Bwst, bwsf and bwscap series – Blue Angel Pumps BWST50 User Manual

Page 3

3

BWST, BWSF and BWSCAP Series

www.blueangelpumps.com

specifications for cut-in/out levels.

The pump will recycle thereafter as

required.

5. Do not operate the pump unless it

is submerged in water. Dry running

causes pump failure.

6. The motor is equipped with an

automatic reset thermal protector.

7. While the pump is draining the pit,

verify that the discharge piping is

carrying the water to a point several

feet away from the foundation.

8. If pump discharge line is exposed to

freezing temperature, the exposed

line must be pitched to drain.

Trapped water will freeze and

damage the pump.

FOR BWSCAP MODELS ONLY:

9. Sump pump will turn on, when

water is about 1.5 inch from the top

of the switch.

10. Sump pump will run a minimum of 4

seconds, to a maximum of 16 before

stopping.

11. Sump pump run time will be

determined by the sump pit size and

water flow rate into the sump pit.

12. Under flooding conditions, the sump

pump will stop for 1 second, every

16 seconds, and automatically turn

back on.

Maintenance

Always

disconnect

the electrical supply before

attempting to install, service,

relocate or perform any

maintenance. If the power source is out

of sight, lock and tag in the open (off)

position to prevent unexpected power

application. Failure to do so could result

in fatal electrical shock.

Only qualifi ed electricians should repair

this unit. Improper repair could result in

fatal electrical shock.

1. Let the pump cool for a minimum of

two hours before servicing because

the pump contains hot oil under

pressure and the motor is hot.

2. Disassembly of the motor prior to

expiration of warranty will void the

warranty. If repairs are required, see

troubleshooting chart.

3. Inlet should be kept clean and free

of all foreign objects and inspect

annually. A clogged inlet will

damage pump.

4.

Pump should be checked monthly for

proper operation.

This pump contains

dielectric oil for

cooling. This oil can be harmful to

the environment. Check the state

environmental laws before disposing

this oil.

Specifications

Power supply requirements

120V, 60 hz

Motor

Single phase, oil filled

Liquid temperature range

40°F to 120°F

Circuit requirements

15 amps (min)

Dimensions

11 in. high x 9 in. base

Cut-in level (factory set)

BWST = 14" BWSF = 7”

Cut-out level (factory set)

BWST = 7”

BWSF = 2-1/2”

Construction

Motor housing

Glass reinforced thermoplastic

Volute

Thermoplastic

Impeller

Glass reinforced thermoplastic

Shaft

416 Stainless steel

Seals

Buna N

Discharge

11/2” NPT

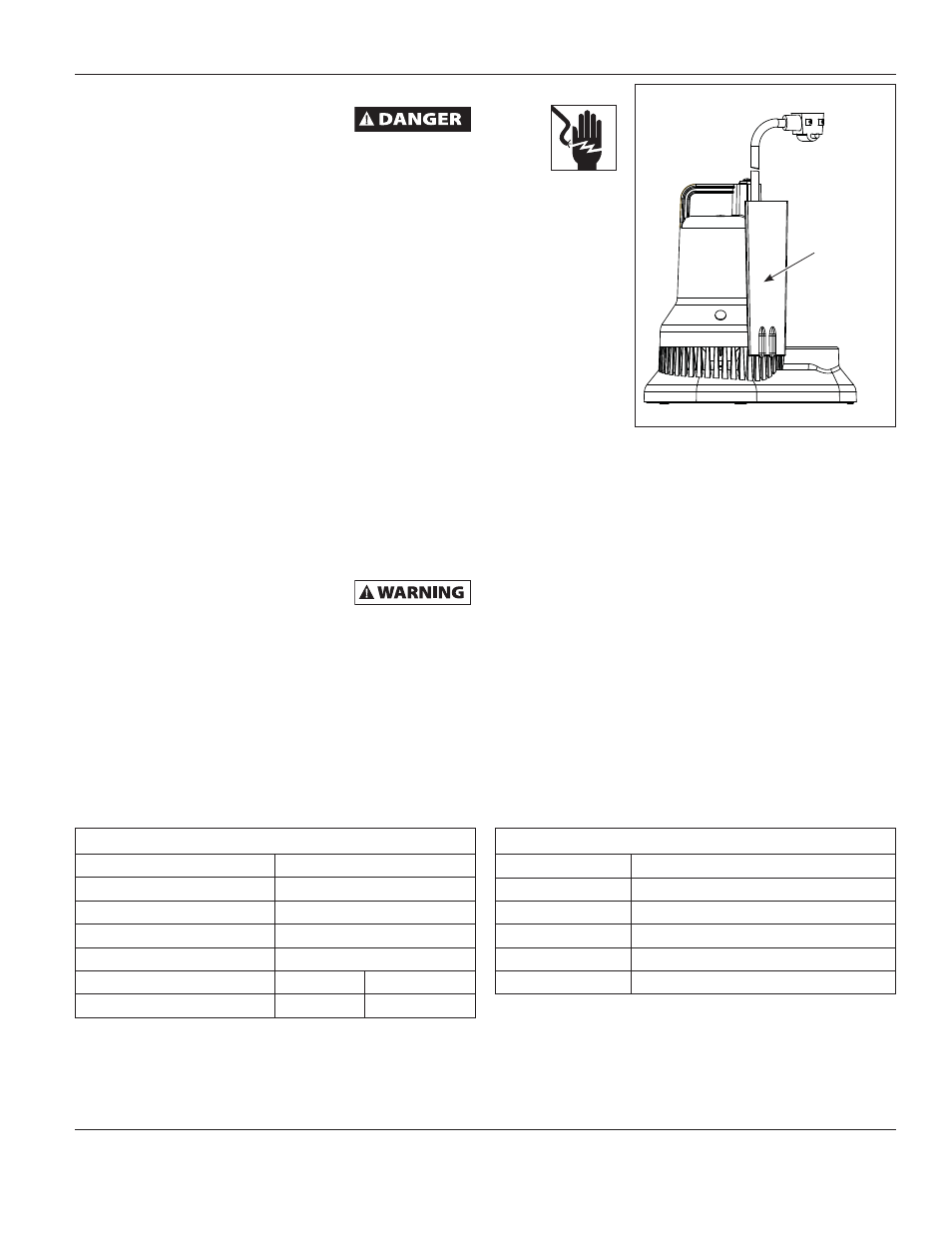

Figure 5

Working

surface to

be kept

free of

foreign

material