What is teds, Basic concept, How it works – FUTEK IHH200 Digital Display User Manual

Page 3

10 Thomas, Irvine, CA 92618

USA T (949)-465-0900 F (949)-465-0905

IHH200 Manual 2.5 - Page 3

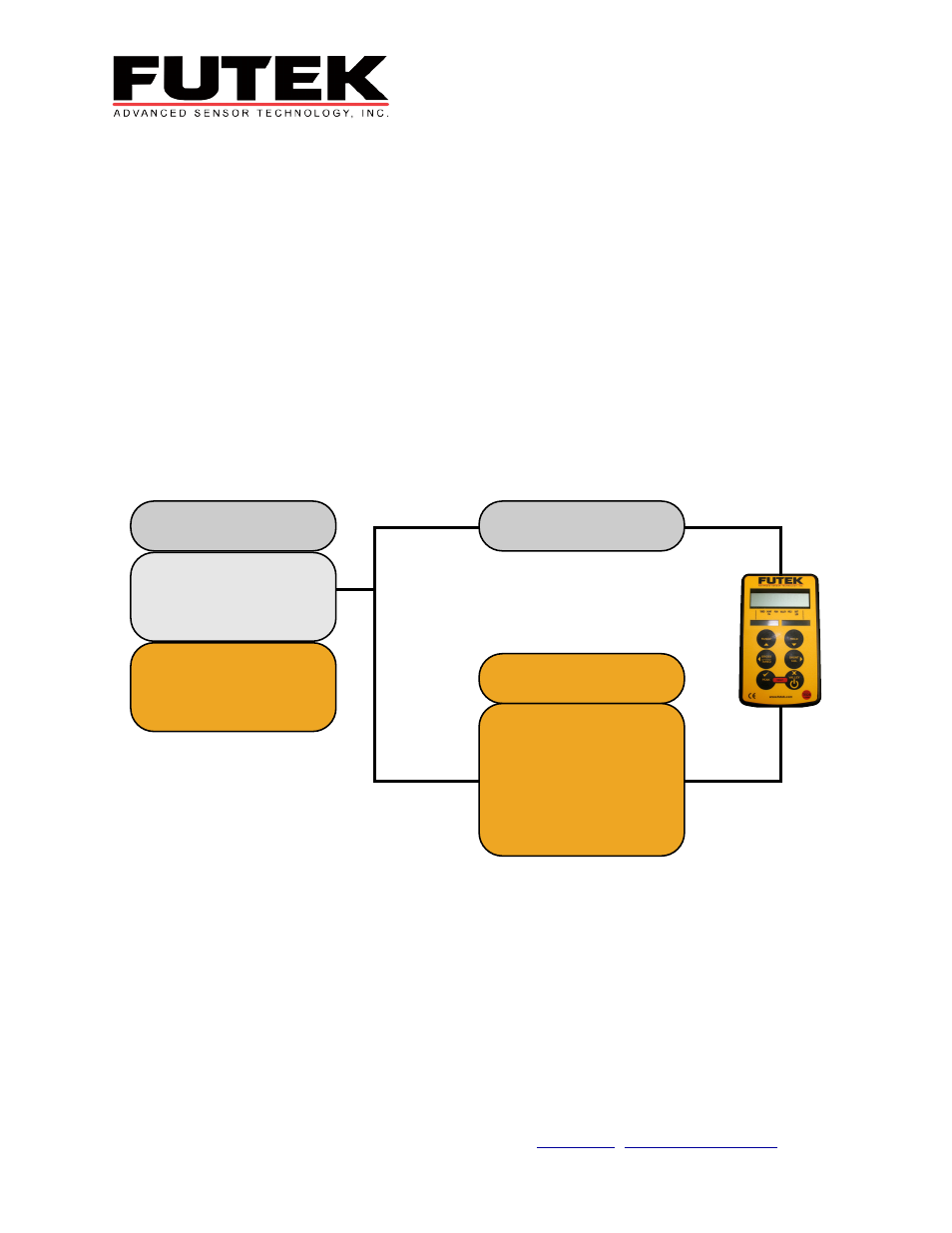

Smart TEDS Sensor

Transducer

Transducer

Electronic Data Sheet

(TEDS)

Analog Signal

Digital TEDS

Sensor Manufacturer

Serial Number

Model Number

Measurement Range

Calibration Range

User Information

Mixed-Mode Interface

(Analog & Digital)

What is TEDS?

"Plug and play sensor hardware and software make configuring a smart TEDS sensor as easy as plugging a mouse into

a PC. The technology has greatly improved efficiency and productivity by completely eliminating manual sensor

configuration."

Basic Concept

TEDS is at the heart of the new universally accepted IEEE 1451.4 standard for delivering Plug and Play capabilities to

analogue measurement and test instruments. In essence, information in a Transducer Electronic Data Sheet provides

interfacing devices with the critical sensor calibration information in order to perform accurate and precise

measurements every time.

TEDS works in a similar way in which USB computer peripherals immediately work as they are connected.

TEDS enabled equipment maybe swapped and changed without recalibration, saving time and money.

TEDS holds information such as a sensor manufacturer, model and serial numbers, and more importantly all the

calibration settings determined by the manufacturer.

How it Works

Plug and play is a data acquisition technology that can simplify the configuration of automated measuring systems by

making a sensor’s unique identification data available electronically. As implemented according to IEEE P1451.4, data in

the form of a transducer electronic data sheet (TEDS) is burned on an electrically erasable programmable read-only

memory (EEPROM) chip located on the sensor, so when a properly adapted signal conditioner interrogates the sensor, it

can interpret the self identification data. This technology provides a great benefit by eliminating the need for paper

calibration sheets. In addition, it can simplify labeling and cabling problems, as well as inventory control issue; by letting

you burn location data onto the chip when installing a sensor. And because all sensors produced according to the

standard will carry the same basic identically formatted self-identification information, you will be able to mix and match

sensors and applicable signal conditioners across manufacturers.