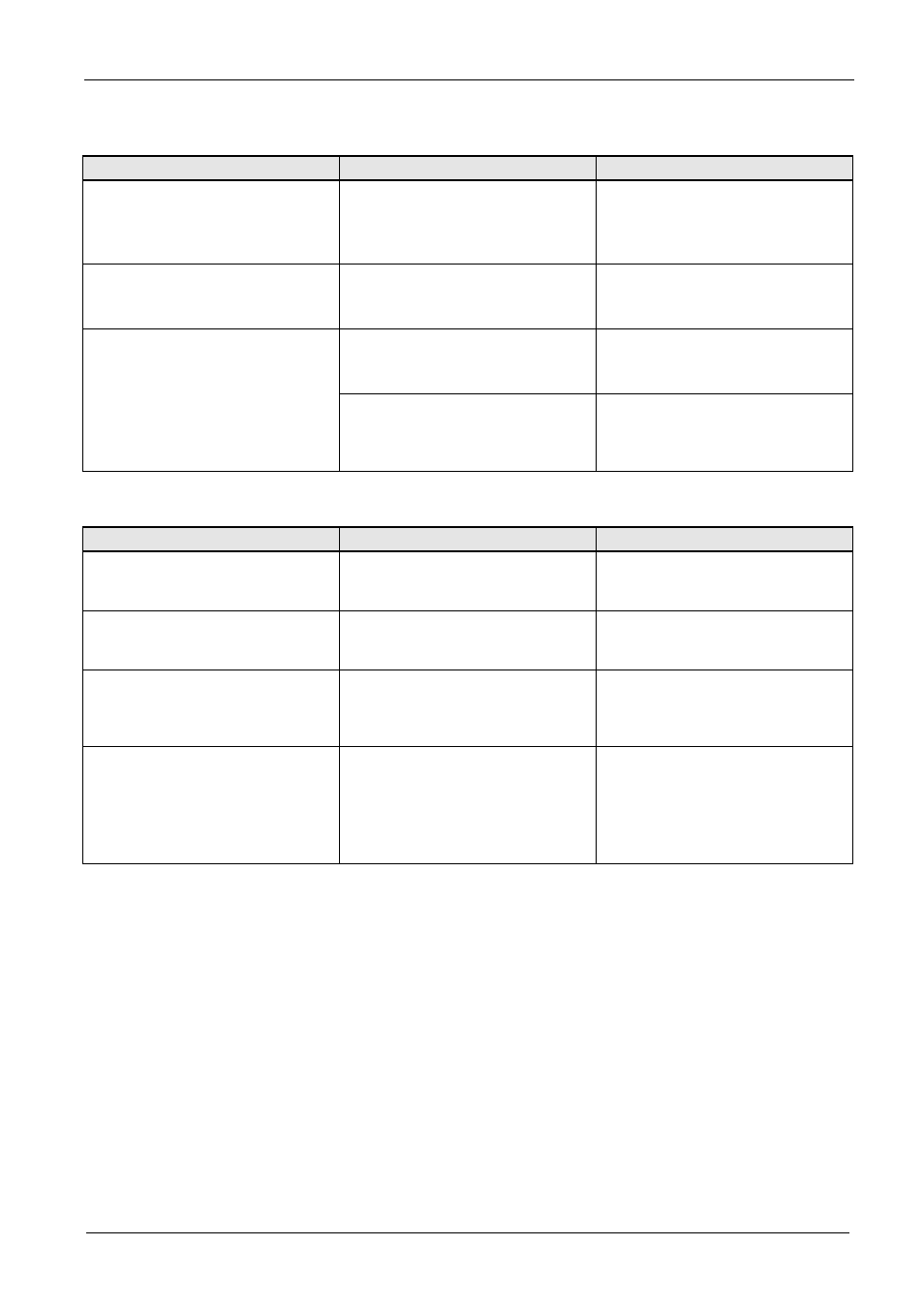

3. Typical error sources in position control with incremental position recognition (without absolute

encoder)

Symptom

Additional checking

Possible cause

Reference point error

• Reference point tracking

completed but failed

• Encoder lacks zero track, or

encoder is defective

Drive drifts away from desired

position

• Encoder cable affected by

interference pulses

Fault occurs even at low speed

(n < 1000 1/min))

• Encoder cable affected by

interference pulses

No repetitive accuracy when

moving into identical positions

several times

Fault occurs at high speed only

(n > 1000 1/min)

• Number of graduation marks

too high considering the length

of encoder cable / the cable

type (pulse frequency too high)

4. Typical error sources in position control with absolute encoder

Symptom

Additional checking

Possible causes

The same actual position value is

signalled over and over again and

remains steady afterwards

• Encoder connection is not

correct

Current position is displayed as an

erratic ("jumping") value although

the shaft does not move

• Encoder cables are affected by

interference pulses

Recognition function supplies

varying information on the same

position; sometimes the axle

seems to jump to and fro.

Is there any mechanical

irregularity?

• Axle is tight, getting jammed, or

does not move smoothly for

any other reason

Position value is not in accordance

with amount of encoder rotation or

is erratic => shaft encoder is

defective

Check absolute encoder

(detach it, set multiplication and

demultiplication parameters to 1,

turn encoder by hand: the position

indicated must be in accordance

with the encoder revolutions)

• Encoder

defective