NORD Drivesystems B1904 User Manual

Page 11

Operating and Installation Instructions FDB (Getriebebau NORD)

Version 08.2011

Page

11

of 23

Brake

type

N (Illustration 3.1 top)

The standard type of the spring-pressure brake is delivered with a fixed braking torque M

bN

. Via

the number of springs (item 4), this torque can be varied as per 3.2.2.1.

Brake

type

C (Illustration 3.1 bottom)

The braking torque for this brake type with central adjusting ring (item 10) is also adjustable via

the number of springs as per 3.2.2.1 similar to type N. Furthermore, it can additionally be

adjusted by screwing in and screwing out the adjusting ring. The nominal braking torque

has been adjusted as soon as the ring firmly contacts the magnet housing (item 1.2). Screwing

out will result in a step-by-step reduction of the braking torque as per 3.2.2.2.

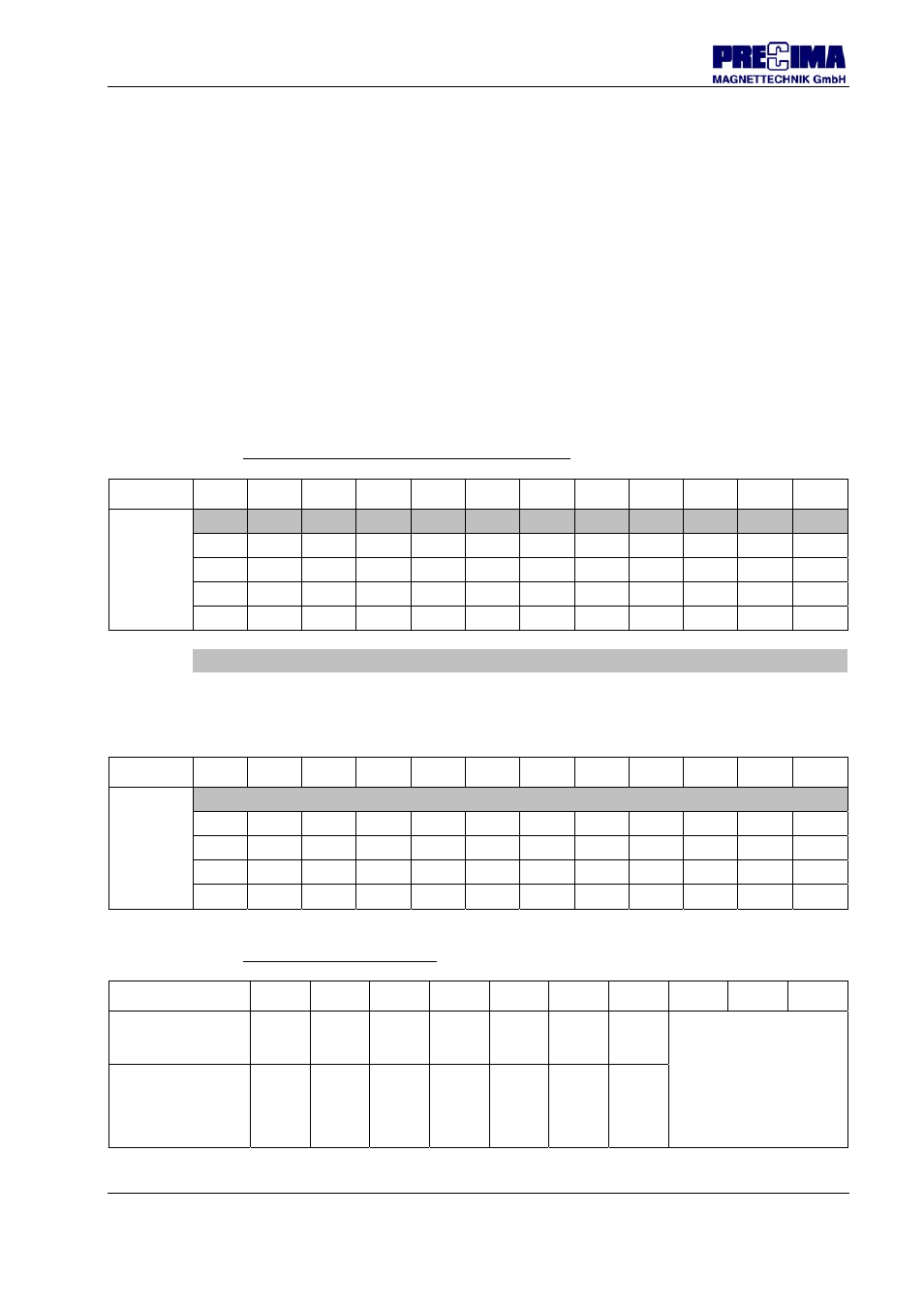

3.2.2 Technical Data

3.2.2.1 Nominal braking torques and number of springs

Size

08 10 13 15 17

20

N

20

C

23

N

23

C

26 30 40

Nominal

braking

torques

M

bN

[Nm]

7,5*

15*

30*

60*

90*

150*

150*

225*

225*

375*

600*

1500*

5 10 20 40 60 100 100 150 150 250 400 1000

3,5 7 14 28 43 70 80 107 105 187 300 850

3 6 12 23 34 57 50 85 63 125 200 675

2

4

8

17

26

42

65

500

* only with holding brake possessing emergency-stop properties

— Permissible deviations of the real braking torque:

Working brake: -30% (new) or ±20% (run-in)

Holding brake: ±20% (new) or -10/+30% (run-in) —

Size

08 10 13 15 17

20

N

20

C

23

N

23

C

26 30 40

Number

of

springs

for the

above M

bN

― Please, ask for spring quantities for nominal braking torques deviating from M

bN

―

7 7 7 7 7 7 8 7 8 8 8 12

5 5 5 5 5 5 6 5 6 6 6 10

4 4 4 4 4 4 4 4 4 4 4 8

3 3 3 3 3 3

3

6

3.2.2.2 Torque reduction (design C)

Size

08

C

10

C

13

C

15

C

17

C

20

C

23

C

26 30 40

Torque reduction

/ latching step

[Nm]

0,2 0,2 0,3 1 1,3 1,5 2

no standard design C

Number of usable

latching steps

(max. permissible

turning out the

threaded ring)

6 12 12 9 12 18 24