NORD Drivesystems B1904 User Manual

Page 20

Operating and Installation Instructions FDB (Getriebebau NORD)

Version 08.2011

Page

20

of 23

Holding brake:

+ at least every two years

+ according to specifications made by the customer

+ use shorter intervals in case of frequent emergency stops

Furthermore, check the rotor size s after a number of re-adjustments of the air gap a (see

5.1.3). A suitable control interval results from the relation of the difference s

neu

– s

min

to

difference a

nenn

– a

max

considering the respective tolerances.

5.1.3 Maintenance

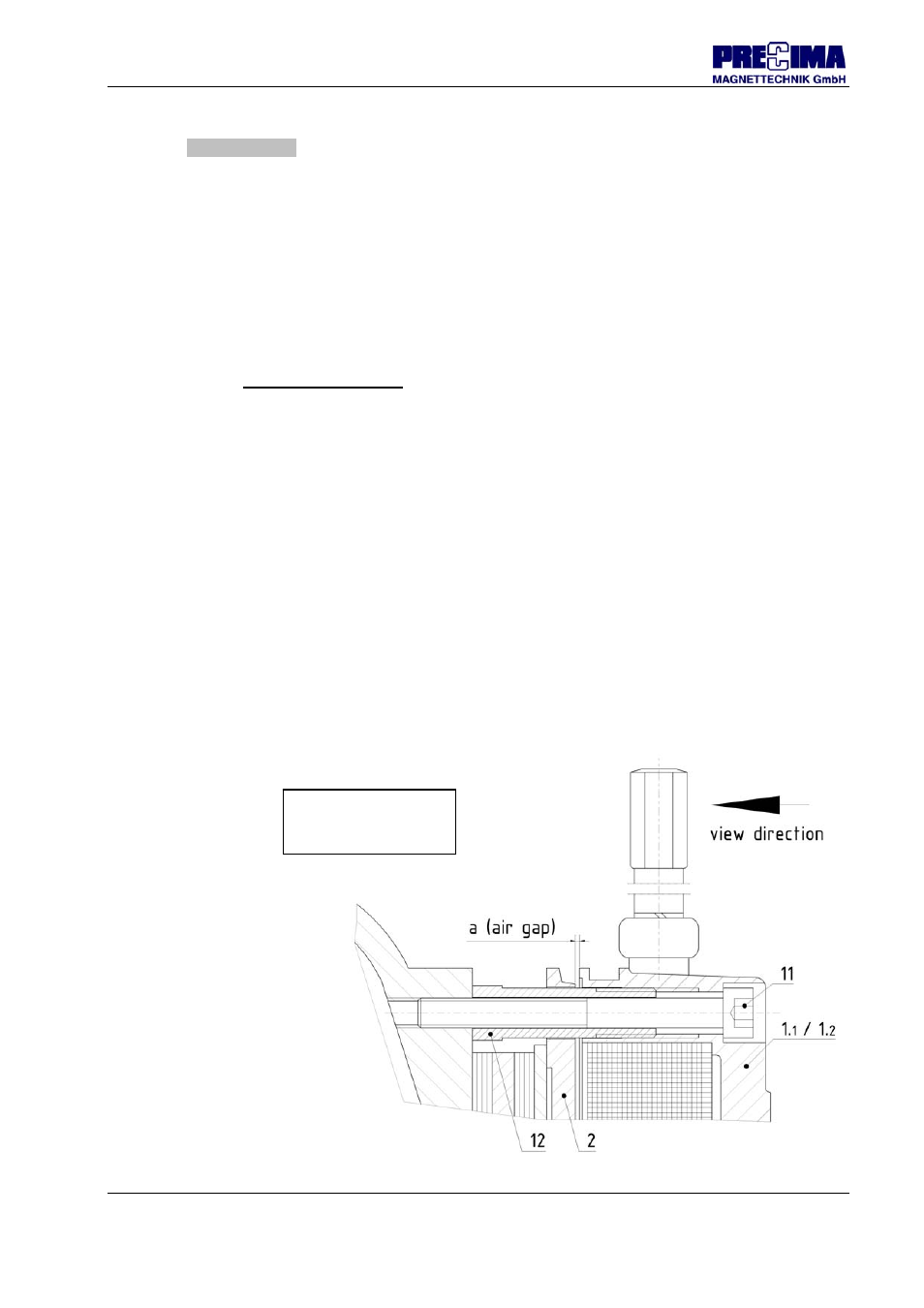

5.1.3.1 Readjusting the air gap (illustration 5.1)

The spring-applied brake is virtually maintenance-free. However, when the maximum air gap

stated under 3.2.2.4 is reached, a re-adjustment (new adjustment) of the air gap a will be

required for the safe operation of the brake. The functional capability of the brake which may in

certain cases go beyond the maximum air gap does not change the aforesaid requirement: “a

proper use” will no longer exist in such a case

. In this case, functional capability and safety

function of the brake will be compromised with a further increase in wear.

How to proceed when readjusting the air gap:

- Viewing in direction of the brake (see illustration 5.1) loosen the fastening screws (item 11)

by turning them half a rotation counter-clockwise.

- Turn the hollow screws (item 12) into the magnet body by also turning them counter-

clockwise.

- Turn the fastening screws (clockwise) into the (motor) flange until the nominal air gap is

reached (to be measured with feeling gauge) at three positions on the circumference.

- Reset the hollow screws, i.e. turn them out of the magnet body (clockwise) until locked

against the counter-friction surface.

- Tighten the fastening screws with the tightening torque as per 3.2.2.3.

- Subsequently control of the air gap, if necessary, carry out a readjustment

Illustration 5.1:

Readjusting the air gap

(sectional view)