6 operating status messages and led displays – NORD Drivesystems BU0240 User Manual

Page 35

6 Status messages

BU 0240 GB

35

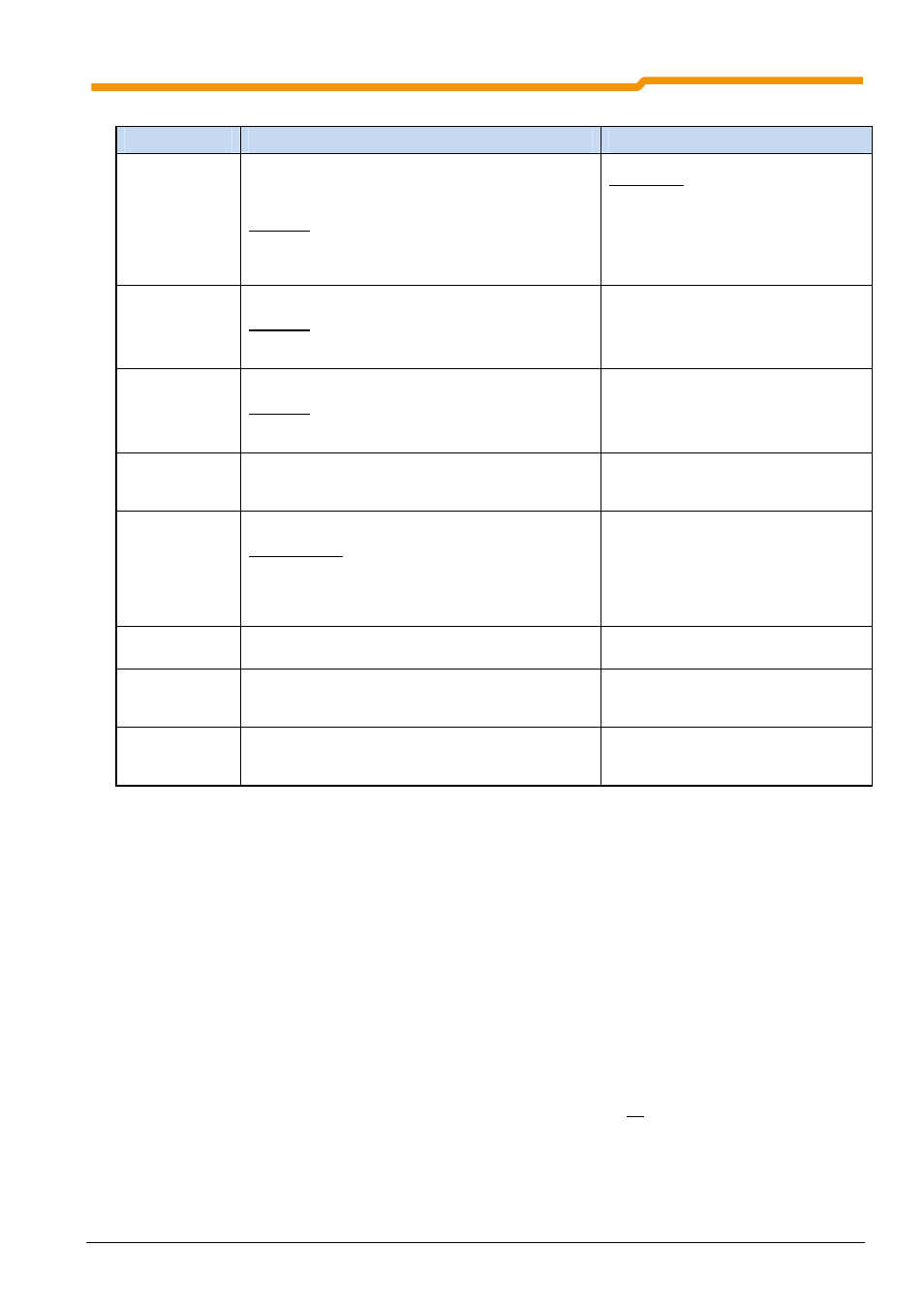

Parameter list - inverter information (selection)

Parameter

Description

Settings / functions (selection)

P700

Current

operating status

Display of current messages for the actual operating

status of the frequency inverter such as errors,

warnings or the cause of a switch-on block.

Selection:

Current error (P700, Array -01)

Current warning (P700, Array -02)

Reason for switch-on block (P700, Array -03)

Error group:

1 / 2 = Overtemperature of inverter / motor

3 / 4 = Overcurrent error

5 = Overvoltage error

16 = Motor phase monitoring

19…= Parameter identification error

P701

Last error

Displays the last 5 frequency inverter errors.

Selection:

Last error (P701, Array -01)

Second to last error (P701, Array -02)

See P700

P707

Software version

Displays the firmware version / Inverter revision

Selection:

Software version (P707, Array -01)

Revision (P707, Array -02)

P708

Digital input

status

Shows the switching status of the digital inputs.

Bit 0 = DIN 1

Bit 1 = DIN 2

…

P709

Analog input

voltage

Displays the measured analog input value.

Input selection:

Poti P1 (P400, Array -01)

Poti P2 (P400, Array -02)

DIN 2 (P400, Array -06)

DIN 3 (P400, Array -07)

P719

Actual current

Displays the actual output current.

P740

Process data

Bus In

Displays the actual control word and the setpoints.

[-01] = STW (Source P509)

[-02…-04] SW 1…3 (Source P510[-01]

[-11…-13] SW 1…3 (Source P510[-02]

P749

DIP switch status

Displays the current DIP switch setting.

Bit 0 = DIP switch 1

Bit 1 = DIP switch 2

…

6 Operating status messages and LED displays

The frequency inverter generates operating status messages. These messages (warnings, errors, switching

statuses, measurement data) can be displayed with parameterisation tools (e.g. ParameterBox) (Parameter

group P7xx).

To a limited extent, the messages are also indicated via the diagnostic and status LEDs.

Error messages

Errors cause the frequency inverters to switch off, in order to prevent a device fault.

The following options are available to reset a fault (acknowledge):

1. Switching the mains off and on again,

2. By an appropriately programmed digital input (P420 = Function 12),

3. By switching of the “enable” on the frequency inverter to Low (if no digital input is programmed for

acknowledgement),

4. By Bus acknowledgement or

5. by P506, the automatic error acknowledgement.

An error message can only be acknowledged if its direct cause is no longer present.